Abstract

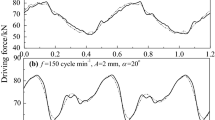

During the continuous casting process, the instantaneous abnormal mold level fluctuation has great detrimental effects on slab quality, thus the mold level fluctuation is a key parameter for continuous casting process of high-quality steel. In the present study, the slab continuous casting process data for low carbon steel, medium carbon steel, hypo-peritectic steel and peritectic steel are collected to investigate the effect of process parameter on the instantaneous abnormal mold level fluctuation. The frequency domain coherence results illustrate that the stopper-rod position is the key influence factor on the instantaneous abnormal mold level fluctuation during the continuous casting process of different steel grades. The time–frequency characteristics of instantaneous abnormal mold level fluctuation and stopper-rod position were analyzed by continuous wavelet transform (CWT), and the results show that before the instantaneous abnormal mold level fluctuation occurrence, the high-frequency region amplitude of stopper-rod position shows a linear increase trend. For the continuous casting process with constant casting speed, the increase rate is within the range of 0.1/s to 0.2/s. For the instantaneous abnormal mold level fluctuation induced by steep casting speed change, the increase rate can reach 0.67/s. For the instantaneous abnormal mold level fluctuation induced by ladle change, the increase rate can reach 0.85/s. Therefore, the instantaneous abnormal mold level fluctuation can be predicted by CWT analysis for the high-frequency region amplitude of stopper-rod position.

Similar content being viewed by others

References

The World Steel Association (worldsteel): World Steel in Figures 2022, https://worldsteel.org/steel-topics/statistics/world-steel-in-figures-2022/, accessed 6 June 2022.

G.A. Panaras, A. Theodorakakos, and G. Bergeles: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 1117–26.

M. Iguchi, J. Yoshida, T. Shimizu, and Y. Mizuno: ISIJ Int., 2000, vol. 40, pp. 685–91.

H. Lei, H.H. Xu, M.Y. Zhu, Y. Gan, X. Liu, M.S. Ni, and L.J. Qi: Steel. Iron., 1999, vol. 34, pp. 171–75.

Y. Li, X.H. Zhang, P. Lan, and J.Q. Zhang: Int. J. Miner. Metall. Mater., 2013, vol. 20, pp. 138–45.

M. Dussud, F. Montegu, and G. Kim: Proceedings of AISTech Conference, Cleveland American, Cleveland, 2006, pp. 995–1003.

X. Huang and B.G. Thomas: Can. Metall. Q., 1998, vol. 37, pp. 197–212.

Y.J. Jeon, H.J. Sung, and S. Lee: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 121–30.

T. Teshima, J. Kubota, M. Suzuki, K. Ozawa, T. Masaoka, and S. Miyahara: Tetsu-to-Hagané, 1993, vol. 79, pp. 576–82.

Z.K. Jiang, Z.J. Su, C.Q. Xu, J. Chen, and J.C. He: J. Iron Steel Res. Int., 2020, vol. 27, pp. 160–68.

K.T. Zhang, J.H. Liu, H. Liu, and C. Xiao: Metal. Material. Trans. B, 2018, vol. 49, pp. 1174–84.

Y. Ma, C. Peng, W. Gui, and F.Y. Wang: J. Iron Steel Res. Int., 2015, vol. 22, pp. 785–94.

Y. Ma, B.H. Fang, Q.Q. Ding, and F.Y. Wang: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 558–68.

Q.W. Wang: Master’s Thesis, Zhejiang University, 2002.

F. Al-Badour, M. Sunar, and L. Cheded: Mech. Syst. Signal Process., 2011, vol. 25, pp. 2083–2101.

H. Lei, J.J. Liu, G.F. Tang, H.W. Zhang, Z.K. Jiang, and P. Lv: JOM J. Miner. Met. Mater. Soc., 2023, vol. 75, pp. 914–19.

Acknowledgments

The authors gratefully acknowledge the financial support of National Key Research and Development Plan (No. 2021YFB3702000) and National Natural Science of China (Nos. 52074076, 52174306 and U20A20272) and Fundamental Research Funds for the Central Universities No. N2225023.

Competing interests

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meng, X., Luo, S., Zhou, Y. et al. Time–Frequency Characteristics and Predictions of Instantaneous Abnormal Level Fluctuation in Slab Continuous Casting Mold. Metall Mater Trans B 54, 2426–2438 (2023). https://doi.org/10.1007/s11663-023-02844-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02844-y