Abstract

In this study, a high temperature in-situ route is reported for the synthesis of one dimensional carbon nitride supported bismuth sulfide nanoparticles. The x-ray diffraction study confirmed the formation of orthorhombic crystal structure of bismuth sulfide with the space group of Pnma (62). The synthesized product was used as an electrode material for supercapacitor application. Electrochemical performance of the three-electrode configuration demonstrated the specific capacitance value of 190 F.g−1 at the current density 1.5 A.g−1. A symmetric supercapacitor device, fabricated using identical synthesized material, resulted a specific capacity of 101.7 mAh.g−1 at 0.02 A.g−1, with energy and power density values of 24.35 mWh.kg−1 and 186.57 W.kg−1, respectively. The symmetric device also exhibited excellent cycling stability that retained 99% of its initial capacity after 500 cycles at 0.12 A.g−1. The coin cell based symmetric supercapacitor can generate the low frequency waveform and functioned as an oscillator.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The size and shape of the materials have substantial impact on their physical and chemical properties.1 Fabrication of nanostructure with desired size and shape is a prerequisite condition for application point of view. Such nanostructures offer great potential for various practical applications in electronics,2 photonics,3 nonlinear optics,4 optoelectronics,5 biochemical sensors,6 magnetics7 and energy storage.8 Among the various nanostructured materials, sulfide based nanomaterials have appeared as prospective candidates for various energy storage applications. The transition metal sulfides, such as sulfides of zinc, cadmium, copper, cobalt, nickel, iron, manganese etc., have commonly reported of their potential application as energy storage materials.9,10,11,12,13,14 Apart from the abovementioned candidates, the sulfides of tin,15 antimony16 and bismuth17 are also attractive materials for related applications.

Bismuth-based compounds have been widely used as catalyst, gas sensor, optical and energy storage applications due to their high oxygen-conducting performance, good photocatalytic and dielectric behavior.18,19,20,21,22 For supercapacitor application, bismuth based compounds demonstrated high capacitance and superior rate performance.23,24 Supercapacitors are fascinating electrochemical energy-storage devices with higher power density than batteries.25 Sonochemical route was reported for the synthesis of spherical bismuth tungstate nanoparticles, which showed specific capacitance value of 304 F.g−1 at a current density of 3 mA.cm−2.26 Bismuth ferrite nanoflakes, synthesized using electrodeposition technique, exhibited specific capacitance value of 72.2 F.g−1 at a current density of 1.0 A.g−1 with moderate cycling stability.27 Three dimensional hierarchical structure of bismuth-based compounds, with different sizes and morphologies, exhibited high specific capacitance and superior rate capability under alkaline condition.28 Nanosized bismutite (Bi2O2CO3) with diverse morphologies exhibited excellent adsorption capabilities for anionic dyes and high photocatalytic performance for the cationic dyes under simulated solar illumination.29 The electrochemical performance of bismutite also showed good capacitance properties and could be applied as a potential candidate for energy related applications.29 Nanoporous stainless steel supported copper-bismuth oxide (CuBi2O4) was employed as a binder-free electrode for supercapacitor application that exhibited a maximum specific capacitance of 647 F.g−1 at a current density of 1.0 A.g−1 under alkaline condition.30 Bismuth molybdate nanowire, synthesized using electrodeposition technique, based electrode exhibited a maximum specific capacitance of 1075 F.g−1 at the current density of 0.1 A.g−1.31 A complexation mediated route was reported for the synthesis of bismuth oxide nanoparticles and employed for supercapacitor application in presence of alkaline electrolyte. The above system exhibited a specific capacitance 407 F.g−1 along with the energy density value 113 Wh.kg−1 at the current density of 1 A.g−1.32

Among the various bismuth based materials, bismuth sulfide is one of the significant compounds that has received much attention due to its fascinating performance in drug delivery,33 photovoltaic,34 photocatalysis,35 sensing,36 water splitting,37 hydrogen storage,38 thermoelectric,39 batteries40 and supercapacitors.41 In this current study, a high temperature in-situ protocol was applied for the synthesis of one dimensional carbon nitride supported bismuth sulfide nanoparticles (CNBS). The sulfide nanoparticles within the size range from 10 to 30 nm are dispersed throughout the support material. The synthesized product was implemented as a supercapacitor and designed for low-frequency oscillator application.

Experimental

Materials and Methods

All the compounds used in this experiment were of analytical grade and used without additional purification.

Synthesis of CNBS

In a typical experiment, bismuth (III) nitrate, thiourea and melamine in a ratio of 2: 10: 1 (by weight), respectively, was grinded thoroughly and transferred to a specially designed quartz made reaction chamber. The reaction chamber was placed inside a programmable furnace under 550°C for 4 h in presence of nitrogen atmosphere and cooled down to room temperature. A solid power (CNBS) was recovered from the reaction chamber and characterized using different analytical techniques.

