Abstract

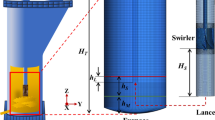

The change of bubbles and the position of the tuyere in an oxygen coal combustion melting and separating furnace affect the flow and splash behavior of the molten pool. To analyze this problem further, a three-dimensional numerical simulation method was used to explore the behavior and change of the flow field inside the molten pool during double-row tuyere injection. In addition, the arrangement of the tuyere was changed for a more detailed understanding of the internal phase distribution and splashing in a molten pool. The results indicated that under three-dimensional numerical simulation conditions, bubbles rise after leaving the tuyere and break on the surface of the molten pool, which results in certain fluctuations in the nearby melt. During the injection process of the tuyere, the meteorological accumulation in the middle part of the molten pool formed part of the foam slag because of the influence of surface tension. When the layout of the upper and lower exhaust tuyeres was changed from staggered to symmetrical, or when the spacing of the upper and lower exhaust tuyeres changed, it had an effect on the phase distribution and splash behavior.

Similar content being viewed by others

References

F. Li, M.S. Chu, J. Tang, Z.G. Liu, Y.S. Zhou, Hebei Metallurgy (2019) No. 10, 8−15.

X.G. Zhang, L.J. Jia, Metallurgy and Materials 39 (2019) No. 4, 90−91.

J.S. Tao, Y.C. Hong, World Metals 2020-01-07 (B02).

A. Yasen, Research on reducing the cost of smelting high-silicon and high-phosphorus COREX molten iron in converter, University of Science and Technology Beijing, Beijing, China, 2019.

J.J. Gao, Pre-reduction of vanadium−titanium magnetite rotary kiln-basic research on full oxygen bath smelting, Central Iron and Steel Research Institute, Beijing, China, 2018.

J.J. Gao, X.Y. Wan, Y.H. Qi, F. Wang, J. Iron Steel Res. 30 (2018) 91−96.

F.H. Liu, S.B. Wang, J.X. Xu, H.T. Wang, H. Wang, J. Kunming Univ. Sci. Technol. (Nat. Sci. Ed.) 40 (2015) No. 1, 60−66.

M.P. Davis, R.J. Dry, M.P. Schwarz, in: Proceedings of the ISS Technology Conference, Indianapolis, USA, 2003, pp. 2−8.

A. Ahmadpour, S.M.A. Noori Rahim Abadi, R. Kouhikamali, Int. J. Multiphase Flow 79 (2016) 31−49.

] P. Buliński, J. Smolka, S. Golak, R. Przyłucki, M. Palacz, G. Siwiec, B. Melka, L. Blacha, Int. J. Heat Mass Transfer 126 (2018) 980−992.

K. Fukagata, N. Kasagi, P. Ua-arayaporn, T. Himeno, Int. J. Heat Fluid Flow 28 (2007) 72−82.

Y.Z. Hou, G.B. Zhang, Y.Z. Qin, Q. Du, K. Jiao, Int. J. Hydrogen Energy 42 (2017) 3250−3258.

W.C. Liu, Numerical simulation of gas−liquid two-phase flow in a smoke furnace, Central South University, Changsha, China, 2014.

H.C. Chuang, J.H. Kuo, C.C. Huang, S.H. Liu, W.S. Hwang, ISIJ Int. 46 (2006) 1158−1164.

D.Y. Yin, W.L. Cheng, J.J. Xie, K.F. Feng, B. Wang, J.Y. Zhang, S.B. Zheng, X. Hong, Chin. J. Process Eng. 10 (2010) 1066−1070.

H.J. Yan, F.K. Liu, Z.Y. Zhang, Q. Gao, L. Liu, Z.X. Cui, D.B. Shen, Chin. J. Nonferrous Met. 22 (2012) 2393−2400.

L.Q. Deng, M.M. Li, Q. Li, Z.S. Zou, J. Mater. Metall. 15 (2016) 25−32.

P. Yan, H.B. Jin, G.X. He, X.Y. Guo, L. Ma, S.H. Yang, R.Y. Zhang, Chem. Eng. Res. Des. 154 (2020) 47−59.

K.J. Vachaparambil, K.E. Einarsrud, Appl. Math. Modell. 81 (2020) 690−710.

L.Y. Wu, L.B. Liu, X.T. Han, Q.W. Li, W.B. Yang, Chin. Phys. B 28 (2019) 104702.

M.Y. Zhu, