Abstract

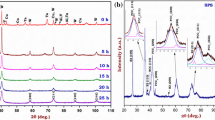

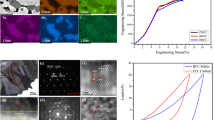

Al0.1CoCrFeNi high-entropy alloy (HEA) was synthesized successfully from elemental powders by mechanical alloying (MA) and subsequent consolidation by spark plasma sintering (SPS). The alloying behavior, microstructure, and mechanical properties of the HEA were assessed using X-ray diffraction, electron microscope, hardness, and compression tests. MA of the elemental powders for 8 h has resulted in a two-phased microstructure: α-fcc and β-bcc phases. On the other hand, the consolidated bulk Al0.1CoCrFeNi-HEA sample reveals the presence of α-fcc and Cr23C6 phases. The metastable β-bcc transforms into a stable α-fcc during the SPS process due to the supply of thermal energy. The hardness of the consolidated bulk HEA samples is found to be 370 ± 50 HV0.5, and the yield and ultimate compressive strengths are found to be 1420 and 1600 MPa, respectively. Such high strength in the Al0.1CoCrFeNi HEA is attributed to the grain refinement strengthening.

Similar content being viewed by others

References

E.P. George, D. Raabe, and R.O. Ritchie: High-entropy alloys. Nat. Rev. Mater. 4, 515 (2019).

E.P. George, W.A. Curtin, and C.C. Tasan: High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 188, 435 (2020).

D.B. Miracle and O.N. Senkov: A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448 (2017).

D.B. Miracle, J.D. Miller, O.N. Senkov, C. Woodward, M.D. Uchic, and J. Tiley: Exploration and development of high entropy alloys for structural applications. Entropy 16, 494 (2014).

R. Sokkalingam, K. Sivaprasad, M. Duraiselvam, V. Muthupandi, and K.G. Prashanth: Novel welding of Al0.5CoCrFeNi high-entropy alloy: Corrosion behavior. J. Alloys Compd. 817, 153163 (2020).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375, 213 (2004).

C. Sajithbabu, K. Sivaprasad, V. Muthupandi, and J.A. Szpunar: Characterization of nanocrystalline AlCoCrCuNiFeZn high entropy alloy produced by mechanical alloying. Procedia Mater. Sci. 5, 1020 (2014).

S. Gangireddy, B. Gwalani, V. Soni, R. Banerjee, and R.S. Mishra: Contrasting mechanical behavior in precipitation hardenable AlxCoCrFeNi high entropy alloy microstructures: Single phase FCC vs. dual phase FCC-BCC. Mater. Sci. Eng. A 739, 158 (2019).

N. Kumar, Q. Yinh, X. Nie, R.S. Mishra, Z. Tang, P.K. Liaw, R.E. Brennan, K.J. Dohetry, and K.C. Cho: High strain-rate compressive deformation behavior of Al0.1CrFeCoNi high entropy alloy. Mater. Des. 86, 598 (2015).

S. Gangireddy, B. Gwalani, K. Liu, R. Banerjee, and R.S. Mishra: Microstructures with extraordinary dynamic work hardening and strain rate sensitivity in Al0.3CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 734, 42 (2018).

S. Gangireddy, L. Kaimiao, B. Gwalani, and R.S. Mishra: Microstructural dependence of strain rate sensitivity in thermomechanically processed Al0.1CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 727, 148 (2018).

W.R. Wang, W.L. Wang, and J.W. Yeh: Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J. Alloys Compd. 589, 143 (2014).

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie: A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153 (2014).

C.J. Tong, M.R. Chen, J.W. Yeh, S.J. Lin, S.K. Chen, T.T. Shun, and S.Y. Chang: Mechanical performance of the AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall. Mater. Trans. A 36, 1263 (2005).

R. Sokkalingam, S. Mishra, S.R. Cheethirala, V. Muthupandi, and K. Sivaprasad: Enhanced relative slip distance in gas-tungsten-arc-welded Al0.5CoCrFeNi high-entropy alloy. Metall. Mater. Trans. A 48, 3630 (2017).

