Abstract

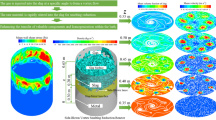

The smelting reduction of vanadium–titanium magnetite (VTM) with oxygen-rich side-blown bath smelting furnace (OSBF) is a promising process. However, the study on the behavior of gas–liquid multiphase flow in the OSBF in ironmaking process is deficient. In present work, a 3D simulation model of the OSBF is established to investigate the multiphase flow of gas–slag–metal in the furnace during the VTM smelting process. The bubbles motion, slag phase distribution, flow field distribution, and the flow status in the bath during the smelting process are obtained by combining the Coupled Level Set Volume of Fluid (CLSVOF) method and the Realizable k-ε model. The analysis of the characteristics of gas–slag–metal multiphase flow in the horizontal and vertical directions in the bath indicates that the gas and slag in the bath are evenly mixed, the fluctuation of the slag iron interface is subtle, and the turbulence of the molten iron layer is weak, which is conductive to the smelting process. In addition, the effects of primary air flow, slag layer thickness, and slag viscosity on the smelting process are also studied, and the appropriate operation conditions were recommended. This provides a theoretical basis for the operation and optimization design of the OSBF.

Similar content being viewed by others

Abbreviations

- A 0 :

-

Model constant, A0 = 4.04

- A S :

-

Model constant

- C 1ε :

-

Model constant, C1ε = 1.44

- C 2 :

-

Model constant, C2 = 1.9

- C 2ε :

-

Model constant, C2ε = 1.92

- C 3ε :

-

Model constant

- C μ :

-

Model parameter

- \(\overrightarrow {F}\) :

-

Source term force, N

- \(\overrightarrow {F}_{\text{sf}}\) :

-

Surface tension, N

- H φ :

-

Heaviside function

- \(\overrightarrow {g}\) :

-

Gravitational acceleration, m s−2

- G b :

-

Turbulence generation due to buoyancy, kg (m−1 s−3)

- G k :

-

Turbulence generation due to the mean velocity gradient, kg (m−1 s−3)

- k:

-

Turbulent kinetic energy, m2 s−2

- \(\overrightarrow {n}\) :

-

Normal vector of the interface

- \(p\) :

-

Pressure, Pa

- S :

-

Modulus of the mean rate-of-strain tensor, 1 s−1

- \(\overrightarrow {u}\) :

-

Velocity vector, m s−1

- α :

-

Phase volume fraction

- δ :

-

Thickness of the interface, m

- ε :

-

Turbulent kinetic energy dissipation rate, m2 s−3

- κ :

-

Interface curvature, 1 m−1

- μ :

-

Dynamic viscosity, Pa s

- μ t :

-

Turbulent viscosity, Pa s

- ρ :

-

Density, kg m−3

- σ :

-

Surface tension coefficient, N m−1

- σ k :

-

Turbulent Prandtl numbers for k, σk = 1.0

- σ ε :

-

Turbulent Prandtl numbers for ε, σε = 1.2

- φ :

-

Level set function

- ω k :

-

Angular velocity, rad s−1

- Ω:

-

Mean rate-of-rotation tensor

- g :

-

Gas phase

- i, j :

-

Coordinate direction indices

- l :

-

Liquid phase

- q :

-

qth Phase fluid

References

J.H. Luo, K.H. Qiu, Y.C. Qiu, and P.C. Zhang: Adv. Mater. Res., 2013, vol. 813, pp. 292–97.

H.D. Yu, L.N. Wang, J.K. Qu, and T. Qi: J. Northeast Univ., 2020, vol. 41, pp. 275–81.

W.G. Fu, Y.C. Wen, and H.E. Xie: J. Iron Steel Res. Int., 2011, vol. 18, pp. 7–10, 18.

F. Safdar, Y. Zhang, S.L. Zheng, X. Chen, P. Sun, Y. Zhang, and P. Li: Hydrometallurgy, 2020, vol. 193, 105324.

L.H. Zhou, J. Wang, S.Y. Guo, L.Y. Chen, and Z.R. Li: Appl. Mech. Mater., 2012, vol. 185–185, pp. 949–53.

V.E. Roshchin, A.V. Asanov, and A.V. Roshchin: Russ. Metall., 2011, vol. 2011, pp. 499–508.

X.G. Zhang, L.J. Jia, B. Wang, and S.M. Meng: Shangdong Metall., 2019, vol. 41, pp. 39–42.

S. Wang, Y.F. Guo, T. Jiang, L. Yang, F. Chen, F.Q. Zheng, X.L. Xie, and M.J. Tang: JOM, 2017, vol. 69, pp. 1646–53.

M.Y. Wang, S.F. Zhou, X.W. Wang, B.F. Chen, H.X. Yang, S.K. Wang, and P.F. Luo: JOM, 2016, vol. 68, pp. 2698–703.

S. Nkosi, P. Dire, N. Nyambeni, and X.C. Goso: J. Sci. Afr. Inst. Miner. Metall., 2017, vol. 9–10, pp. 191–200.

X.H. Li, J. Kou, T.C. Sun, S.C. Wu, and Y.Q. Zhao: Int. J. Miner. Metall. Mater., 2020, vol. 27, pp. 301–09.

L.S. Zhao, L.N. Wang, T. Qi, D.S. Chen, H.X. Zhao, and Y.Y. Liu: Hydrometallurgy, 2014, vol. 149, pp. 106–09.

