Abstract

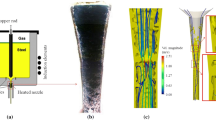

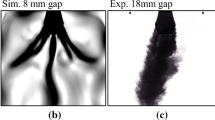

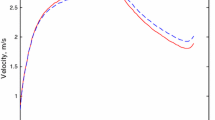

In this paper, the user-defined function (UDF) is firstly used to couple the porous medium model and the Euler–Euler two-fluid model, and the integrated SEN clogging model including the SEN clogging formation and growth, and liquid steel fluid flow dominated by the deposition of non-metallic inclusion particles is established. The simulation results of the SEN clogging under the Euler–Euler and Euler–Lagrange frameworks are both in good agreement with the measured results. With the increase of the distance from the nozzle inlet, the clogging thickness first increases, then remains stable, and slightly decreases. The clogging at the bottom of the nozzle is most serious and presents a conical shape. The polyhedral mesh is better than that of the hexahedral structure mesh for SEN clogging simulation. With the flow space of molten steel extruded and clogged, the molten steel jet is concentrated and strengthened under the constant steel throughput. The average inclination angle of molten steel jet from the nozzle side port first increases and then decreases slightly with time. The volume fraction of the clogging increases rapidly at first, and then the growth rate of the clogging decreases.

Adapted from Ref. [51] with permission of Elsevier

Similar content being viewed by others

Abbreviations

- \(K = {\text{L}},{\text{S}}\) :

-

Liquid phase and solid phase, respectively, (–)

- \(\alpha_{K}\) :

-

Volume fraction, (–)

- \(\rho\) :

-

Density, (kg/m3)

- \(\overrightarrow {u}_{K}\) :

-

Velocity vector, (m/s)

- \(t\) :

-

Time, (s)

- \(\tau_{K}\) :

-

Shear pressure, (Pa)

- \(p\) :

-

Pressure, (Pa)

- \(\overrightarrow {g}\) :

-

Acceleration of gravity, (m/s2)

- \(F_{K}\) :

-

Interface force between two phases, (N)

- \(\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}}{{S_{u} }}\) :

-

Darcy source terms of continuous phase velocity, (–)

- \(F_{{{\text{L}},K}}\) :

-

Lift force, (N)

- \(F_{{{\text{D}},K}}\) :

-

Drag force, (N)

- \(F_{{{\text{V}},K}}\) :

-

Virtual mass force, (N)

- \(F_{{{\text{td}},K}}\) :

-

Turbulent dispersion force, (N)

- \({\text{I}}\) :

-

Unit tensor, (–)

- \(\mu_{{{\text{eff}},K}}\) :

-

Effective viscosity, (Pa s)

- \(\mu_{{\text{L}}}\) :

-

Molecular viscosity, (Pa s)

- \(\mu_{{\text{T}}}\) :

-

Turbulent viscosity, (Pa s)

- \(\mu_{{{\text{BI}}}}\) :

-

Equivalent viscosity, (Pa s)

- \(G_{k}\) :

-

Production terms of \(k\), (–)

- \(G_{\omega }\) :

-

Production terms of \(\omega\), (–)

- \(\Gamma_{k}\) :

-

Equivalent diffusivity of \(k\), (–)

- \(\Gamma_{\omega }\) :

-

Equivalent diffusivity of \(\omega\), (–)

- \(k\) :

-

Turbulent kinetic energy, (–)

- \(\omega\) :

-

Specific dissipation rate, (–)

- \(Y_{k}\) :

-

Turbulent dissipation term of \(k\), (–)

- \(Y_{\omega }\) :

-

Turbulent dissipation term of \(\omega\), (–)

- \(S_{k}\) :

-

Source terms of \(k\), (–)

- \(S_{\omega }\) :

-

Source terms of \(k\), (–)

- \(G_{b}\) :

-

Buoyancy terms of \(k\), (–)

- \(G_{\omega b}\) :

-

Buoyancy terms of \(\omega\), (–)

- \(F_{{\text{A}}}\) :

-

Adhesion force, (N)

- \(F_{{\text{B}}}\) :

-

Buoyancy force, (N)

- \(\kappa_{{\text{S}}}\) :

-

Friction coefficient, (–)