D.Y. Li and Y. Zhang: The ultrahigh charpy impact toughness of forged AlxCoCrFeNi high entropy alloys at room and cryogenic temperatures. Intermetallics 70, 24 (2016).

Y. Sun, P. Chen, L. Liu, M. Yan, X. Wu, C. Yu, and Z. Liu: Local mechanical properties of AlxCoCrCuFeNi high entropy alloy characterized using nanoindentation. Intermetallics 93, 85 (2018).

R. Sokkalingam, V. Muthupandi, K. Sivaprasad, and K.G. Prashanth: Dissimilar welding of Al0.1CoCrFeNi high-entropy alloy and AISI304 stainless steel. J. Mater. Res. 34, 2683 (2019).

Y. Lv, R. Hu, Z. Yao, J. Chen, D. Xu, Y. Liu, and X. Fan: Cooling rate effect on microstructure and mechanical properties of AlxCoCrFeNi high entropy alloys. Mater. Des. 132, 292 (2017).

J. Karimi, P. Ma, Y.D. Jia, and K.G. Prashanth: Linear patterning of high entropy alloy by additive manufacturing. Manuf. Lett. 24, 9 (2020).

Y. Shi, L. Collins, R. Feng, C. Zhang, N. Balke, P.K. Liaw, and B. Yang: Homogenization of AlxCoCrFeNi high-entropy alloys with improved corrosion resistance. Corr. Sci. 133, 120 (2018).

R. Sokkalingam, K. Sivaprasad, M. Duraiselvam, V. Muthupandi, and K.G. Prashanth: Novel welding of Al0.5CoCrFeNi high-entropy alloy: Corrosion behavior. J. Alloys Compd. 817, 153163 (2020).

J. Joseph, N. Haghdadi, K. Shamlaye, P. Hodgson, M. Barnett, and D. Fabijanic: The sliding wear behaviour of CoCrFeMnNi and AlxCoCrFeNi high entropy alloys at elevated temperatures. Wear 428–429, 32 (2019).

N. Kumar, M. Komarasamy, P. Nelaturu, Z. Tang, P.K. Liaw, and R.S. Mishra: Friction stir processing of a high entropy alloy Al0.1CoCrFeNi. JOM 67, 1007 (2015).

R. Sokkalingam, P. Mastanaiah, V. Muthupandi, K. Sivaprasad, and K.G. Prashanth: Electron beam welding of high entropy alloy and stainless steel: Microstructure and mechanical properties. Mater. Manuf. Process. (2020). doi: 10.1080/10426914.2020.1802045

S.Q. Xia, X. Yang, T.F. Yang, S. Liu, and Y. Zhang: Irradiation resistance in AlxCoCrFeNi high entropy alloys. JOM 67, 2340 (2015).

T. Yang, S. Xia, S. Liu, C. Wang, S. Liu, Y. Fang, Y. Zhang, J. Xue, S. Yan, and Y. Wang: Precipitation behavior of AlxCoCrFeNi high entropy alloys under ion irradiation. Sci. Rep. 6, 32146 (2016).

R.B. Nair, H.S. Arora, S. Mukherjee, S. Singh, H. Singh, and H.S. Grewal: Exceptionally high cavitation erosion and corrosion resistance of a high entropy alloy. Ultrason. Sonochem. 41, 252 (2018).

R. Li, J. Hou, W. Yang, H. Yu, Q. Wang, and Z. Zhang: Strengthening mechanism and yield strength prediction of cold-drawn commercially pure aluminum wire. IOP Conf. Ser. Mater. Sci. Eng. 382, 022094 (2018).

S.W. Wu, G. Wang, J. Yi, Y.D. Jia, I. Hussain, Q.J. Zhai, and P.K. Liaw: Strong grain-size effect on deformation twinning of an Al0.1CoCrFeNi high-entropy alloy. Mater. Res. Lett. 5, 276 (2017).

Z. Fu, W. Chen, H. Wen, D. Zhang, Z. Chen, B. Zheng, Y. Zhou, and E.J. Lavernia: Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 107, 59 (2016).

