Abstract

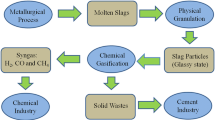

Silicon slag (SS) and Ti-bearing blast furnace slag (TBFS) are large-scale waste slags produced in the metallurgical industry that contain rich Si and Ti resources. In this paper, an innovative process is proposed to produce Si–Ti alloy by the co-reduction of SS and TBFS to achieve simultaneous treatment of both waste slags. Si in SS was used as reducing agent to reduce TiO2 in TBFS to produce Si–Ti alloy. The possibility of Si reduction of TiO2 was determined by thermodynamic calculation, and the experimental results indicated that the key to the reaction process lies in the decrease in activity of SiO2 in slag. The slag viscosity can be reduced by adding CaO, which can enhance the enrichment effect of the alloy. The Si–Ti alloy was successfully prepared by the co-reduction experiment of these two waste slags. Additionally, an investigation of the mechanism of SS and TBFS co-reduction was conducted. The proposed process is simple, environmentally friendly, and provides a novel and clean way for the effective utilization of SS and TBFS.

Similar content being viewed by others

References

S.C. Shit and P. Shah: Natl. Acad. Sci. Lett., 2013, vol. 36, pp. 355–65.

T.R. Gilmanshina, A.I. Anikin, A.A. Kovaleva, S.I. Lytkina, S.A. Khudonogov, D.S. Voroshilov, M.V. Voroshilova, O.A. Masanskiy, and I.A. Kaposhko: Int. J. Adv. Manuf. Technol., 2021, vol. 112, pp. 2313–25.

T. Ando and X.A. Fu: Sens. Actuators A, 2019, vol. 296, pp. 340–51.

G. Li, Y. Lu, Q. Xuan, Y.G. Akhlaghi, G. Pei, J. Ji, and X. Zhao: Sol. Energy, 2020, vol. 202, pp. 316–25.

F. Chigondo: Silicon, 2018, vol. 10, pp. 789–98.

M. Moen, T. Halvorsen, K. Mørk, and S. Velken: Met. Powder Rep., 2017, vol. 72, pp. 182–87.

I. Kero, M.K. Næss, V. Andersen, and G.M. Tranell: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1186–94.

N. Tan, H. Li, Z. Ding, K. Wei, W. Ma, D. Wu, and S. Han: Int. J. Hydrogen Energy, 2021, vol. 46, pp. 23406–16.

D. Qiao, S. Liang, J.G. Zhao, X.J. Peng, Y. Nie, Y.X. Li, Y. Cui, and G. Sun: Silicon, 2022, vol. 14, pp. 5029–34. https://doi.org/10.1007/s12633-021-01253-7.

Q. He, H. Zhao, S. Qian, Q. Zhou, J. Wu, and W. Ma: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 442–53.

Q. Zhou, J. Wen, J. Wu, W. Ma, M. Xu, K. Wei, Z. Zhang, L. Zhang, and J. Xu: J. Clean. Prod., 2019, vol. 229, pp. 1335–41.

R.K. Chinnam, A.A. Francis, J. Will, E. Bernardo, and A.R. Boccaccini: J. Non-Cryst. Solids, 2013, vol. 365, pp. 63–74.

A. Rincón, M. Marangoni, S. Cetin, and E. Bernardo: J. Chem. Technol. Biotechnol., 2016, vol. 91, pp. 1946–61.

J. Cao, J. Lu, L. Jiang, and Z. Wang: Ceram. Int., 2016, vol. 42, pp. 10079–84.

F. Zheng, Y. Guo, G. Qiu, F. Chen, S. Wang, Y. Sui, T. Jiang, and L. Yang: J. Hazard. Mater., 2018, vol. 344, pp. 490–98.

Y. Cai, N. Song, Y. Yang, L. Sun, P. Hu, and J. Wang: Int. J. Miner. Metall. Mater., 2022, vol. 29, pp. 22–31.

Q.Y. Huang, X.W. Lv, R. Huang, and J.J. Song: Can. Metall. Q., 2013, vol. 52, pp. 413–21.

S. He, H. Sun, D.G. Tan, and T. Peng: Procedia Environ. Sci., 2016, vol. 31, pp. 977–84.

Z. Chen, Y. Li, Y. Tan, and K. Morita: Mater. Trans., 2015, vol. 56, pp. 1919–22.

Z. Chen, Y. You, and K. Morita: ACS Sustain. Chem. Eng., 2018, vol. 6, pp. 7078–85.

G.X. Qiu, D.J. Miao, X.L. Wei, C. Bai, and X.M. Li: J. Non-Cryst. Solids, 2022, vol. 585, p. 121545. https://doi.org/10.1016/j.jnoncrysol.2022.121545.

J. Shi, L. Sun, J. Qiu, B. Zhang, and M. Jiang: J. Alloys Compd., 2017, vol. 699, pp. 193–99.

A. Shankar, M. Görnerup, A.K. Lahiri, and S. Seetharaman: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 911–15.

S. Han, N. Tan, K. Wei, and W. Ma: Sep. Purif. Technol., 2022, vol. 280, p. 119815.

X. Wang, Z. Wen, Y. Liu, L. Huang, and M. Wu: J. Alloys Compd., 2010, vol. 506, pp. 317–22.

G.A. Khater: Ceram. Int., 2011, vol. 37, pp. 2193–99.

S. Blotevogel, L. Steger, D. Hart, L. Doussang, J. Kaknics, M. Poirier, H. Bornhöft, J. Deubener, C. Patapy, and M. Cyr: J. Am. Ceram. Soc., 2021, vol. 104, pp. 128–39.

H. Sakiani, S.H. Tabaian, J. Chen, J. Li, and B. Ban: Sep. Purif. Technol., 2020, vol. 250, p. 117227.

S.-L. Zhang and U. Smith: J. Vac. Sci. Technol. A, 2004, vol. 22, pp. 1361–70.

Acknowledgments

The authors wish to acknowledge the financial support on this research from the National Natural Science Foundation of China (22078140), the Talent Training Program of Yunnan of China (202005AC160041) and the major R&D project of Yunnan of China (202002AB0800020102).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gu, H., Cao, J., Wu, J. et al. A Novel Method for Preparing Si–Ti Alloy by Co-Reduction of Silicon Slag and Ti-Bearing Blast Furnace Slag. Metall Mater Trans B 54, 2815–2823 (2023). https://doi.org/10.1007/s11663-023-02876-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02876-4