Abstract

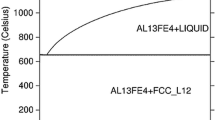

The hydrogen sintering and phase transformation (HSPT) process is a novel powder metallurgy method for producing Ti alloys, particularly the Ti-6Al-4V alloy, with ultra-fine microstructure in the as-sintered state. The ultra-fine microstructure is obtained as a direct result of the use of H2 gas during sintering. The refinement of the microstructure during HSPT is similar to that of thermal hydrogen processing (THP) of bulk Ti alloys. For both THP and HSPT of Ti-6Al-4V alloy, the mechanisms of the grain refinement depend on the phase equilibria and phase transformations in the presence of hydrogen, which are surprisingly still not well established to date and are still subjected to research and debate. In recent work by the present authors, a pseudo-binary phase diagram of (Ti-6Al-4V)-H has been determined by using in situ synchrotron XRD and TGA/DSC techniques. Aided by this phase diagram, the current paper focuses on the series of phase transformations during sintering and cooling of Ti-6Al-4V in a hydrogen atmosphere and the mechanisms for the formation of the ultra-fine microstructures obtained. Using experimental techniques, including in situ synchrotron XRD, SEM, EBSD, and TEM, the microstructural refinement was found to be the result of (1) the precipitation of ultra-fine α/α2 within coarse β grains during an isothermal hold at intermediate temperatures, and (2) the eutectoid transformation of β → α + δ at approximately 473 K (200 °C).

Similar content being viewed by others

References

Z.Z. Fang, P. Sun and H. Wang, Adv. Eng. Mater., 2012, vol. 14, pp. 383-387.

P. Sun, Z.Z. Fang and M. Koopman, Adv. Eng. Mater., 2013, vol. 15, pp. 1007-1013.

J.D. Paramore, Z.Z. Fang, P. Sun, M. Koopman, K.S.R. Chandran and M. Dunstan, Scripta Mater., 2015, 107, 103-106.

Z.Z. Fang and S. Pei, Key Eng. Mater., 2012, vol. 520, pp. 15-23.

P. Sun, Z.Z. Fang, M. Koopman, J. Paramore, K.S.R. Chandran, Y. Ren and J. Lu, Acta Mater., 2015, vol. 84, pp. 29-41.

J. Greenspan, F.J. Rizzitano, and E. Scala: Titanium Science and Technology: Proceedings of the Second International Conference, Plenum Press, Cambridge, Massachusetts, 1973, pp. 365–79.

O.M. Ivasishin, V.M. Anokhin, A.N. Demidik, and D.G. Savvakin: Development in Light Metals -Science, Technology and Applications International Conference, 19–24 Sept. 1999, Trans Tech Publications, Switzerland, 2000, pp. 55–62.

O.M. Ivasishin, D.G. Savvakin, F. Froes, V.C. Mokson and K.A. Bondareva, Powder Metall. Met. Ceram., 2002, vol. 41, pp. 382-90.

O.M. Ivasishin, K.A. Bondareva, V.I. Bondarchuk, O.N. Gerasimchuk, D.G. Savvakin and B.A. Gryaznov, Strength Mater., 2004, vol. 36, pp. 225-230.

S.D. Luo, Y.F. Yang, G.B. Schaffer and M. Qian, Scripta Mater., 2013, vol. 69, pp. 69-72.

F.H. Froes, O.N. Senkov and J.I. Qazi, Inter. Mater. Rev., 2004, vol. 49, pp. 227-245.

U. Zwicker and W.S. Hans: U.S. Patent 2892742 A, 1959.

W.R. Kerr, P.R. Smith, M.E. Rosenblum, F.J. Gurney, Y.R. Mahajan, and L.R. Bidwell: Titanium ‘80, Science and Technology, Proceedings of the 4th International Conference on Titanium., Metall Soc of AIME, Kyoto, Japan, 1980, pp. 2477–86.

W.R. Kerr, Metall. Mater. Trans. A, 1985, vol. 16, pp. 1077-1087.

B. Gong, M. Niinomi, T. Kobayashi and Y. Ohyabu, J. Jpn. Inst. Light Met., 1992, vol. 42, pp. 638-43.

A.A. Ilyn, B.A. Kolachev and A.M. Mamonov, In Titanium’92 Science and Technology, San Diego, CA, 1992, Metallurgical Society of AIME, New York, pp 941-947.

C. Zhang, W. Bian, Z. Lai and B. Gong, Acta Metall. Sin. A, 1992, vol. 5, pp. 362-368.

T.Y. Fang and W.H. Wang, Mater. Chem. Phys., 1998, vol. 56, pp. 35-47.

J. Qazi, J. Rahim, F. Fores, O. Senkov and A. Genc, Metall. Mater. Trans. A, 2001, vol. 32, pp. 2453-2463.

C.C. Shen and T.P. Perng, Acta Mater., 2007, vol. 55, pp. 1053-1058.