Z. Wang, R.T. Qu, S. Scudino, B.A. Sun, K.G. Prashanth, D.V. Louzguine-Luzgin, M.W. Chen, Z.F. Zhang, and J. Eckert: Hybrid nanostructured aluminum alloy with super-high strength. NPG Asia Mater. 7, e229 (2015).

T. Maity, K.G. Prashanth, O. Balci, J.T. Kim, T. Schoeberl, Z. Wang, and J. Eckert: Influence of severe straining and strain rate on the evolution of dislocation structures during micro-/nanoindentatoin in high entropy lamellar eutectics. Int. J. Plasticity 109, 121 (2018).

K.G. Prashanth, S. Scudino, H.J. Klauss, K.B. Surreddi, L. Loeber, Z. Wang, A.K. Chaubey, U. Kuehn, and J. Eckert: Microstructure and mechanical properties of Al-12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 590, 153 (2014).

X.D. Xu, P. Liu, A. Hirata, S.X. Song, T.G. Nieh, and M.W. Chen: Microstructural origins for a strong and ductile Al0.1CoCrFeNi high-entropy alloy with ultrafine grains. Materialia 4, 395 (2018).

Z. Wang, J. Tan, S. Scudino, B.A. Sun, R.T. Qu, J. He, K.G. Prashanth, W.W. Zhang, Y.Y. Li, and J. Eckert: Mechanical behavior of Al-based matrix composites reinforced with Mg58Cu28.5Gd11Ag2.5 metallic glass. Adv. Powder Technol. 25, 635 (2014).

Z. Wang, K.G. Prashanth, S. Scudino, A.K. Chaubey, D.J. Sordelet, W.W. Zhang, Y.Y. Li, and J. Eckert: Tensile properties of Al matrix composites reinforced with in situ devitrified Al84Gd6Ni7Co3 glassy particles. J. Alloys Compd. 586, S419 (2014).

F. Ali, S. Scudino, G. Liu, V.C. Srivastava, N.K. Mukhopadhyay, M. Samadi Khoshkhoo, K.G. Prashanth, V. Uhlenwinkel, M. Calin, and J. Eckert: Modeling the strengthening effect of Al–Cu–Fe quasicrystalline particles in Al-based metal matrix composites. J. Alloys Compd. 536S, S130 (2012).

K.G. Prashanth, S. Scudino, A.K. Chaubey, L. Loeber, P. Wang, H. Attar, F.P. Schimansky, F. Pyczak, and J. Eckert: Processing of Al-12Si-TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 31, 55 (2016).

N. Singh, S. Banerjee, O. Parkash, and D. Kumar: Tribological and corrosion behavior of (100-x)(Fe70Ni30)-(x)ZrO2 composites synthesized by powder metallurgy. Mater. Chem. Phys. 205, 261 (2018).

K.G. Prashanth, S. Scudino, and J. Eckert: Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 126, 25 (2017).

K.G. Prashanth, S. Kolla, and J. Eckert: Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting—selection guidelines. Materials 10, 672 (2017).

K.G. Prashanth, H. Shakur Shahabi, H. Attar, V.C. Srivastava, N. Ellendt, V. Uhlenwinkel, J. Eckert, and S. Scudino: Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 6, 1 (2015).

N. Singh, R. Ummethala, P. Hameed, R. Sokkalingam, and K.G. Prashanth: Competition between densification and microstructure of functional materials by selective laser melting. Mater. Des. Process. Comm. 2, e146 (2020).

C. Suryanarayana: Mechanical alloying and milling. Prog. Mater. Sci. 46, 1 (2001).

K.G. Prashanth: Influence of mechanical activation on decomposition of titanium hydride. Mater. Manuf. Process. 25, 974 (2010).

Z. Wang, K.G. Prashanth, S. Scudino, J. He, W.W. Zhang, Y.Y. Li, M. Soica, G. Vaughan, D.J. Sordelet, and J. Eckert: Effect of ball milling on structure and thermal stability of Al84Gd6Ni7Co3 glassy powders. Intermetallics 46, 97 (2014).

T. Maity, K.G. Prashanth, A. Janda, J.T. Kim, F. Spieckermann, and J. Eckert: Mechanism of high-pressure torsion-induced shear banding and lamellar thickness saturation in Co–Cr–Fe–Ni–Ng high-entropy composites. J. Mater. Res. 34, 2672 (2019).