Material Characterization

The as synthesized material was characterized with transmission electron microscopy (TEM, JEOL, JEM-2100), x-ray photoelectron spectroscopy (VG Multi Lab 2000) and x-ray diffraction spectroscopy (Philips PANanalytical X’pert) techniques.

Working Electrode Preparation for Three Electrode System

A slurry was prepared using CNBS, carbon black and Nafion, with the ratio of 80:10:10 (by weight), respectively, in presence of ethyl acetate as a solvent. The slurry was applied on the surface of the glassy carbon electrode and allowed to dry. A platinum wire and saturated calomel electrode were served as the counter electrode and reference electrode, respectively. The experiments for the three-electrode system were performed in presence of 2 M KOH electrolyte.

Preparation of Symmetric Coin Cell Device for Two Electrode System

A small piece of printing paper was soaked with an aqueous solution of polyvinyl alcohol (PVA) and placed in an oven at 60 °C. A thin layer of gold was deposited on the PVA coated paper using Emscope SC500. A slurry made with CNBS, carbon black and polyvinylidene fluoride, with the ratio of 80:10:10 (by weight), respectively, in presence of N-methyl-2-pyrrolidone, was deposited on the gold coated paper and applied as an electrode for the supercapacitor application. A piece of filter paper, previously soaked in 2 M of a KOH solution, was placed between two identical sets of gold deposited paper based electrodes and inserted into a coin cell.

Electrochemical Characterization

The electrochemical characterization was performed using a Biologic SP 300 potentiostat. Cyclic voltammetry (CV) study was performed under the scan rate from 20 mV.s−1 to 200 mV.s−1 within the potential range from − 1.1 to 0.1 V. A symmetric coin cell device was built for two-electrode experiments using 2 M KOH electrolyte. The CV analysis for two electrode system was performed at various scan rates ranging from 20 to 200 mV.s−1 under the operating potential of 0.0–1.5 V. The mass loading of active materials was ~ 0.2 mg for three electrode system and ~ 4.0 mg for the two electrode system. Galvanostatic charge discharge (GCD) studies were executed at the current density ranging from 1.5 to 4.0 A.g−1 and 0.025–0.25 A.g−1 under the working potentials ranging from − 1.1 to 0.1 V and from 0.0 to 1.5 V for the three-electrode and two-electrode systems, respectively. The electrochemical impedance spectroscopy measurement was performed under an open circuit voltage within the frequency range from 10 mHz to 100 kHz for two electrode system. The oscillator circuit was constructed using the symmetric device (coin cell), resistor and operational amplifier (op-amp) to generate low-frequency square and triangular waveforms. The output waveforms of the circuit were observed using a digital storage oscilloscope (Tektronix).

Result and Discussion

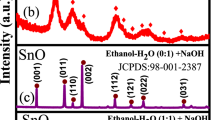

The structure of the synthesized material was evaluated using x-ray diffraction (XRD) technique, Fig. 1. The XRD pattern of the material within the range from 20 to 60°, matched with JCPDS: 17-0320, indicates the formation of bismuth sulfide. The major peaks are marked with their respective hkl values according to the entry number. The synthesized bismuth sulfide belongs to the orthorhombic crystal structure with the space group of Pbnm (62).17 The cell parameters are a = 11.1 Å, b = 11.3 Å, c = 3.9 Å, and α = β = γ = 90°, with a cell volume of approximately 501.7 Å3. The peak, positioned at 27.2°, corresponding to the (002) plane, is a characteristic interlayer stacking of conjugated aromatic systems, which can be indexed to the interlayer diffraction of crystal planes of the hexagonal phase of graphitic carbon nitride structure.42 The plane (002) of carbon nitride is superimposed with (021) plane of bismuth sulfide. The unit cell representation of bismuth sulfide, Bi2S3, is projected along b-axis, where bismuth ion occupy two different lattice sites, Bi1 (red) and Bi2 (green) and interconnected with sulphur, S, (blue) in BiS7 polyhedra network, Fig. 1, inset. The transmission electron microscopy (TEM) image, Fig. 2a shows the one dimensional architecture of the carbon nitride. In the magnified TEM image, spherical bismuth sulfide nanoparticles within the size range from 10 to 30 nm are clearly visible on the carbon nitride support, Fig. 2b. Fig. 2C displays the TEM image of a freestanding bismuth sulfide nanoparticle where the lattice fringes are clearly visible with the d-spacings value of 0.352 nm, corresponding to {130} crystal plane at 25.2° (2θ). Figure 2c, inset, exhibited selected electron area diffraction pattern and the respective orientation.