- \(r_{1}\) :

-

Particle radius, (m)

- \(a\) :

-

Contact radius, (m)

- \(R_{{\text{N}}}\) :

-

Normal ratio, (–)

- \(R_{{\text{P}}}\) :

-

Parallel ratio, (–)

- \(R_{{\text{T}}}\) :

-

Torque ratio, (–)

- \(K_{{{\text{per}}}}\) :

-

Permeability, (–)

- \(\overline{{f_{{\text{p}}} }}\) :

-

Average solid volume fraction of the clog, (–)

- \(D_{{{\text{pore}}}}\) :

-

Diameter of the large hole in the clog, (m)

- \(f_{{{\text{clog}}}}\) :

-

Volume fraction of clog in the cell, (–)

- \(f_{{\text{p}}}\) :

-

The volume fractions of solid phase, (–)

- \(S_{k}\) :

-

Darcy source terms of turbulent kinetic energy, (–)

- \(S_{\omega }\) :

-

Darcy source terms of specific dissipation rate, (–)

- \(F_{{\text{P}}}\) :

-

Pressure gradient force, (N)

- \(F_{{\text{g}}}\) :

-

Gravity, (N)

- \(m_{{\text{b}}}\) :

-

Mass of discrete particles, (kg)

- \(\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}}{{u_{{\text{b}}} }}\) :

-

Velocity of discrete particles, (m/s)

- \(C_{{\text{D}}}\) :

-

Drag force coefficients, (–)

- \(C_{{\text{L}}}\) :

-

Lift force coefficients, (–)

- \(C_{{\text{V}}}\) :

-

Virtual mass force coefficients, (–)

- \(d_{{\text{b}}}\) :

-

Diameter of discrete particles, (m)

- \(\rho_{{\text{b}}}\) :

-

Density of discrete particles, (kg/m3)

- \(\overrightarrow {{u^{\prime}}}\) :

-

Time averaged velocity, (m/s)

- \(\xi\) :

-

Gaussian distributed random number, (m/s)

- \(\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}}{{u_{{{\text{in}}}} }}\) :

-

Average velocity of the inclusion at this point and time, (m/s)

- \(u_{{{\text{nor}}}}\) :

-

Velocity projection of \(\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}}{{u_{{{\text{in}}}} }}\) in the normal direction of the plane, (m/s)

- Φ(·):

-

Cumulative distribution function of the standard normal distribution, (–)

- Ψ(·):

-

Density function of the standard normal distribution, (–)

- \(\Delta f_{{\text{p}}}\) :

-

Cumulative distribution function of the standard normal distribution, (–)

- S :

-

Area of the mesh surface, (m2)

- \(c_{inclusion}\) :

-

Inclusion concentration, (–)

- \(\Delta t\) :

-

Time step, (s)

- \(V_{{{\text{cell}}}}\) :

-

The mesh volume, (m3)

References

M.J. Long, X.G. Zuo, L.F. Zhang, and D.F. Chen: ISIJ Int., 2010, vol. 50(5), pp. 712–20.

Y. Vermeulen, B. Coletti, B. Blanpain, P. Wollants, and J. Vleugels: ISIJ Int., 2002, vol. 42(11), pp. 1234–40.

C.J. Zhang, Y.L. Bi, H.J. Zhang, and J. Yang: Adv. Mater. Res., 2011, vol. 284, pp. 1306–10.

W.J. Lee, J.G. Kim, J.I. Jung, and K.Y. Huh: Steel Res. Int., 2021, vol. 92, p. 2000506.

X.F. Qin, C.G. Cheng, Y.L. Li, W.L. Wu, and Y. Jin: J. Iron. Steel Res. Int., 2021, vol. 29(4), pp. 588–600.

R. Sambasivam: Ironmak. Steelmak., 2006, vol. 33(6), pp. 439–53.

G.C. Duderstadt, R.K. Iyengar, and J.M. Matesa: JOM, 1968, vol. 20(4), pp. 89–94.

