Abstract

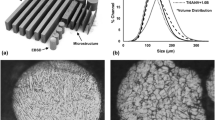

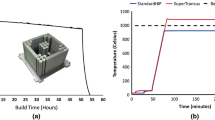

Electron beam melting (EBM) additive manufacturing of Ti–6Al–4V subjects the material to complex thermal cycles, resulting in a columnar morphology of the prior \(\beta \) grains (PBGs). While the columnar PBGs of EBM-processed Ti–6Al–4V can be transformed to an equiaxed morphology through a super-transus (i.e., above the \(\beta \)-transus temperature) heat treatment, this also leads to the formation of a coarse lamellar two-phase microstructure. Such a microstructure is prone to strain localization and premature fracture. Herein, we present a thermohydrogen post-process treatment that achieves equiaxed PBG morphology in EBM-processed Ti–6Al–4V without sacrificing mechanical properties. Our results show that a three-step thermohydrogen post-process treatment can transform the columnar PBG morphology to an equiaxed morphology with fine microstructure, and strength and ductility levels comparable to those of the most optimum as-fabricated samples. This three-step thermohydrogen post-process treatment involves hydrogenation and phase transformation treatment in a hydrogen atmosphere, and subsequent dehydrogenation treatment in vacuum. Notably, all these treatments are carried out at temperatures well below the \(\beta \)-transus temperature of hydrogen-free Ti–6Al–4V.

Similar content being viewed by others

References

L.E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, K.N. Amato, P.W. Shindo, F.R. Medina, and R.B. Wicker: J. Mater. Sci. Technol., 2012, vol. 28, pp. 1–4.

W.E. Frazier: J. Mater. Eng. Perform., 2014, vol. 23, pp. 1917–28.

S. Liu and Y.C. Shin: Mater. Des., 2019, vol. 164, p. 107552.

L. Facchini, E. Magalini, P. Robotti, and A. Molinari: Rapid Prototyp. J., 2009, vol. 15, pp. 171–78.

S.S. Al-Bermani, M.L. Blackmore, W. Zhang, and I. Todd: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 3422–34.

A.A. Antonysamy, J. Meyer, and P.B. Prangnell: Mater Charact, 2013, vol. 84, pp. 153–68.

C. De Formanoir, S. Michotte, O. Rigo, L. Germain, and S. Godet: Mater. Sci. Eng. A, 2016, vol. 652, pp. 105–19.

Y. Kok, X.P. Tan, P. Wang, M.L.S. Nai, N.H. Loh, E. Liu, and S.B. Tor: Mater. Des., 2018, vol. 139, pp. 565–86.

H.K. Rafi, N.V. Karthik, H. Gong, T.L. Starr, and B.E. Stucker: J. Mater. Eng. Perform., 2013, vol. 22, pp. 3872–83.

Z. Liu, B. He, T. Lyu, and Y. Zou: JOM, 2021, vol. 73, pp. 1804–18.

G. Lütjering and J.C. Williams: Titanium, 2nd ed. Springer, Berlin, 2007.

P. Nandwana, Y. Lee, C. Ranger, A.D. Rollett, R.R. Dehoff, and S.S. Babu: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 3429–39.

M. Fang, F. Hu, Y. Han, J. Le, J. Xi, J. Song, L. Ke, M. Xiao, and W. Lu: Mater. Sci. Eng. A, 2021, vol. 827, 142031.

M. Seifi, A. Salem, D. Satko, J. Shaffer, and J.J. Lewandowski: Int. J. Fatigue, 2017, vol. 94, pp. 263–87.

H. Gong, K. Rafi, H. Gu, G.D. Janaki Ram, T. Starr, and B. Stucker: Mater. Des., 2015, vol. 86, pp. 545–54.

T. Montalbano, B.N. Briggs, J.L. Waterman, S. Nimer, C. Peitsch, J. Sopcisak, D. Trigg, and S. Storck: J. Mater. Process. Technol., 2021, vol. 294, 117113.

S.P. Narra, A.D. Rollett, A. Ngo, D. Scannapieco, M. Shahabi, T. Reddy, J. Pauza, H. Taylor, C. Gobert, and E. Diewald: J. Mater. Process. Technol., 2022, vol. 311, p. 117775.

R. Cunningham, A. Nicolas, J. Madsen, E. Fodran, E. Anagnostou, M.D. Sangid, and A.D. Rollett: Mater. Res. Lett., 2017, vol. 5, pp. 516–25.