The x-ray photoelectron spectroscopy (XPS) study was performed to extract further information about the structure of the synthesized material, content of the respective elements and their oxidation states. The XPS survey spectrum, within the range from 0 to 1000 eV, Fig. 3a, suggests the presence of bismuth, sulfur, carbon and nitrogen. The spectrum within the range from 156 to 166.5 eV, after deconvolution, exhibited four peaks, Fig. 3b. The two major peaks, centered at 158.4 and 163.9 eV are attributed to the Bi 4f7/2 and Bi 4f5/2, respectively, indicates the presence of Bi3+ state.43,44 The other two small peaks at 160.9 and 162.1 eV, in between the major peaks, related to S 2p3/2 and S 2p1/2, respectively.44 The existence of these species indicates that the sulfur atoms combine with bismuth. An asymmetric broad peak for nitrogen (N 1 s) was noticed within the region from 396 to 402.6 eV, Fig. 3c. The broad peak was deconvoluted into three peaks, centered at 398.6, 399.4, and 400.7 eV, indicate the presence of pyridine-N, pyrrolic-N and graphitic-N, respectively, in the graphitic form of carbon nitride.45,46 High resolution C1s spectrum, Fig. 3d, within the range from 282 to 292 eV was deconvoluted and showed a small peak at 286.4 eV, which could be contributed from C-NH2. Other two prominent peaks at 284.6 and 288.4 eV are originated due to C-C and N-C = N, respectively.45,46

Electrochemical Performance of the Three Electrode System

The cyclic voltammograms of the CNBS modified glassy carbon electrode, within the potential range from − 1.1 to 0.1 V, under the scan rates ranging from 20 to 200 mV.s−1, in presence of 2 M KOH, are shown in Fig. 4a. The redox responses, induced by the reversible conversion of \({{\text{Bi}}}_{2}{{\text{S}}}_{3}+{{\text{OH}}}^{-}\leftrightarrow {{\text{Bi}}}_{2}{{\text{S}}}_{3}{\text{OH}}+{{\text{H}}}_{2}{\text{O}}+{{\text{e}}}^{-},\) clearly detected in the voltammograms of the CNBS modified electrode, indicating the pseudocapacitive behavior governed by the redox-based faradaic reactions.47 The shifting of redox peaks under the incremental scan rates indicate the increase of the internal diffusion resistances in the electrodes.48 To determine the specific capacitance of CNBS, galvanostatic charge-discharge measurement was conducted within the potentials range from − 1.1 to 0.1 V under the current densities from 4.0 to 1.5 A.g−1, Fig. 4b (in semi-log scale). The maximum specific capacitance value 190 F.g−1 was obtained at 1.5 A.g−1 and the specific capacitance values decreased with increasing current density, Fig. 4c, main panel. To examine the stability of the CNBS modified electrode, we performed galvanostatic charge-discharge experiments for 1000 cycles at the current density of 3.0 A.g−1 in the presence of 2 M KOH. The CNBS modified electrode demonstrated long-term stability, retaining 90% of the original specific capacitance value, Fig. 4c, inset. The decrease in specific capacitance with cycle number could be due to the loss of active material caused by the dissolution in the electrolyte and/or detachment from the electrode surface.49 Further, to determine the stability of the charge-discharge cycles of the modified electrode, cumulative probability distribution (statistics) study was performed for 1000 cycles, Fig. 4d. From the cumulative probability distribution, the mean (μ) and standard deviation (σ) are estimated as 52.20 F.g−1 and 0.23 F.g−1, respectively, Fig. 4d, inset. The calculated coefficient of variance, σ/μ (%), is 0.4%, suggested high stability of the modified electrode. The variation of energy density and power density as a function of current density, derived from galvanostatic charge-discharge curves, is displayed in Fig. 5a. The energy and power density values are obtained 7.61 Wh.kg−1 and 2193.36 W.kg−1, respectively, at the current density of 4.0 A.g−1. At the current density of 1.5 A.g−1, the values of energy density and power density are found to be 23.56 Wh.kg−1 and 557.38 W.kg−1, respectively. We further analyzed the capacitance contributions from fast and slow kinetic processes from the cyclic voltammograms under various scan rates.50,51 At a fixed potential and scan rate, the current density, \(i,\) is composed of two terms related to scan rate, \(v\), and expressed by the equation, \(i={k}_{1}v+ {k}_{2}{v}^{1/2},\) where \({k}_{1}\) and \({k}_{2}\) are constants. The terms \({k}_{1}v\) and \({k}_{2}{v}^{1/2}\) represent the current contribution of fast kinetic (capacitive controlled) and slow kinetic (diffusion controlled) processes, respectively. Dividing \({v}^{0.5}\) on both sides and plotting \(i{v}^{-0.5}\) as a function of \({v}^{0.5}\), we have determined \({k}_{1}\) (slope, 0.08) and \({k}_{2}\)(intercept, 0.31). A bar graph, Fig. 5b, demonstrate the capacitive and diffusion contribution (in %) of the total specific capacitance under different scan rates. At 20 mV.s−1, the electrode has a capacitive contribution of 53.57%, which increases to 78.49% at 200 mV.s−1. The decrease of diffusive contribution with increasing scan rate was due to the limited time of interaction between electrolyte and electrode material.

