Abstract

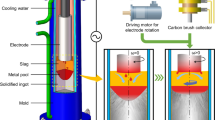

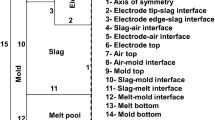

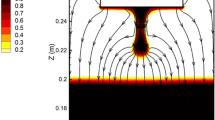

A transient two-dimensional (2D) coupled mathematical model was developed to study the effect of external axial static magnetic field (ASMF) on the evolution of metal pool profiles. Electromagnetic flow, heat transfer, and solidification were explored simultaneously in this model. The growth of the ingot was predicted with the dynamic mesh technique. The calculated results indicated that the temperature distribution became more uniform both in slag and metal pool with 0.05-T ASMF. To characterize the metal pool profile more reasonable, the actual depth \(({H}_{\text{a}}={H}_{\text{m}}-{H}_{\text{c}})\) is defined to represent the depth of the metal pool. Compared with the case without applying ASMF, the calculated actual metal pool profile was flattened remarkably from 23 to 17.5 mm. Meanwhile, the calculated actual metal pool depth was compared with the measurement, which was from 25.5 to 16 mm, in experiments on a laboratory scale to validate the model. In addition, the mechanisms how ASMF improved the metal pool profile were elaborated thoroughly. Under the interaction of ASMF and the direct current component (DCC), the induced rotating Lorentz force makes the temperature field of slag pool more uniform. As a result, the heat transfer from slag to metal pool becomes more well distributed. On the other hand, the forced flow of metal pool by the drag of slag pool can enhance the effective thermal conductivity of metal pool and then reduce the temperature gradient in radial direction. All of above ultimately lead to a shallower metal pool.

Similar content being viewed by others

Abbreviations

- \({A}_{\text{mush}}\) :

-

Mushy zone constant

- B 0 :

-

Applied axial static magnetic flux density (T)

- C p :

-

Heat capacity [J/(kg K)]

- \({C}_{1\varepsilon }\) :

-

1.42

- \({C}_{2\varepsilon }\) :

-

1.68

- \({C}_{3\varepsilon }\) :

-

0.09

- \({C}_{\mu }\) :

-

0.0845

- \(\overrightarrow{{F}_{\text{L}}}\) :

-

Lorentz force (N/m3)

- F Lr :

-

Lorentz force in radial direction (N/m3)

- F Lz :

-

Lorentz force in axial direction (N/m3)

- F Lθ :

-

Lorentz force in azimuthal direction (N/m3)

- \(\overrightarrow{{F}_{\text{p}}}\) :

-

Pressure drop (m/s)

- \({f}_{\text{l}}\) :

-

Liquid fraction

- \(\overrightarrow{g}\) :

-

Gravitational acceleration (m2/s)

- \({G}_{\text{k}}\) :

-

Generation of turbulence kinetic energy due to the mean velocity gradients (Pa·s)

- \({G}_{\text{b}}\) :

-

Generation of turbulence kinetic energy due to buoyancy (Pa·s)

- h :

-

Sensible enthalpy (J/kg)

- \({h}_{\text{ref}}\) :

-

Reference sensible enthalpy (J/kg)

- \({h}_{0}\) :

-

Equivalent heat transfer coefficient on the mold wall [W/(m2·K)]

- \({h}_{\text{r}}\) :

-

Radiation heat transfer coefficient for air gap [W/(m2·K)]

- \({h}_{\text{c}}\) :

-

Convection heat transfer coefficient for air gap [W/(m2·K)]

- \({h}_{\text{w}}\) :

-

Overall heat transfer coefficient between the mold surface and the cooling water [W/(m2·K)]

- H :

-

Enthalpy (J/kg)

- \(\overrightarrow{H}\) :

-

Magnetic field intensity (A/m)

- \({H}_{\theta }\) :

-

Azimuthal component of \(\overrightarrow{H}\) (A/m)

- \({\widehat{H}}_{\theta }\) :

-

Complex amplitude (A/m)

- \({\widehat{H}}_{\theta ,Re}\) :

-

Real part of \({\widehat{H}}_{\theta }\) (A/m)

- \({\widehat{H}}_{\theta ,Im}\) :

-

Imaginary part of \({\widehat{H}}_{\theta }\) (A/m)

- I :

-

Current (A)

- J DC :

-

Direct current density component (A/m2)

- \({\widehat{J}}_{\text{r}}\) :

-

Complex amplitude of current density in radial direction (A/m2)

- \({\widehat{J}}_{\text{r},\text{Re}}\) :

-

Real part of \({\widehat{J}}_{\text{r}}\) (A/m2)

- \({\widehat{J}}_{\text{r},\text{Im}}\) :

-

Imaginary part of \({\widehat{J}}_{\text{r}}\) (A/m2)

- \({\widehat{J}}_{\text{z}}\) :

