Abstract

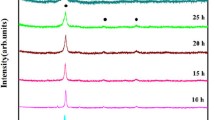

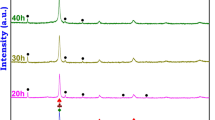

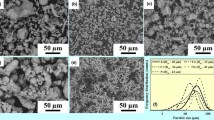

A multi-component nanocrystalline AlCrCuFeNiZn high entropy alloy with 12 nm crystallite size was successfully synthesized using high energy ball milling. The progress of solid solution formation during milling was analyzed using XRD. A major portion of the HEA is observed to be BCC in crystal structure after 30 h of milling. Thermal analysis showed that HEA powders exhibited exponential oxidation characteristics. Thermal analysis showed that low activation energy was sufficient to start recrystallization because of high energy stored in the milled powders. The crystallite size after consolidation is in nanocrystalline range due to the sluggish diffusion of atoms and nanotwinning. After consolidation, the crystallite size is around 79 nm. Samples sintered at 850 °C for 2 h exhibited high hardness values of 700 ± 15 HV1.0, major volume fraction of the phases are having FCC crystal structure along with a minor phase having BCC crystal structure. Due to positive enthalpy mixing of Cu with other elements, decomposition of BCC to new FCC phases occurs.

Similar content being viewed by others

References

C. Suryanarayana, Non-equilibrium Processing of Materials, 1st ed., Pergamon Materials Series, Oxford, 1999

J.W. Yeh, Y.L. Chen, S.J. Lin, and S.K. Chen, High Entropy Alloys—A New Era of Exploitation, Mater. Sci. Forum., 2007, 560, p 1–9

J.W. Yeh, S.K. Chen, S.J. Lin, J.T. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High Entropy Alloys with Multiple Principle Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303

H. Gleiter, Nanostructured Materials: Basic Concepts and Microstructure, Acta Mater., 2000, 48(1), p 1–29

C. Suryanarayana, Mechanical Alloying and Milling, Prog. Mater. Sci., 2001, 46(1–2), p 1–184

S. Varalakshmi, G. Appa Rao, M. Kamaraj, and B.S. Murty, Hot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic AlFeTiCrZnCu High Entropy Alloy After Mechanical Alloying, J. Mater. Sci., 2010, 45(19), p 5158–5163

Z.Z. Fang, Sintering of Advanced Materials, Woodhead Publishing, Cambridge, 2010

T.R. Malow and C.C. Koch, Grain Growth in Nanocrystalline Iron Prepared by Mechanical Attrition, Acta Mater., 1997, 45(5), p 2177–2186

V.D. Vikram, B.B. Panigrahi, M.M. Godkhindi, T.R. Rama Mohan, and P. Ramakrishnan, Dilatometry of Attrition Milled Nanocrystalline Titanium Powders, Mater. Res. Bull., 2006, 41(11), p 2111–2122

C. Kittel, Introduction to Solid State Physics, 7th ed., Wiley, New York, 1996

D.A. Porter and K.E. Easterling, Phase Transformation in Metals and Alloys, 2nd ed., Chapman & Hall, London, 1992

A. Takeuchi and A. Inoue, Mixing Enthalpy of Liquid Phase Calculated by Miedema’s Scheme and Approximated with Sub-regular Solution Model for Assessing Forming Ability of Amorphous and Glassy Alloys, Intermetallics, 2010, 18(9), p 1779–1789

C. Bansal, Z.Q. Gao, L.B. Hong, and B. Fultz, Phases and Phase Stabilities of Fe3X Alloys (X = Al, As, Ge, In, Sb, Si, Sn, Zn) Prepared by Mechanical Alloying, J. Appl. Phys., 1994, 76(10), p 5961–5966

ThH de Keijser, J.I. Langford, E.J. Mittemeijer, and A.B.P. Vogels, Use of the Voigt Function in a Single-Line Method for the Analysis of X-ray Diffraction Line Broadening, J. Appl. Crystallogr., 1982, 15, p 308–314

F.A. Mohamed, A Dislocation Model for the Minimum Grain Size Obtainable by Milling, Acta Mater., 2003, 51(14), p 4107–4119

J.Y. Huang, Y.D. Yu, Y.K. Wu, D.X. Li, and H.Q. Ye, Microstructure and Nanoscale Composition Analysis of the Mechanical Alloying of FexCu100−x (X = 16, 60), Acta Mater., 1997, 45(1), p 113–124

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, and P.V. Satyanarayana, X-ray Peak Broadening Analysis of AA 6061100−x-x wt.% Al2O3 Nanocomposite Prepared by Mechanical Alloying, Mater. Charact., 2011, 62(7), p 661–672

Y.H. Zhao, H.W. Shang, and K. Lu, Microstructure Evolution and Thermal Properties in Nanocrystalline Fe During Mechanical Attrition, Acta Mater., 2001, 49(2), p 365–375

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, and Vijay Kumar Iyer, Effect of Strengthening Mechanisms on Cold Workability and Instantaneous Strain Hardening Behavior During Grain Refinement of AA 6061-10 wt.% TiO2 Composite Prepared by Mechanical Alloying, J. Alloys Compd., 2010, 507(1), p 236–244