(a) Cyclic voltammograms of the CNBS modified glassy carbon electrode, within the potential range from − 1.1 to 0.1 V, under the scan rates ranging from 20 mV.s−1 to 200 mV.s−1, in presence of 2 M KOH. (b) Galvanostatic charge-discharge profile within the potentials range from − 1.1 to 0.1 V under the current densities from 4.0 A.g−1 to 1.5 A.g−1 (in semi-log scale). (c) The graphical representation of specific capacitance as a function of current density (main panel). Galvanostatic charge-discharge cycles (103) at the current density of 3.0A.g−1, which retained 90% of the original specific capacitance value (inset). (d) Cumulative probability distribution statistics of the charge-discharge cycles (main panel) with the calculation of coefficient of variance (inset).

Electrochemical Properties of the Symmetric Supercapacitor

To fabricate a symmetric coin cell, equivalent mass ratios of CNBS was estimated for two electrodes (anode and cathode). The cyclic voltammograms of the symmetric cell exhibited oxidation and reduction peaks during anodic and cathodic sweeps, respectively, under the scan rate from 20 to 200 mV.s−1 within the voltage window ranging from 0 to 1.5 V, indicating faradaic reaction, Fig. 6a. The galvanostatic charge-discharge profile of the symmetric cell was recorded under the current density ranging from 0.25 to 0.02 A.g−1, Fig. 6b (in semi-log scale). The maximum specific capacity of the CNBS based symmetric device was obtained 101.7 mAh.g−1 at the current density of 0.02 A.g−1. At the current density 0.25 A.g−1, a decrease in specific capacity was noticed with the value of 33.47 mAh.g−1. The trend of specific capacity as a function of current density is represented in Fig. 6c. The figure indicate that specific capacity is inversely proportional with current density. At high current density, the electrolyte ions are unable to transfer charge effectively within the material due to insufficient time, leading to a decrease in specific capacity value. Stability is one of the important parameters in an electrochemical study. The stability of the device needs to be verified before use for long term application. The long term stability of the symmetric device was tested for 500 cycles of galvanostatic charge-discharge process under the constant current density of 0.12 A.g−1. Figure 6c, inset, demonstrates the significant stability of the device and retained 99% of the initial specific capacity value after 500 cycles. Figure 6d exhibited the graphical representation of other electrochemical parameters, such as energy density and power density as a function of current density. At the current density of 0.25 A.g−1, the device exhibited energy density of 24.35 mWh.kg−1 and power density of 186.57 W.kg−1. A comparison data with capacitance and / or capacity values of some reported bismuth sulfide based materials are incorporated in supplementary Table S1.

(a) Cyclic voltammograms of the CNBS-based symmetric cell collected at various scan rates. (b) Galvanostatic charge-discharge profile under the current densities from 0.25A.g−1 to 0.02A.g−1 (in semi-log scale). (c) The graphical representation of specific capacity as a function of current density of the symmetric device (main panel). Galvanostatic charge-discharge cycles (5 × 102) at the current density of 3.0 A.g−1, which retained 99% of the original specific capacitance value of the device (inset). (d) The variation of energy density and power density as a function of current density of the CNBS based symmetric device.

The Nyquist plot of the symmetric device, along with the fitting line (red colour), within the frequency range from 10 mHz to 100 KHz, is shown in Fig. 7a, main panel. The magnified image of the Nyquist plot for the high frequency region is shown in Fig. 7a (I). The Nyquist data of the device is fitted with the equivalent circuit model, Fig. 7a (II), and the fitting parameters are included in supplementary table S2. The device displayed equivalent series resistance (R1) of 1.101 Ω, related to the contact resistance between the active material and electrolyte interface. The equivalent circuit displays the charge transfer resistance (R2) with the value of 191.5 Ω, which validate the occurrence of Faradaic reactions and is parallel to the constant phase element (Q2). The leakage current resistance (R3), with the value of 0.0598 Ω, connected in parallel with the leakage capacitance (Q3). The Warburg-frequency (W) causes the slope to deviate from the imaginary impedance axes in the low-frequency region that hinders ion diffusion to the electrode surface.