E. Roos, A. Karasev, and P.G. Jonsson: Steel Res. Int., 2015, vol. 86(11), pp. 1279–88.

J. Szekely and S.T. DiNovo: Metall. Trans., 1974, vol. 5(3), pp. 747–54.

K. Sasai and Y. Mizukami: ISIJ Int., 1995, vol. 35(1), pp. 26–33.

V. Brabie: ISIJ Int., 1996, vol. 36, pp. 109–12.

R.B. Tuttle, J.D. Smith, and K.D. Peaslee: Metall. Mater. Trans. B., 2007, vol. 38B(1), pp. 101–08.

R.B. Tuttle, J.D. Smith, and K.D. Peaslee: Metall. Mater. Trans. B, 2005, vol. 36B(6), pp. 885–92.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B., 2001, vol. 32B(4), pp. 707–22.

M. Suzuki, Y. Yamaoka, N. Kubo, and M. Suzuki: ISIJ Int., 2002, vol. 42(3), pp. 248–56.

B.G. Thomas and H. Bai: Effects of Clogging, Argon Injection, and Continuous Casting Conditions on Flow and Air Aspiration in Submerged Entry Nozzles, vol. 18, Iron and Steel Society, Warrendale, 2001.

Z.Y. Deng, M.Y. Zhu, Y.L. Zhou, and S.C. Du: Metall. Mater. Trans. B., 2016, vol. 47B(3), pp. 2015–25.

M. Guingo and J.P. Minier: Phys. Fluids, 2008, vol. 20(5), p. 053303.

L.F. Zhang and B.G. Thomas: Metall. Mater. Trans. B., 2006, vol. 37B(5), pp. 733–61.

N. Kojola, S. Ekerot, M. Andersson, and P.G. Jönsson: Ironmak. Steelmak., 2011, vol. 38(1), pp. 1–11.

N. Kojola, S. Ekerot, and P. Jönsson: Ironmak. Steelmak., 2011, vol. 38(2), pp. 81–89.

M. Mohammadi-Ghaleni, M.A. Zaeem, J.D. Smith, and R. O’Malley: Metall. Mater. Trans. B, 2016, vol. 47B(6), pp. 3384–93.

E. Gutierrez, S. Garcia-Hernandez, and J.D. Barreto: ISIJ Int., 2016, vol. 56(8), pp. 1394–1403.

P.Y. Ni, L.T.I. Jonsson, M. Ersson, and P.G. Jönsson: ISIJ Int., 2013, vol. 53(5), pp. 792–801.

D. Eskin, J. Ratulowski, and K. Akbarzadeh: Chem. Eng. Sci., 2011, vol. 66(20), pp. 4561–72.

C. Henry and J.P. Minier: Prog. Energy Combust. Sci., 2014, vol. 45, pp. 1–53.

P.Y. Ni, L.T. Jonsson, M. Ersson, and P.G. Jönsson: Steel Res. Int., 2017, vol. 88, p. 1800494.

C. Henry, J.P. Minier, and G. Lefèvre: Adv. Colloids Interfaces Sci., 2012, vol. 185, pp. 34–76.

A. Soldati and C. Marchioli: Int. J. Multiph. Flow, 2009, vol. 35(9), pp. 827–39.

H. Barati, M. Wu, A. Kharicha, and A. Ludwig: Powder Technol., 2018, vol. 329, pp. 181–98.

C. Caruyer, J.P. Minier, M. Guingo, and C. Henry: Advances in Hydroinformatics, Springer, Singapore, 2014, pp. 597–612.

K. Sasai and Y. Mizukami: ISIJ Int., 2001, vol. 41(11), pp. 1331–39.

F. Heuzeroth, J. Fritzsche, E. Werzner, M.A.A. Mendes, S. Ray, D. Trimis, and U.A. Peuker: Powder Technol., 2015, vol. 283, pp. 190–98.

C. Henry, J.P. Minier, and G. Lefèvre: Langmuir, 2012, vol. 28(1), pp. 438–52.

G. Li, C.X. Lu, M.J. Gan, Q.Q. Wang, and S.P. He: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1436–45.

B. Li, H.B. Lu, Z. Shen, X.H. Sun, Y.B. Zhong, Z.M. Ren, and Z.S. Lei: ISIJ Int., 2019, vol. 59(12), pp. 2264–71.

H.C. Zhou, L.F. Zhang, Q.Y. Zhou, W. Chen, R.B. Jiang, K. Yin, and W. Yang: Steel Res. Int., 2020, vol. 92.