H.X. Sui, M. Zhu, M. Qi, G.B. Li, and D.Z. Yang, The Enhancement of Solid Solubility Limits of AlCo Intermetallic Compound by High-Energy Ball Milling, J. Appl. Phys., 1992, 71(6), p 2945–2949

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, S.W. Lee, and K. Niihara, Characterization of Nanocrystalline CoCrFeNiTiAl High-Entropy Solid Solution Processed by Mechanical Alloying, J. Alloys Compd., 2010, 495(1), p 33–38

H.E. Kissinger, Reaction Kinetics in Differential Thermal Analysis, Anal. Chem., 1957, 29(11), p 1702–1706

L.W. Crane, P.J. Dynes, and D.H. Kaelble, Analysis of Curing Kinetics in Polymer Composites, J. Polym. Sci. Polym. Lett. Ed., 1973, 11, p 533–540

J.M. Criado and A. Ortega, Non-isothermal Crystallization Kinetics of Metal Glasses: Simultaneous Determination of Both the Activation Energy and the Exponent n of the JMA Kinetic Law, Acta Mater., 1987, 35(7), p 1715–1721

B.B. Panigrahi, Sintering and Grain Growth Kinetics of Ball Milled Nanocrystalline Nickel Powder, Mater. Sci. Eng. A, 2007, 460–461, p 7–13

J.R. Groza, Nanocrystalline Powder Consolidation Methods, Nanostructured Materials: Processing, Properties and Applications, 2nd ed., C.C. Koch, Ed., William Andrew Publishing, New York, 2002, p 173–217

M.S. Senthil Saravanan, K. Sivaprasad, P. Susila, and S.P. Kumaresh Babu, Anisotropy Models in Precise Crystallite Size Determination of Mechanically Alloyed Powders, Physica B, 2011, 406(2), p 165–168

M.O. Humienik and J. Mozejko, Thermodynamic Functions of Activated Complexes Created in Thermal Decomposition Processes of Sulphates, Thermochim. Acta., 2000, 344(1–2), p 73–79

A.A. Frost and R.G. Pearson, Kinetics and Mechanisms, 2nd ed., Wiley, New York, 1961

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, H. Wang, Y.C. Wang, Q.J. Zhang, and J. Shi, Microstructure and Mechanical Properties of CoCrFeNiTiAlx High-Entropy Alloys, Mater. Sci. Eng. A., 2009, 508(1–2), p 214–219

B. Ren, Z.X. Liu, B. Cai, M.X. Wang, and L. Shi, Aging Behavior of a CuCr2Fe2NiMn High-Entropy Alloy, Mater. Des., 2012, 33, p 121–126

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov, G.A. Salishchev, and O.N. Senkov, Tensile Properties of an AlCrCuNiFeCo High-Entropy Alloy in As-Cast and Wrought Conditions, Mater. Sci. Eng. A, 2012, 533, p 107–118

H.S. Khatak and B. Raj, Corrosion of Austenitic Stainless Steels: Mechanism Mitigation and Monitoring, Woodhead Publishing, Cambridge, 2002

C.M. Lin and H.L. Tsai, Evolution of Microstructure, Hardness, and Corrosion Properties of Al0.5CoCrFeNi Alloy, Intermetallics, 2011, 19(3), p 288–294

S. Singh, N. Wanderka, B.S. Murty, U. Glatzel, and J. Banhart, Decomposition in Multi-component AlCoCrCuFeNi High-Entropy Alloy, Acta Mater., 2011, 59(1), p 182–190

T.T. Shun, C.H. Hung, and C.F. Lee, The Effects of Secondary Elemental Mo or Ti Addition in Al0.3CoCrFeNi High-Entropy Alloy on Age Hardening at 700°C, J. Alloys Compd., 2010, 495(1), p 55–58

C.W. Tsai, Y.L. Chen, M.H. Tsai, J.W. Yeh, T.T. Shun, and S.K. Chen, Deformation and Annealing Behaviors of High-Entropy Alloy Al0.5CoCrCuFeNi, J. Alloys Compd., 2009, 486(1–2), p 427–435

E.E. Danaf, S.R. Kalidindi, and R.D. Doherty, Influence of Grain Size and Stacking-Fault Energy on Deformation Twinning in FCC Metals, Metall. Mater. Trans. A, 1999, 30(5), p 1223–1233

Y. Zhang, N.R. Tao, and K. Lu, Effect of Stacking-Fault Energy on Deformation Twin Thickness in Cu–Al Alloys, Scripta Mater., 2009, 60(4), p 211–213

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koundinya, N.T.B.N., Sajith Babu, C., Sivaprasad, K. et al. Phase Evolution and Thermal Analysis of Nanocrystalline AlCrCuFeNiZn High Entropy Alloy Produced by Mechanical Alloying. J. of Materi Eng and Perform 22, 3077–3084 (2013). https://doi.org/10.1007/s11665-013-0580-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0580-5