A complex capacitance can be modelled based on the real part of the capacitance (C′) and imaginary part of the capacitance (C″), as a function of the frequency, Fig. 7b, and has been used to investigate the frequency behavior of the device. The real capacitance represents the accessible capacitance of the device that can be delivered. The maximum value of the real capacitance (C′) of the device is 53 µF at low frequency. The imaginary component of the capacitance correspond to the energy lost by the electrodes through irreversible processes. The C″ has a peak maximum value of 13.25 µF at 1.223 KHz that corresponds to the charging time (τ) of 130.13 µs obtained by using 2πfτ = 1. This indicate that the device can be fully charged within 130.13 µs. The low τ value demonstrates the high power performances of the device. The mass of the active material strongly affects the τ value.52 The τ corresponds to device charging time and also defining the transition point between resistive and capacitive behaviour of the device.53 This suggests the fabricated device can serve as a capacitor toward low frequency region. These representations can be useful to design the device as a low frequency oscillator.

Application of Supercapacitor as Low Frequency Oscillator

An oscillator is a vital electronic circuit that generates periodic and repetitive waveforms, such as sinusoidal (harmonic oscillator), square or triangular waves (relaxation oscillator). Among the different types of oscillators, low-frequency oscillators (LFOs) are particularly applied in automation systems, engineering circuits and biomedical applications, which operate within the range from a very low frequency to a few hundred Hertz.54,55 In this study, the LFO circuit consists of two operational amplifiers (op-amps), three resistors, R1 (1 kΩ), R2 (1 kΩ), and R3 (10 Ω), and the above mentioned laboratory fabricated CNBS based cion cell supercapacitor, Fig. 8a. The circuit diagram consists of two parts, comparator and integrator. The overall operation of the circuit involves the exchange of energy between the active and passive components (resistor and capacitor) with the frequency of oscillations determined by the charging and discharging time constant. Within the circuit, two signals (voltage as a function of time) are generated at Vout1 and Vout2 nodes. Vout1 represents the output of the comparator circuit in terms of voltage with respect to time that generates a square wave. This square wave is then fed into the integrator section of the circuit, resulting in the generation of a triangular wave as an output, labelled as Vout2. The output waveforms at Vout1 and Vout2 nodes is shown in Fig. 8b. The frequency of these waveforms is 86 Hz, corresponding to a low-frequency range. The designed circuit with the lab made supercapacitor can generate the low frequency waveform for various electronics applications.

Conclusion

Carbon nitride supported bismuth sulfide nanoparticles, synthesized by applying an in-situ synthesis route, has been employed as an electrode material for supercapacitor application. The orthorhombic crystal structure of bismuth sulfide particles within the size range of 15–30 nm were dispersed on the carbon nitride network. The cyclic voltammograms of the CNBS modified electrode, for three electrode system, demonstrated pseudo-redox reaction occurred on the electrode surface. The galvanostatic charge-discharge measurement was conducted within the current densities from 4.0 A.g−1 to 1.5 A.g−1 and maximum specific capacitance value 190 F.g−1 was obtained under the current density of 1.5 A.g−1. The CNBS modified electrode demonstrated good stability and retained 90% of its original specific capacitance value after 1000 cycles during galvanostatic charge-discharge experiments at the current density of 3 A.g−1. At the current density of 1.5 A.g−1, the energy density and power density values are found to be 23.56 Wh.kg−1 and 557.38 W.kg−1, respectively. The BSCN based symmetric device displayed the maximum specific capacity value of 101.7 mAh.g−1 at the current density of 0.02 A.g−1. The symmetric device was highly stable as it retained 99% of its original specific capacity value, after 500 cycles, at the current density of 0.12 A.g−1. The device exhibited energy and power densities of 24.35 mWh.kg−1 and 186.57 W.kg−1, respectively, at the current density of 0.25 A.g−1. The fabricated symmetric supercapacitor has the ability to act as a low frequency oscillator and could have the potential for various electronics applications.

References

I. Lisiecki, Size, shape, and structural control of metallic nanocrystals. J. Phys. Chem. B 109, 12231–12244 (2005).

V.K. Perla, S.K. Ghosh and K. Mallick, Ultrafine nickel sulfide-based bipolar resistive switching device as artificial synapses for neuromorphic application. ACS Appl. Electron. Mater. 4, 6117–6124 (2022).

L. Qingzhuo, S. Liang, J. Wang, R. Zhang and X. Wang, Cadmium sulfide 3D photonic crystal with hierarchically ordered macropores for highly efficient photocatalytic hydrogen generation. Inorg. Chem. 61, 2920–2928 (2022).

K. Waszkowska, O. Krupka, O. Kharchenko, V. Figà, V. Smokal, N. Kutsevol and B. Sahraoui, Influence of ZnO nanoparticles on nonlinear optical properties. Appl. Nanosci. 10, 4977–4982 (2020).