H. Galarraga, R.J. Warren, D.A. Lados, R.R. Dehoff, M.M. Kirka, and P. Nandwana: Mater. Sci. Eng. A, 2017, vol. 685, pp. 417–28.

L. Draelos, P. Nandwana, and A. Srivastava: Mater. Sci. Eng. A, 2020, vol. 795, p. 139986.

Y. Zhou, K. Wang, Z. Sun, and R. Xin: J. Mater. Process. Technol., 2022, vol. 306, 117607.

J. Liu, G. Li, Q. Sun, H. Li, J. Sun, and X. Wang: J. Mater. Process. Technol., 2022, vol. 299, 117366.

M. Jamshidinia, M.M. Atabaki, M. Zahiri, S. Kelly, A. Sadek, and R. Kovacevic: J. Mater. Process. Technol., 2015, vol. 226, pp. 264–71.

M.J. Bermingham, D. Kent, H. Zhan, D.H. Stjohn, and M.S. Dargusch: Acta Mater., 2015, vol. 91, pp. 289–303.

O.N. Senkov and F.H. Froes: Int. J. Hydrogen Energy, 1999, vol. 24, pp. 565–76.

D.H. Kohn and P. Ducheyne: J. Mater. Sci., 1991, vol. 26, pp. 328–34.

M. Niinomi, B. Gong, T. Kobayashi, Y. Ohyabu, and O. Toriyama: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 1141–51.

F.H. Froes, O.N. Senkov, and J.I. Qazi: Int. Mater. Rev., 2004, vol. 49, pp. 227–45.

Z. Sun, W. Zhou, and H. Hou: Int. J. Hydrogen Energy, 2009, vol. 34, pp. 1971–76.

J.D. Paramore, Z.Z. Fang, P. Sun, M. Koopman, K.S.R. Chandran, and M. Dunstan: Scripta Mater., 2015, vol. 107, pp. 103–06.

J.D. Paramore, Z.Z. Fang, M. Dunstan, P. Sun, and B.G. Butler: Sci. Rep., 2017, vol. 7, p. 41444.

M. Knezevic, S. Ghorbanpour, N.C. Ferreri, I.A. Riyad, A.D. Kudzal, J.D. Paramore, S.C. Vogel, and B.A. Mcwilliams: Mater. Sci. Eng. A, 2021, vol. 809, 140980.

H. Galarraga, D.A. Lados, R.R. Dehoff, M.M. Kirka, and P. Nandwana: Addit. Manuf., 2016, vol. 10, pp. 47–57.

ASTM E1447-09: Standard Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by Inert Gas Fusion Thermal Conductivity/Infrared Detection Method, ASTM International, Materials Park, 2016.

ASTM E8/E8M-21: Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, Materials Park, 2021.

ASTM B348-10: Standard Specification for Titanium and Titanium Alloy Bars and Billets, ASTM International, Materials Park, 2010.

ASTM E112-13: Standard Test Methods for Determining Average Grain Size, ASTM International, Materials Park, 2021.

G.C. Obasi, S. Birosca, J.Q. Da Fonseca, and M. Preuss: Acta Mater., 2012, vol. 60, pp. 1048–58.

P. Sun, Z.Z. Fang, M. Koopman, J. Paramore, K.R. Chandran, Y. Ren, and J. Lu: Acta Mater., 2015, vol. 84, pp. 29–41.

P. Sun, Z.Z. Fang, M. Koopman, Y. Xia, J. Paramore, K. Ravi Chandran, Y. Ren, and J. Lu: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 5546–60.

Acknowledgments

LDH is thankful to Michael Taylor Hurst and Daniel Oliver Lewis of Texas A&M University for their technical assistance with the hydrogenation experiments. AS gratefully acknowledges the financial support provide by the Haythornthwaite Foundation through the ASME/AMD – Haythornthwaite Research Initiation Grant, the US Army Research Laboratory through the cooperative agreement - Materials and Manufacturing Processes for the Army of the Future, and the U.S. National Science Foundation Grant CMMI-1944496.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

James D. Paramore, and Brady G. Butler have patent #Thermo-hydrogen refinement of microstructure of titanium materials (US10920307B2) issued to University of Utah Research Foundation; US Department of Army.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Draelos-Hagerty, L., Paramore, J.D., Butler, B.G. et al. Hydrogen-Aided Microstructural Engineering of Additively Manufactured Ti–6Al–4V. Metall Mater Trans B 54, 3451–3461 (2023). https://doi.org/10.1007/s11663-023-02924-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02924-z