J.B. Li, T. Zhang, F.B. Gao, Y.K. Gong, and D. Zhou: Int. J. Chem. React. Eng., 2022, pp. 1027–33.

E. Gutierrez, S. Garcia-Hernandez, and J.D. Barreto: Steel Res. Int., 2016, vol. 87(11), pp. 1406–16.

Y.D. Wu, Z.Q. Liu, B.K. Li, L.J. Xiao, and Y. Gan: Powder Technol., 2022, vol. 402.

S.S. Long, X.G. Yang, J. Yang, and M. Sommerfeld: Chem. Eng. J., 2022, vol. 445.

M. Pourtousi, P. Ganesan, and J.N. Sahu: Measurement, 2015, vol. 76, pp. 255–70.

R.J.G. Lopes and R.M. Quinta-Ferreira: Chem. Eng. J., 2010, vol. 160(1), pp. 293–301.

W.D. Yang, Z.G. Luo, Y.G. Gu, Z.Y. Liu, and Z.S. Zou: ISIJ Int., 2020, vol. 60(10), pp. 2234–45.

W.D. Yang, Z.G. Luo, Y.G. Gu, Z.Y. Liu, and Z.S. Zou: Powder Technol., 2019, vol. 361, pp. 769–81.

W.D. Yang, Z.G. Luo, Z.S. Zou, C.X. Zhao, and Y. You: Powder Technol., 2021, vol. 390, pp. 387–400.

P.Y. Ni, L.T.I. Jonsson, M. Ersson, and P.G. Jönsson: Int. J. Multiph. Flow, 2014, vol. 62, pp. 152–60.

P.Y. Ni, L.T.I. Jonsson, M. Ersson, and P.G. Jönsson: Int. J. Heat Fluid Flow, 2016, vol. 62, pp. 166–73.

P.Y. Ni, L.T.I. Jonsson, M. Ersson, and P.G. Jönsson: Metall. Mater. Trans. B., 2014, vol. 45B(6), pp. 2414–24.

H. Barati, M.H. Wu, T. Holzmann, A. Kharicha, and A. Ludwig: CFD Modeling and Simulation in Materials Processing, 2018, pp. 149–58.

C. Hua, Y. Bao, and M. Wang: Powder Technol., 2021, vol. 393, pp. 405–20.

H.A. Jakobsen, S. Grevskott, and H.F. Svendsen: Ind. Eng. Chem. Res., 1997, vol. 36(10), pp. 4052–74.

F.R. Menter: AIAA J., 1994, vol. 32(8), pp. 1598–1605.

U. Dieguez Salgado, C. Weiß, S.K. Michelic, and C. Bernhard: Metall. Mater. Trans. B, 2018, vol. 49B(4), pp. 1632–43.

X.H. Yang, T.J. Lu, and T.B. Kim: Phys. Lett. A, 2014, vol. 378(30–31), pp. 2308–11.

D.W. Tang and Z.Z. Cai: Adv. Appl. Math., 2019, vol. 8(4), pp. 12–23.

D. Gidaspow and D.J. Bezburuahr: Department of Chemical Engineering, 1991.

A.D. Burns, T. Frank, and I. Hamill: 5th International Conference on Multiphase Flow, Yokohama, 2004, vol. 4, pp. 1–17.

M. Sosnowski, J. Krzywanski, K. Grabowska, R. Gnatowska, and P. Dančová: The European Physical Journal Conferences, 2018, vol. 180, p. 02096.

W. Wang, Y. Cao, and T. Okaze: Build. Environ., 2021, vol. 195.

A.L. Kulkarni and A.W. Patwardhan: Chem. Eng. Res. Des., 2014, vol. 92(7), pp. 1227–48.

H. Barati, M. Wu, A. Kharicha, and A. Ludwig: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 1428–43.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (U1960202).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, JQ., Liu, YB., Sun, Q. et al. Numerical Simulation of Transient Submerged Entry Nozzle Clogging With Euler–Euler and Euler–Lagrange Frameworks. Metall Mater Trans B 54, 2629–2650 (2023). https://doi.org/10.1007/s11663-023-02863-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02863-9