A.H. Jaafar, C. Lowe, A. Gee and N.T. Kemp, Optoelectronic switching memory based on ZnO nanoparticle/polymer nanocomposites. ACS Appl. Polym. Mater. 5, 2367–2373 (2023).

Q. Wang, B. Wang, D. Shi, F. Li and D. Ling, Cerium oxide nanoparticles-based optical biosensors for biomedical applications. Adv. Sensor Res. 2, 2200065 (2023).

O. Cheng, D.H. Son and M. Sheldon, Light-induced magnetism in plasmonic gold nanoparticles. Nat. Photonics 14, 365–368 (2020).

S.K. Ghosh, V.K. Perla, H. Singh and K. Mallick, Dielectric capacitance and energy storage performances of organic molecule stabilized hexagonal lead iodide with a layered network. FlatChem. 37, 100457 (2023).

G. Zhang, S. Wei and A.M. Belcher, Biotemplated zinc sulfide nanofibers as anode materials for sodium-ion batteries. ACS Appl. Nano Mater. 1, 5631–5639 (2018).

R. Nielsen, T. Youngman, A. Crovetto, O. Hansen, I. Chorkendorff and P. Vesborg, Selenium thin-film solar cells with cadmium sulfide as a heterojunction partner. ACS Appl. Energy Mater. 4, 10697–10702 (2021).

M. Chauhan, K.P. Reddy, C.S. Gopinath and S. Deka, Copper cobalt sulfide nanosheets realizing a promising electrocatalytic oxygen evolution reaction. ACS Catal. 7, 5871–5879 (2017).

M. Silva, C. Leite, M. Cordeiro, V. Mastelaro and E. Leite, One-step synthesis of nickel sulfides and their electrocatalytic activities for hydrogen evolution reaction: a case study of crystalline h-NiS and o-Ni9S8 nanoparticles. ACS Appl. Energy Mater. 3, 9498–9503 (2020).

Q. Tang, Q. Jiang, W. Tao, T. Wu, Z. Ding, J. Wu, H. Yu and K. Huang, Binary iron sulfide as a low-cost and high-performance anode for lithium-/sodium-ion batteries. ACS Appl. Mater. Interfaces 12, 52888–52898 (2020).

A.K. Sahu, A. Asokan and G. Peera, Self-assembled manganese sulfide nanostructures on graphene as oxygen reduction catalyst for anion exchange membrane fuel cells. ChemElectroChem 4, 1544 (2017).

Y. Shan, Y. Li and H. Pang, Applications of tin sulfide-based materials in lithium-ion batteries and sodium-ion batteries. Adv. Funct. Mater. 30, 2001298 (2020).

K. Ramasamy, R.K. Gupta, H. Sims, S. Palchoudhury, S. Ivanov and A. Gupta, Layered ternary sulfide CuSbS2 nanoplates for flexible solid-state supercapacitors. J. Mater. Chem. A. 3, 13263–13274 (2015).

N. Devi, S. Ghosh and K. Mallick, Supercapacitive performance of highly dispersed bismuth sulfide nanoparticles in organic matrix: the role of sulphur source. Inorg. Chem. Commun. 103, 93–99 (2019).

S.-J. Liu, Y.-F. Hou, S.-L. Zheng, Y. Zhang and Y. Wang, One-dimensional hierarchical Bi2WO6 hollow tubes with porous walls: synthesis and photocatalytic property. CrystEngComm 15, 4124–4130 (2013).

S. Chakraborty and M. Pal, Highly efficient novel carbon monoxide gas sensor based on bismuth ferrite nanoparticles for environmental monitoring. New J. Chem. 42, 7188–7196 (2018).

J.K. Cooper, S. Gul, F.M. Toma, L. Chen, Y.-S. Liu, J. Guo, J.W. Ager, J. Yano and I.D. Sharp, Indirect bandgap and optical properties of monoclinic bismuth vanadate. J. Phys. Chem. C 119, 2969–2974 (2015).

N. Devi, S.K. Ghosh, V.K. Perla and K. Mallick, Organic–inorganic complexation chemistry-mediated synthesis of bismuth–manganese bimetallic oxide for energy storage application. ACS Omega 5, 18693–18699 (2020).

S.K. Ghosh, V.K. Perla and K. Mallick, Oxygen vacancy-controlled dielectric relaxation and field-driven polarization of bismuth–manganese bimetallic oxide nanoparticles: implications for capacitors. ACS Appl. Nano Mater. 4, 7116–7124 (2021).

B. Sarma, A.L. Jurovitzki, Y.R. Smith, S.K. Mohanty and M. Misra, Redox-induced enhancement in interfacial capacitance of the titania nanotube/bismuth oxide composite electrode. ACS Appl. Mater. Interfaces 5, 1688–1697 (2013).