A.A. Il’in, A.M. Mamonov, and M.U. Kollerov: Russ. Metall., 1994, vol. 1994, pp. 157–68.

M. Qian, Inter. J. Powder Metall., 2010, vol. 46, pp. 29-44.

G. Lütjering, Mater. Sci. Eng. A, 1998, vol. 243, pp. 32-45.

H. Wang, Z.Z. Fang and P. Sun, Inter. J. Powder Metall., 2010, vol. 46, pp. 45-57.

S. Wright and B. Adams, Metall. Trans. A, 1992, vol. 23, pp. 759-767.

A.A. Salem, M.G. Glavicic and S.L. Semiatin, Mater. Sci. Eng. A, 2008, vol. 494, pp. 350-359.

Z. Wu and H. Bei, Mater. Sci. Eng. A, 2015, vol. 640, pp. 217-224.

Z. Wu, C.M. Parish and H. Bei, J Alloy. Compd., 2015, vol. 647, pp. 815-822.

F.D. Manchester and A. San-Martin, In Phase diagrams of binary hydrogen alloys, ASM International: Materials Park, OH, 2000.

M. Yan, M.S. Dargusch, C. Kong, J.A. Kimpton, S. Kohara, M. Brandt and M. Qian, Metall. Mater. Trans. A, 2015, vol. 46, pp. 41-45.

O.M. Ivasishin, D. Eylon, V.I. Bondarchuk and D.G. Savvakin, In Diffusion and Diffusional Phase Transformations in Alloys, Trans Tech Publications Ltd, Switzerland, 2008, pp 177-185.

X. Xu, G. Nash and P. Nash, J. Mater. Sci., 2014, vol. 49, pp. 994-1008.

W.E. Wang, J Alloy. Compd., 1996, vol. 238, pp. 6-12.

G. Lütjering and J.C. Williams: Titanium. Springer, New York, 2003.

F.A. Crossley, Trans. AIME, 1969, vol. 245, pp. 1963-1968.

M. Yan, M.S. Dargusch, T. Ebel and M. Qian, Acta Mater., 2014, vol. 68, pp. 196-206.

C.C. Shen, C.Y. Yu and T.P. Perng, Acta Mater., 2009, vol. 57, pp. 868-874.

M.B. Ivanov, S.S. Manokhin, Y.R. Kolobov and D.A. Nechayenko, Mater. Phys. Mech., 2010, vol. 10, pp. 62-71.

F.H. Froes and H.B. Bomberger, JOM, 1985, vol. 37, pp. 28-37.

A. Lenain, N. Clément, M. Véron and P.J. Jacques, J. Mater. Eng. Perform., 2005, vol. 14, pp. 722-727.

N. Clement, A. Lenain and P.J. Jacques, JOM, 2007, vol. 59, pp. 50-3.

R.F. Boyer and E. Collings: Materials properties handbook: titanium alloys. ASM International, Materials Park, OH, 1994.

Molchanova EK (1965) Phase Diagrams of Titanium Alloys. Jerusalem: Israel Program for Scientific Translations Ltd.

A.A. Ilyin, I.S. Polkin, A.M. Mamonov and V.K. Nosov, In Titanium ‘95: Science and Technology, Institute of materials, London, England, 1996, pp 2462-69.

A.A. Il’in, M.Y. Kollerov, S.V. Skvortsova, A.A. Popov and N.O. Osintseva, Russ. Metall., 2002, vol. 2002, pp. 263-267.

C. Leyens and M. Peters: Titanium and Titanium Alloys. Fundamental and Applications. Wiley-VCH, Weihheim, Germany, 2003.

S.V. Skvortsova, A.A. Ilin, V.V. Zasypkin, G.V. Gurtovaya and E.V. Klubova, Russ. Metall., 2006, vol. 206, pp. 232-238.

Acknowledgments

The authors acknowledge funding support by the U.S. Department of Energy, Innovative Manufacturing Initiative (DEEE0005761), through the Advanced Manufacturing Office and the Office of Energy Efficiency and Renewable Energy. Use of the Advanced Photon Source, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science by Argonne National Laboratory, was supported by the U.S. DOE under Contract No. DE-AC02-06CH11357. The first author acknowledges the valuable assistance of Dr. Xiangyi Luo, Mr. Chun Yu, and Mr. Rick Spence for synchrotron X-ray experiments at Argonne National Lab, and the help of Dr. Paulo Perez and Dr. Matt Nowell for collecting EBSD data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 29, 2014.

Rights and permissions

About this article

Cite this article

Sun, P., Fang, Z.Z., Koopman, M. et al. Phase Transformations and Formation of Ultra-Fine Microstructure During Hydrogen Sintering and Phase Transformation (HSPT) Processing of Ti-6Al-4V. Metall Mater Trans A 46, 5546–5560 (2015). https://doi.org/10.1007/s11661-015-3141-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3141-8