T. Maity, K.G. Prashanth, O. Balci, Z. Wang, Y.D. Jia, and J. Eckert: Plastic deformation mechanisms in severely strained eutectic high entropy composites explained via strain rate sensitivity and activation volume. Comp. Part B 150, 7 (2018).

P.F. Yu, H. Cheng, L.J. Zhang, H. Zhang, Q. Jing, M.Z. Ma, P.K. Liaw, G. Lia, and R.P. Liu: Effects of high-pressure torsion on microstructures and properties of an Al0.1CoCrFeNi high-entropy alloy. Mater. Sci. Eng. A 655, 283 (2016).

A.K. Chaubey, S. Scudino, K.G. Prashanth, and J. Eckert: Microstructure and mechanical properties of Mg–Al-based alloy modified with cerium. Mater. Sci. Eng. A 625, 46 (2015).

E.Y. Gutmanas: Materials with fine microstructure by advanced powder metallurgy. Prog. Mater. Sci. 34, 261 (1990).

D. Marko, K.G. Prashanth, S. Scudino, Z. Wang, N. Ellendt, V. Uhlenwinkel, and J. Eckert: Al-based metal matrix composites reinforced with Fe49.9Co35.1Nb7.7B4.5Si2.8 glassy powder: Mechanical behavior under tensile loading. J. Alloys Compd. 615, S382 (2014).

A.K. Chaubey, S. Scudino, M.S. Khoshkhoo, K.G. Prashanth, N.K. Mukhopadhyay, B.K. Mishra, and J. Eckert: High-strength ultrafine grain Mg–7.4%Al alloy synthesized by consolidation of mechanically alloyed powders. J. Alloys Compd. 610, 456 (2014).

P. Molaiyan and R. Witter: Mechanochemical synthesis of solid-state electrolyte Sm1−xCaxF3−x for batteries and other electrochemical devices. Mater. Lett. 244, 22 (2019).

K.G. Prashanth and B.S. Murty: Production, kinetic study and properties of Fe-based glass and its composites. Mater. Manuf. Process. 25, 592 (2010).

P. Susila, D. Sturm, M. Heilmaier, B.S. Murty, and V.S. Sarma: Effect of yttria particle size on the microstructure and compression creep properties of nanostructured oxide dispersion strengthened ferritic (Fe–12Cr–2W–0.5Y2O3) alloy. Mater. Sci. Eng. A 528, 4579 (2011).

K.G. Prashanth, S. Scudino, K.B. Surreddi, M. Sakaliyska, B.S. Murty, and J. Eckert: Crystallization kinetics of Zr65Ag5Cu12.5Ni10Al7.5 glassy powders produced by ball milling of pre-alloyed ingots. Mater. Sci. Eng. A 513, 279 (2009).

X. Liu, L. Zhang, and Y. Xu: Microstructure and mechanical properties of graphene reinforced Fe50Mn30Co10Cr10 high-entropy alloy composites synthesized by MA and SPS. Appl. Phys. A 123, 567 (2017).

P. Molaiyan and R. Witter: Crystal phase and surface defect driven synthesis of Pb1−xSnxF2 solid solution electrolyte for fluoride ion batteries. J. Electroanal. Chem. 845, 154–159 (2019).

P.V. Satyanarayana, R. Sokkalingam, P.K. Jena, K. Sivaprasad, and K.G. Prashanth: Tungsten matrix composite reinforced with CoCrFeMnNi high-entropy alloy: Impact of processing routes on microstructure and mechanical properties. Metals 9, 992 (2019).

O. Guillon, J. Gonzalez-Julian, B. Dargatz, T. Kessel, G. Schierning, J. Rathel, and M. Herrmann: Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments. Adv. Eng. Mater. 16, 830 (2014).

Z.Y. Hu, Z.H. Zhang, X.W. Cheng, F.C. Wang, Y.F. Zhang, and S.L. Li: A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 191, 108662 (2020).

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Z. Fu: Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics 56, 24 (2015).