H.-W. Wang, Z.-A. Hu, Y.-Q. Chang, Y.-L. Chen, Z.-Q. Lei, Z.-Y. Zhang and Y.-Y. Yang, Facile solvothermal synthesis of a graphene nanosheet–bismuth oxide composite and its electrochemical characteristics. Electrochim. Acta 55, 8974–8980 (2010).

C. Largeot, C. Portet, J. Chmiola, P.-L. Taberna, Y. Gogotsi and P. Simon, Relation between the Ion size and pore size for an electric double-layer capacitor. J. Am. Chem. Soc. 130, 2730–2731 (2008).

V.D. Nithya, R. Kalai Selvan, D. Kalpana, L. Vasylechko and C. Sanjeeviraja, Synthesis of Bi2WO6 nanoparticles and its electrochemical properties in different electrolytes for pseudocapacitor electrodes. Electrochim. Acta 109, 720–731 (2013).

V.V. Jadhav, M.K. Zate, S. Liu, M. Naushad, R.S. Mane, K.N. Hui and S.-H. Han, Mixed-phase bismuth ferrite nanoflake electrodes for supercapacitor application. Appl. Nanosci. 6, 511–519 (2016).

J. Sun, J. Wang, Z. Li, Z. Yang and S. Yang, Controllable synthesis of 3D hierarchical bismuth compounds with good electrochemical performance for advanced energy storage devices. RSC Adv. 5, 51773–51778 (2015).

T. Selvamani, B.G.S. Raj, S. Anandan, J.J. Wu and M. Ashokkumar, Synthesis of morphology-controlled bismutite for selective applications. Phys. Chem. Chem. Phys. 18(11), 7768–7779 (2016).

A.A. Ensafi, N. Ahmadi and B. Rezaei, Electrochemical preparation of CuBi2O4 nanoparticles on nanoporous stainless steel as a binder-free supercapacitor electrode. J. Alloys Compd. 652, 39–47 (2015).

Z.-Q. Liu, L.-Y. Tang, N. Li, K. Xiao, J. Wang, J.-H. Zhang, Y.-Z. Su and Y. Tong, Facile synthesis of large-area hierarchical bismuth molybdate nanowires for supercapacitor applications. J. Electrochem. Soc. 159, D582–D586 (2012).

N. Devi, S. Ghosh, S. Ray and K. Mallick, Organic matrix stabilized ultra-fine bismuth oxide particles for electrochemical energy storage application. ChemistrySelect 3, 12057–12064 (2018).

H. Nosrati, J. Charmi, M. Salehiabar, F. Abhari and H. Danafar, Tumor targeted albumin coated bismuth sulfide nanoparticles (Bi2S3) as radiosensitizers and carriers of curcumin for enhanced chemoradiation therapy. ACS Biomater. Sci. Eng. 5, 4416–4424 (2019).

L. Martinez, A. Stavrinadis, S. Higuchi, S.L. Diedenhofen, M. Bernechea, K. Tajima and G. Konstantatos, Hybrid solution-processed bulk heterojunction solar cells based on bismuth sulfide nanocrystals. Phys. Chem. Chem. Phys. 15, 5482–5487 (2013).

W. Xu, J. Fang, Y. Chen, S. Lu, G. Zhou, X. Zhu and Z. Fang, Novel heterostructured Bi2S3/Bi2Sn2O7 with highly visible light photocatalytic activity for the removal of Rhodamine B. Mater. Chem. Phys. 154, 30–37 (2015).

H. Kan, M. Li, Z. Song, S. Liu, B. Zhang, J. Liu, M.Y. Li, G. Zhang, S. Jiang and H. Liu, Highly sensitive response of solution-processed bismuth sulfide nanobelts for room-temperature nitrogen dioxide detection. J. Colloid Interface Sci. 506, 102–110 (2017).

X. Jiang, Y. Song, M. Dou, J. Ji and F. Wang, Selective growth of vertically aligned two-dimensional MoS2/WS2 nanosheets with decoration of Bi2S3 nanorods by microwave-assisted hydrothermal synthesis: enhanced photo-and electrochemical performance for hydrogen evolution reaction. Int. J. Hydrog. Energy 43, 21290–21298 (2018).

Q. Wang, X. Wang, W. Lou and J. Hao, Ionothermal synthesis of bismuth sulfide nanostructures and their electrochemical hydrogen storage behavior. New J. Chem. 34, 1930–1935 (2010).

D. Guo, C. Hu and C. Zhang, First-principles study on doping and temperature dependence of thermoelectric property of Bi2S3 thermoelectric material. Mater. Res. Bull. 48, 1984–1988 (2013).

