Abstract

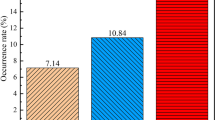

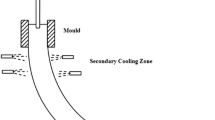

During the continuous casting, the mold level fluctuation (MLF) is one of the key parameters to limit the casting speed and the slab quality. Industrial practices show that the steel grades with different carbons have different MLFs. The MLF is up to 10 mm for hypo-peritectic steel (the carbon content is close to the maximum saturated solubility of carbon in δ ferrite), 3 mm for peritectic steel (carbon content is close to the peritectic point), and < 2 mm for ultra-low carbon steel and low carbon steel. Power spectral density is an effective method to determine the characteristic frequency of abnormal MLF and the resonance phenomenon, and the frequency domain data with zero amplitude of harmonic wave at a specified frequency are an effective method to determine the main frequency of abnormal MLF. For hypo-peritectic steel (w[C] = 0.13), the abnormal MLF comes from the harmonic wave of 0.32 Hz, and the MLF resonance occurs because the main frequency of the MLF is close to the withdraw force. Volume contraction and the uneven thickness of the solidified shell are two key factors that affect the MLF.

Similar content being viewed by others

References

A. Matsushita, K. Isogami, M. Temma, and T. Ninomiya, Trans. ISIJ 7, 531 (1988).

H. Lei, H. Xu, M. Zhu, and Y. Gan, Steel. Iron. 8, 20 (1999).

R. Miranda, M.A. Barron, J. Barreto, L. Hoyos, and J. Gonzalez, ISIJ Int. 11, 1626 (2005).

B. Shen, H. Shen, and B.C. Liu, ISIJ Int. 3, 427 (2007).

B.Z. Shen, H.F. Shen, and B.C. Liu, Ironmak Steelmak. 1, 33 (2009).

H. Zhang and W. Wang, Metall. Mater. Trans. B 2, 920 (2016).

H. Ohno, Y. Miki, and Y. Nishizawa, ISIJ Int. 10, 1758 (2016).

Y. Yin, J. Zhang, B. Wang, and Q. Dong, Ironmak Steelmak. 7, 682 (2019).

H. Duan, X. Wang, M. Yao, Y. Liu, and YYu. Mater, Trans. B 4, 1656 (2020).

K. Zhang, J. Liu, H. Cui, and C. Xiao, Metall. Mater. Trans. B 3, 1174 (2018).

Z.K. Jiang, Z.J. Su, C.Q. Xu, J. Chen, and J.C. He, J. Iron Steel Res. Int. 2, 160 (2020).

J. Yang, D. Chen, M. Long, and H. Duan, J. Mater. Res. Technol. 3, 3984 (2020).

C.L.M. Alves, J. Rezende, D. Senk, and J. Kundin, J. Mater. Res. Technol. 1, 233 (2019).

J.D. Lee and C.H. Yim, ISIJ Int. 8, 765 (2000).

H. Bayani, S.M.H. Mirbagheri, and M. Barzegari, J. Mater. Res. Technol. 1, 55 (2014).

P. Presoly, R. Pierer, and C. Bernhard, Metall. Mater. Trans. A. 6, 5377 (2013).

G. Azizi, B.G. Thomas, and M.A. Zaeem, Metall. Mater. Trans. B 5, 2020 (1875).

Q.Q. Ren, T. Liu, S. Balk, Z.G. Mao, and B.W. Krakauer, J. Mater. Sci. 10, 6448 (2021).

M. Suzuki and Y. Yamaoka, Mater. Trans. 3, 836 (2003).

H. Mizukami and A. Yamanaka, ISIJ Int. 3, 435 (2010).

Y. Sugitani and M. Nakamura, Tetsu-to-Hagane 12, 1702 (1979).

T. Kajitani, H. Esaka, M. Wakoh, H. Misumi, and S. Ogibayashi, Tetsu-to-Hagane 11, 1055 (1995).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Density change and volume change

Appendix: Density change and volume change

Or the steel with mass m, the density and the volume are \(\rho_{1}\) and \(V_{1}\) at the temperature \(T_{1}\), and the density and volume are \(\rho_{2}\) and \(V_{2}\) at the temperature \(T_{2}\). Then, the related volume change from the temperature \(T_{1}\) to the temperature \(T_{2}\) can be expressed as follows.

Thus, the volume variation with the temperature can be expressed by the density variation with the temperature.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lei, H., Liu, J., Tang, G. et al. Deep Insight into Mold Level Fluctuation During Casting Different Steel Grades. JOM 75, 914–919 (2023). https://doi.org/10.1007/s11837-022-05668-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05668-4