Abstract

Tellurium (Te) modification is an important method to improve the morphology of sulfide (MnS) in steel, the morphology of MnS varies with the difference in Te content of Te-containing inclusions. To explore the relationship between the concentration of Te in Te-containing inclusions and the morphology, 32 and 68 ppm Te were added into medium-carbon microalloyed steel (MCMAS) under laboratory conditions. It shows that the average density and area content of inclusion increase with the increasing Te content in steel, the distribution of inclusions is the most uniform in S2, unlike the aggregation of inclusions in S3. The main types of inclusions include single-particle MnS and telluride (MnTe), as well as their composite inclusions. Different types of composite inclusions can be divided into semi-surround composite (SSC), surround composite (SC), equivalent composite (EC), and ovulatory composite (OC). Combining the observation results, the nucleation kinetics of MnS and MnTe, and the crystallographic analysis of various MnS and MnTe phases, the formation mechanisms of different Te-containing inclusions were discussed.

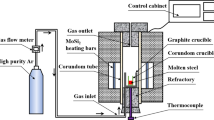

Adapted from Ref. [16], © The Minerals, Metals & Materials Society and ASM International 2022 (Color figure online)

Similar content being viewed by others

References

C. Capdevila, F.G. Caballero, C. García-Mateo, and C.G. De-Andrés: Mater. Trans., 2004, vol. 45, pp. 2678–85.

F. Zhao, H. Hu, X.H. Liu, Z.H. Zhang, and J.X. Xie: J. Alloys Compd., 2021, vol. 869, p. 159326.

L. Ceschini, A. Marconi, C. Martini, A. Morri, and A. Di Schino: Mater. Des., 2013, vol. 45, pp. 171–78.

C.E. Sims: AIME, 1959, vol. 215, pp. 367–93.

C. Hippsley: Acta Metall., 1987, vol. 35, pp. 2399–416.

B. Wen and B. Song: Steel Res. Int., 2012, vol. 83, pp. 61–72.

Y. Kim, H. Kim, M. Kang, K. Rhee, S.Y. Shin, and S. Lee: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 4615–25.

K. Kishi, H. Eda, and Y. Kitsunai: J. Jpn. Soc. Precis. Eng., 1972, vol. 38, pp. 174–81.

Q.K. Yang, P. Shen, D. Zhang, Y.X. Wu, and J.X. Fu: Int. J. Miner. Metall. Mater., 2018, vol. 25, pp. 420–28.

P. Shen, Q.K. Yang, D. Zhang, S.F. Yang, and J.X. Fu: Metals Basel, 2018, vol. 8, p. 639.

N.F. Liu, Q.R. Tian, Z.F. Wang, X.Y. Xu, J.X. Fu: Ironmak. Steelmak., 2023, vol. 50, pp. 1302–10.

N.F. Liu, X.Y. Xu, Z.F. Wang, W.B. Wu, P. Shen, J.X. Fu, and J. Li: J. Mater. Res. Technol., 2023, vol. 24, pp. 2226–38.

K. Tetsuo, A. Shozo, K. Atsuyoshi, and N. Sadayuki: J. Jpn. Foundry Eng. Soc., 1982, vol. 53, pp. 195–202.

S. Zhang, F. Wang, S. Yang, J. Liu, and J. Li: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2284–95.

F. Wang, H. Guo, W. Liu, S.F. Yang, S. Zhang, and J.S. Li: Materials, 2019, vol. 12, p. 1034.

Q. Huang, Y. Ren, Y. Luo, S. Ji, and L.F. Zhang: Metall. Mater. Trans. B, 2023, vol. 54B, pp. 270–81.

L.C. Zheng, A. Malfliet, P. Wollants, B. Blanpain, and M.X. Guo: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2447–58.

P. Shen, H. Zhang, X.Y. Xu, Q.K. Yang, and J.X. Fu: Steel Res. Int., 2021, vol. 92, p. 2100235.

P. Shen, Q.K. Yang, D. Zhang, Y.X. Wu, and J.X. Fu: Steel Res. Int., 2018, vol. 25, pp. 787–95.

J.B. Xie, T. Fan, H. Sun, Z.Q. Zeng, and J.X. Fu: Met. Mater. Int., 2021, vol. 27, pp. 1416–27.

X.Y. Wu, L.P. Wu, J.B. Xie, P. Shen, and J.X. Fu: Metall. Res. Technol., 2020, vol. 117, pp. 107.

F.B. Pickering: AISI, 1989, pp. 381-401.

Manganese Telluride, 2023, https://www.chembk.com/cn/chem/%E7%A2%B2%E5%8C%96%E9%94%B0

T.Y. T’ien, L.H. Van Vlack, and R.J. Martin: The System MnTe–MnS: Progress Report, The University of Michigan, New York, 1967, pp. 1–8.

H. Suito and H. Ohta: ISIJ Int., 2006, vol. 46, pp. 33–41.

K. Oikawa, K. Ishida, and T. Nishizawa: ISIJ Int., 1997, vol. 37, pp. 332–38.

W.Q. Yang, X.H. Zhu, Z.R. Wei, D.Y. Yang, and L.Z. Li: Mol. Phys., 2011, vol. 109, pp. 251–56.

O. Goede, W. Heimbrod, V. Weinhold, E. Schnürer, and H.G. Eberle: Phys. Status Solidi B, 1987, vol. 143, pp. 511–18.

O. Kavcı and S. Cabuk: Comp. Mater. Sci., 2014, vol. 95, pp. 99–105.

R.W.G. Wyckoff: Crystal Structures, 2nd ed. Interscience, New York, 1963, p. 17.

B.S. Wang and Y. Liu: Acta Phys. Sin., 2016, vol. 65, pp. 246–51.

C.H. Griffiths: J. Mater. Sci., 1978, vol. 13, pp. 513–18.

Acknowledgments

The authors gratefully express their appreciation to Natural Science Foundation of China (Grant No. 52074179) for supporting this work. One of the authors, Xiangyu Xu, gratefully acknowledges support from the National Natural Science Foundation of China (Youth Program No. 52104335) and Shanghai “Super Postdoctoral” Incentive Plan (Grant No. 2020194). Nianfu Liu and Jianxun Fu appreciate the foundation’s support of Major Science and Technology Special Projects in Guangdong Province (Grant No. 220814196271010).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tian, Q., Wang, Z., Zhang, X. et al. Formation Mechanism of Different Morphologies Inclusions in Tellurium-Containing Medium-Carbon-Microalloyed Steel. Metall Mater Trans B 54, 3405–3415 (2023). https://doi.org/10.1007/s11663-023-02917-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02917-y