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi, and H.R. Ammar: Synthesis, structure, and mechanical response of Cr0.26Fe0.24Al0.5 and Cr0.15Fe0.14Al0.30Cu0.13Si0.28 nanocrystallite entropy alloys. Adv. Powder Technol. 31, 2161 (2020).

Y.L. Chen, Y.H. Hu, C.A. Hsieh, J.W. Yeh, and S.K. Chen: Competition between elements during mechanical alloying in an octonary multi-principal-element alloy system. J. Alloys Compd. 481, 768 (2009).

Y. Xie, H. Cheng, Q. Tang, W. Chen, W. Chen, and P. Dai: Effects of N addition on microstructure and mechanical properties of CoCrFeNiMn high entropy alloy produced by mechanical alloying and vacuum hot pressing sintering. Intermetallics 93, 228 (2018).

S. Praveen, A. Anupam, T. Sirasani, B.S. Murty, and R.S. Kottada: Characterization of oxide dispersed AlCoCrFe high entropy alloy synthesized by mechanical alloying and spark plasma sintering. Trans. Indian Inst. Met. 66, 369 (2013).

S. Praveen, A. Anupam, R. Tilak, and R.S. Kottada: Phase evolution and thermal stability of AlCoCrFe high entropy alloy with carbon as unsolicited addition from milling media. Mater. Chem. Phys. 210, 57 (2018).

H. Cheng, W. Chen, X. Liu, Q. Tang, Y. Xie, and P. Dai: Effect of Ti and C additions on the microstructure and mechanical properties of the FeCoCrNiMn high-entropy alloy. Mater. Sci. Eng. A 719, 192 (2018).

R.M. Pohan, B. Gwalani, J. Lee, T. Alam, J.Y. Hwang, H.J. Ryu, R. Banerjee, and S.H. Hong: Microstructures and mechanical properties of mechanically alloyed and spark plasma sintered Al0.3CoCrFeMnNi high entropy alloy. Mater. Chem. Phys. 210, 62 (2018).

M. Vaidya, G.M. Muralikrishna, and B.S. Murty: High-entropy alloys by mechanical alloying: A review. J. Mater. Res. 34, 664 (2019).

L. Rogal, Z. Szklarz, P. Bobrowski, D. Kalita, G. Garzeł, A. Tarasek, M. Kot, and M. Szlezynger: Microstructure and mechanical properties of Al–Co–Cr–Fe–Ni base high entropy alloys obtained using powder metallurgy. Met. Mater. Int. 25, 930 (2019).

D. Wen, B. Jiang, Q. Wang, F. Yu, X. Li, R. Tang, R. Zhang, G. Chen, and C. Dong: Influences of Mo/Zr minor-alloying on the phase precipitation behavior in modified 310S austenitic stainless steels at high temperatures. Mater. Des. 128, 34 (2017).

F. Peyrouzet, D. Hachet, R. Soulas, C. Navone, S. Godet, and S. Gorsse: Selective laser melting of Al0.3CoCrFeNi high-entropy alloy: Printability, microstructure, and mechanical properties. JOM 71, 3443 (2019).

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi, and H.R. Ammar: Manufacturing methods, microstructural and mechanical properties evolutions of high-entropy alloys: A review. Met. Mater. Int. 26, 1099 (2020).

R. Sriharitha, B.S. Murty, and R.S. Kottada: Thermal stability and strengthening in spark plasma sintered AlxCoCrCuFeNi high entropy alloys. J. Alloys Compd. 583, 419 (2014).

B. Gwalani, R.M. Pohan, J. Lee, B. Lee, R. Banerjee, H.J. Ryu, and S.H. Hong: High-entropy alloy strengthened by in situ formation of entropy-stabilized nano-dispersoids. Sci. Rep. 8, 14085 (2018).

Acknowledgments

The authors acknowledge the financial support from the Estonian Research Council through the projects IUT 19-29 and PRG 665.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sokkalingam, R., Tarraste, M., Surreddi, K.B. et al. Powder metallurgy of Al0.1CoCrFeNi high-entropy alloy. Journal of Materials Research 35, 2835–2847 (2020). https://doi.org/10.1557/jmr.2020.272

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.272