Y. Zhao, L. Ma, Y. Zhu, P. Qin, H. Li, F. Mo, D. Wang, G. Liang, Q. Yang, W. Liu and C. Zhi, Inhibiting grain pulverization and sulfur dissolution of bismuth sulfide by ionic liquid enhanced Poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) for high-performance zinc-ion batteries. ACS Nano 13, 7270–7280 (2019).

E. Miniach and G. Gryglewicz, Solvent-controlled morphology of bismuth sulfide for supercapacitor applications. J. Mater. Sci. 53, 16511–16523 (2018).

T. Alizadeh, S. Nayeri and N. Hamidi, Graphitic carbon nitride (g-C3N4)/graphite nanocomposite as an extraordinarily sensitive sensor for sub-micromolar detection of oxalic acid in biological samples. RSC Adv. 9, 13096–13103 (2019).

L. Zhang, P. Ghimire, J. Phuriragpitikhon, B. Jiang, A.A.S. Gonçalves and M. Jaroniec, Facile formation of metallic bismuth/bismuth oxide heterojunction on porous carbon with enhanced photocatalytic activity. J. Colloid Interface Sci. 513, 82–91 (2018).

S. Wang, W. Li, H. Song, C. Mao, Z. Zhang, H. Peng and G. Li, Nitrogen-enriched carbon-coated flower-like bismuth sulfide architectures towards high-performance lithium-ion battery anodes. Inorg. Chem. Front. 6, 1275–1281 (2019).

X. Wang, C. Zhou, R. Shi, Q. Liu, G.I.N. Waterhouse, L. Wu, C.-H. Tung and T. Zhang, Supramolecular precursor strategy for the synthesis of holey graphitic carbon nitride nanotubes with enhanced photocatalytic hydrogen evolution performance. Nano Res. 12, 2385–2389 (2019).

L. Tan, J. Xu, X. Zhang, Z. Hang, Y. Jia and S. Wang, Synthesis of g-C3N4/CeO2 nanocomposites with improved catalytic activity on the thermal decomposition of ammonium perchlorate. Appl. Surf. Sci. 356, 447–453 (2015).

G. Nie, X. Lu, J. Lei, L. Yang and C. Wang, Facile and controlled synthesis of bismuth sulfide nanorods-reduced graphene oxide composites with enhanced supercapacitor performance. Electrochim. Acta 154, 24–30 (2015).

J. Yan, Z. Fan, W. Sun, G. Ning, T. Wei, Q. Zhang, R. Zhang, L. Zhi and F. Wei, Advanced asymmetric supercapacitors based on Ni(OH)2/graphene and porous graphene electrodes with high energy density. Adv. Funct. Mater. 22, 2632–2641 (2012).

Y.-K. Hsu, Y.-C. Chen and Y.-G. Lin, Synthesis of copper sulfide nanowire arrays for high-performance supercapacitors. Electrochim. Acta 139, 401–407 (2014).

H.S. Kim, J.B. Cook, H. Lin, J.S. Ko, S.H. Tolbert, V. Ozolins and B. Dunn, Oxygen vacancies enhance pseudocapacitive charge storage properties of MoO3-x. Nat. Mater. 16, 454–460 (2017).

V. Augustyn, J. Come, M.A. Lowe, J.W. Kim, P.L. Taberna, S.H. Tolbert, H.D. Abruña, P. Simon and B. Dunn, High-rate electrochemical energy storage through Li+ intercalation pseudocapacitance. Nat. Mater. 12, 518–522 (2013).

P.-C. Gao, W.-Y. Tsai, B. Daffos, P.-L. Taberna, C.R. Pérez, Y. Gogotsi, P. Simon and F. Favier, Graphene-like carbide derived carbon for high-power supercapacitors. Nano Energy 12, 197–206 (2015).

P. Taberna, P. Simon and J. Fauvarque, Electrochemical characteristics and impedance spectroscopy studies of carbon-carbon supercapacitors. J. Electrochem. Soc. 150, A292–A300 (2003).

C. Hwang, S.B. Bibyk, M. Ismail and B. Lohiser, A very low frequency, micropower, low voltage CMOS oscillator for noncardiac pacemakers. IEEE Trans. Circuits Syst. I Regul. Pap. 42, 962–966 (1995).

M. Wang, Very low frequency tunable signal generator for neural and cardiac cell stimulation. Int. J. Electron. 98, 1215–1227 (2011).

Funding

Open access funding provided by University of Johannesburg. This study was financially supported by the Faculty of Science, University Research Council and the Global Excellence and Stature program 4.0, University of Johannesburg.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kumari, P., Perla, V.K., Ghosh, S.K. et al. Carbon Nitride Supported Ultra-fine Bismuth Sulfide Based Supercapacitor for Low Frequency Oscillator Application. J. Electron. Mater. 53, 1498–1507 (2024). https://doi.org/10.1007/s11664-023-10901-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10901-0