-

Complex amplitude of current density in axial direction (A/m2)

- \({\widehat{J}}_{\text{z},\text{Re}}\) :

-

Real part of \({\widehat{J}}_{\text{z}}\) (A/m2)

- \({\widehat{J}}_{\text{z},\text{Im}}\) :

-

Imaginary part of \({\widehat{J}}_{\text{z}}\) (A/m2)

- \(k\) :

-

Turbulent kinetic energy (m2/s3)

- \({k}_{\text{eff}}\) :

-

Effective thermal conductivity [W/(m·K)]

- \({k}_{\text{s}}\) :

-

Slag thermal conductivity [W/(m·K)]

- L :

-

Latent heat (J/kg)

- \({Q}_{\text{j}}\) :

-

Joule heating (W/m3)

- P :

-

Pressure (Pa)

- r:

-

Radial coordinate

- \({R}_{\text{contact}}\) :

-

Contact thermal resistance [(m2·K)/W]

- \({R}_{\varepsilon }\) :

-

Additional term of dissipation rate of turbulent kinetic energy (m2/s3)

- \({S}_{\text{k}}\) :

-

Source term of solidification in the turbulent kinetic energy equation (m2/s3)

- \({S}_{\varepsilon }\) :

-

Source term of solidification in the dissipation rate of turbulent kinetic energy equation (m2/s3)

- t :

-

Times (s)

- T :

-

Temperature (K)

- \({T}_{\text{ref}}\) :

-

Reference temperature (K)

- \({T}_{\text{sol}}\) :

-

Solidus temperature (K)

- \({T}_{\text{liq}}\) :

-

Liquidus temperature (K)

- \(\overrightarrow{u}\) :

-

Velocity (m/s)

- \({\overrightarrow{u}}_{\text{cast}}\) :

-

Casting velocity (m/s)

- \({Y}_{\text{M}}\) :

-

Contribution of the fluctuating dilatation to the overall dissipation rate (m2/s3)

- z:

-

Axial coordinate

- \(\alpha \) :

-

Volume of fluid

- \({\alpha }_{\text{k}}\) :

-

Inverse effective Prandtl number for turbulent kinetic energy

- \({\alpha }_{\varepsilon }\) :

-

Inverse effective Prandtl number for dissipation rate of turbulent kinetic energy

- \(\beta \) :

-

Thermal expansion coefficient (1/K)

- \({\delta }_{\text{s}}\) :

-

Slag skin thickness (m)

- \({\delta }_{\text{m}}\) :

-

Copper mold thickness (m)

- \(\varepsilon \) :

-

Dissipation rate of turbulent kinetic energy (m2/s3)

- \(\eta \) :

-

Magnetic diffusion coefficient

- θ :

-

Tangential coordinate

- \(\mu \) :

-

Viscosity (Pa·s)

- \({\mu }_{0}\) :

-

Vacuum magnetic permittivity (F/m)

- \({\mu }_{\text{eff}}\) :

-

Effective viscosity (Pa·s)

- \({\mu }_{\text{t}}\) :

-

Turbulent viscosity (Pa·s)

- \(\rho \) :

-

Density (kg/m3)

- \(\sigma \) :

-

Electrical conductivity of mixture phase (S/m)

- \(\omega \) :

-

Angular frequency (Hz)

- \(\phi \) :

-

Physical property of mixture phase

- \({\phi }_{\text{m}}\) :

-

Physical property of metal

- \({\phi }_{\text{s}}\) :

-

Physical property of slag

References

B. Hernandez-Morales and A. Mitchell: Ironmak. Steelmak., 2013, vol. 26, pp. 423–38.

A. Kharicha, E. Karimi-Sibaki, M. Wu, A. Ludwig, and J. Bohacek: Steel Res. Int., 2018, vol. 89, p. 1700100.

J.W. Zhang, Z.B. Li, and X.Q. Che: J. Iron. Steel. Res. Int., 1997, vol. 9, pp. 7–12.

A. Mitchell: Mater. Sci. Eng. A, 2005, vol. 413–414, pp. 10–18.

K. Fezi, J. Yanke, and M.J.M. Krane: Metall. Mater. Trans. B, 2014, vol. 46B, pp. 766–79.

L.Z. Chang, X.F. Shi, H.S. Yang, and Z.B. Li: J. Iron Steel Res. Int., 2009, vol. 16, pp. 7–11.

H. Cao, Z. Jiang, Y. Dong, F. Liu, Y. Cao, Z. Hou, K. Yao, and M. Xu: Steel Res. Int., 2018, vol. 90, p. 1800337.

X. Huang, Z. Liu, Y. Duan, C. Liu, and B. Li: J Mater. Res. Technol., 2022, vol. 20, pp. 3843–59.

F. Wang, Q. Wang, and B. Li: ISIJ Int., 2017, vol. 57, pp. 91–99.

X. Huang, Y. Duan, Z. Liu, B. Li, and F. Wang: Metals, 2021, vol. 11, p. 1675.

Q. Wang and B. Li: ISIJ Int., 2016, vol. 56, pp. 282–87.

A. Mitchell and B. Hernandez-Morales: Metall. Mater. Trans. B, 1990, vol. 21B, pp. 723–31.

Q. Wang, H. Yan, F. Wang, and B. Li: JOM, 2015, vol. 67, pp. 1821–29.

Y.B. Zhong, Q. Li, Y.P. Fang, H. Wang, M.H. Peng, L.C. Dong, T.X. Zheng, Z.S. Lei, W.L. Ren, and Z.M. Ren: Mater. Sci. Eng. A, 2016, vol. 660, pp. 118–26.

Y. Guo, W. Qi, Z. Xia, W. Lin, C. Liu, P. Shi, Q. Li, Z. Shen, B. Ding, T. Zheng, and Y. Zhong: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 3384–95.

H. Wang, Y. Zhong, Q. Li, Y. Fang, W. Ren, Z. Lei, and Z. Ren: ISIJ Int., 2016, vol. 56, pp. 255–63.

X. Zhao, Z. Sun, Z. Xia, C. Liu, Z. She, B. Ding, T. Zheng, Y. Guo, Q. Li, and Y. Zhong: Metals, 2023, vol. 13, p. 912.

Q. Li, Z. Xia, Y. Guo, Z. Shen, T. Zheng, B. Ding, and Y. Zhong: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1495–1507.

Z.B. Li: Principle and Practice of Electroslag Metallurgy, Metallurgical Industry Press, Beijing, 2010, pp. 21–25.

J. Yu, F. Liu, Z. Jiang, C. Kang, K. Chen, H. Li, and X. Geng: Steel Res. Int., 2018, vol. 89, p. 1700481.

V. Weber, A. Jardy, B. Dussoubs, D. Ablitzer, S. Rybéron, V. Schmitt, S. Hans, and H. Poisson: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 271–80.

A.H. Dilawari and J. Szekely: Metall. Mater. Trans. B, 1977, vol. 8B, pp. 418–21.

M. Hugo, B. Dussoubs, A. Jardy, J. Escaffre, and H. Poisson: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 2607–22.

Y.M. Ferng, C.C. Chieng, and C. Pan: Numer. Heat Transf. A, 1989, vol. 16, pp. 429–49.

A. Rückert and H. Pfeifer: Metals, 2007, vol. 24, pp. 2–8.

E. Karimi-Sibaki, A. Kharicha, J. Bohacek, M. Wu, and A. Ludwig: Adv. Eng. Mater., 2016, vol. 18, pp. 224–30.

Q. Wang, R. Zhao, M. Fafard, and B. Li: Appl. Therm. Eng., 2015, vol. 80, pp. 178–86.

Q. Wang, Z. He, B. Li, and F. Tsukihashi: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 2425–41.

Q. Wang, L. Gosselin, and B. Li: ISIJ Int., 2014, vol. 54, pp. 2821–30.

A. Mitchell: Mater. Sci. Technol., 2013, vol. 25, pp. 186–90.

A. Kharicha, W. Schützenhöfer, A. Luding, R. Tanzer, and M. Wu: Steel Res. Int., 2008, vol. 79, pp. 632–36.

X. Huang, B. Li, Z. Liu, X. Yang, and F. Tsukihashi: Int. J. Heat Mass Transf., 2019, vol. 135, pp. 1300–11.

Y. Dong, Z. Jiang, H. Cao, X. Wang, Y. Cao, and D. Hou: ISIJ Int., 2016, vol. 56, pp. 1386–93.

S. Spitans, H. Franz, H. Scholz, G. Reiter, and E. Baake: Magnetohydrodynamics, 2017, vol. 53, pp. 557–69.

J. Yu, Z. Jiang, F. Liu, K. Chen, H. Li, and X. Geng: ISIJ Int., 2017, vol. 57, pp. 1205–12.

Z.H. Jiang: Electroslag Metallurgy, Science Press, Beijing, 2015, pp. 243–44.

Acknowledgments

The authors gratefully acknowledged the financial support of the National Key Research and Development Program of China (2022YFC2904900), Young Elite Scientists Sponsorship Program by CAST (2022QNRC001), Shi Changxu Innovation Center for Advanced Materials (SCXKFJJ202204), Science and Technology Commission of Shanghai Municipality (21SQBS00700), and the National Natural Science Foundation of China (52004156, 52274385, 52204392, 52204347).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xia, Z., Sun, Z., Zhang, M. et al. Numerical Investigation About the Effect of Axial Static Magnetic Field on Improvement of Metal Pool Profile During Electroslag Remelting Process. Metall Mater Trans B 54, 3101–3114 (2023). https://doi.org/10.1007/s11663-023-02893-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02893-3