Y.M. Zhang, L.Y. Yi, L.N. Wang, D.S. Chen, W.J. Wang, Y.H. Liu, H.X. Zhao, and T. Qi: Int. J. Miner. Metall. Mater., 2017, vol. 24, pp. 504–11.

T. QI, D.S. Chen, L.Y. Yi, L.N. Wang, H.X. Zhao, Y.H. Liu, W.J. Wang, and H.D. Yu: China patent, 2015, No. 106854702A.

L.Y. Shi, Y.L. Zhen, D.S. Chen, L.N. Wang, and T. Qi: ISIJ int., 2018, vol. 58, pp. 627–32.

Y.M. Zhang, L.N. Wang, D.S. Chen, W.J. Wang, Y.H. Liu, H.X. Zhao, and T. Qi: Int. J. Miner. Metall. Mater., 2018, vol. 25, pp. 131–44.

L.M. Chen, Y.L. Zhen, G.H. Zhang, D.S. Chen, L.N. Wang, H.X. Zhao, F.C. Meng, and T. Qi: Int. J. Miner. Metall. Mater., 2022, vol. 29, pp. 239–47.

A.V. Balasanov, V.G. Verein, A.A. Tupikov, and A.B. Usachev: Metallurgist, 2010, vol. 54, pp. 205–09.

V.A. Romenets, V.S. Valavin, Y.V. Pokhvisnev, S.A. Makeev, and A.I. Gimmelfarb: Metallurgist, 2010, vol. 54, pp. 273–77.

T. Qi, L.Y. Yi, D.S. Chen, L.N. Wang, H.X. Zhao, Y.H. Liu, W.J. Wang, and H.D. Yu: Australia patent, 2020, No. 2017232157.

A.V. Grechko: Metallurgist, 2000, vol. 44, pp. 151–54.

T. Hirata, M. Ishikawa, and S. Anezak: ISIJ Int., 1992, vol. 32, pp. 182–89.

D. Obiso, S. Kriebitzsch, M. Reuter, and B. Meyer: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2403–20.

B. Wang, S.Y. Shen, Y.W. Ruan, S.Y. Cheng, W.J. Peng, and J.Y. Zhang: Acta. Metall. Sin., 2020, vol. 56, pp. 619–32.

L.M. Li, X.J. Li, Z.C. Zhu, and B.K. Li: Powder Technol., 2020, vol. 373, pp. 14–25.

H.L. Zhang, C.Q. Zhou, W.U. Bing, and Y.M. Chen: J. S. Afr. Inst. Miner. Metall., 2015, vol. 115, pp. 457–63.

Y.T. Liu, T.Z. Yang, Z. Cheng, Z.Y. Zhu, L. Zhang, and Q. Huang: Trans. Nonferrous Met. Soc. China, 2020, vol. 30, pp. 249–58.

Y.D. Xiao, T.T. Liu, Y.G. Zhou, Q.Q. Su, L.Z. Mu, T. Wei, H.H. Zhao, and F.Q. Liu: JOM, 2021, vol. 73, pp. 2724–32.

K. Zhao, Y.Z. Shen, Z. Kong, Q.R. Zhang, Y.Z. Zhang, Y. Shi, C.L. Zhen, X.F. Shi, and X.H. Zhang: J. Iron Steel Res. Int., 2021, vol. 28, pp. 965–77.

W.X. Dai, G.G. Cheng, S.J. Li, Y. Huang, G.L. Zhang, Y.L. Qiu, and W.F. Zhu: ISIJ Int., 2019, vol. 59, pp. 1214–23.

Q. Cao and L. Nastac: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1388–404.

B. Ashraf. Ali and S. Pushpavanam: Int. J. Multiphas. Flow, 2011, vol. 37, pp. 268–77.

G. Son and N. Hur: Numer. Heat Tr. B-Fund., 2002, vol. 42, pp. 523–42.

J.U. Brackbill, D.B. Kothe, and C. Zemach: J. Comput. Phys., 1992, vol. 100, pp. 335–54.

J.L. Lumley: Adv. Appl. Mech., 1979, vol. 18, pp. 123–76.

U. Schumann: Phys. Fluids, 1977, vol. 20, pp. 721–25.

T.H. Shih, J. Zhu, and J.L. Lumley: Comput. Methods Appl. Mech. Eng., 1995, vol. 125, pp. 287–302.

J.X. Chen: Data Manual for steelmaking, 2nd ed. Metallurgical Industry Press, Beijing, 2010, pp. 274–84.

K. Ito and R.J. Fruehan: Steel Res., 1989, vol. 60, pp. 151–56.

R. Jiang and R.J. Fruehan: Metall. Trans. B, 1991, vol. 28B, pp. 481–89.

Acknowledgments

This work is financially supported by National Key R&D Program of China (No. 2018YFC1900500, 2018YFC1900503), Strategic Priority Research Program of the Chinese Academy of Sciences (No. XDC04010100), National Natural Science Foundation of China (No. 21908231), Special Project for Transformation of Major Technological Achievements in Hebei Province (No. 19044012Z), President Fund of China Institute of Standardization (542022Y-9371), and Province Key R&D Program of Hebei (No. 20374105D).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bian, Z., Chen, D., Sun, L. et al. Numerical Simulation of Multiphase Flow in Ironmaking Process for Oxygen-Rich Side-Blown Bath Smelting Furnace. Metall Mater Trans B 54, 1352–1367 (2023). https://doi.org/10.1007/s11663-023-02766-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02766-9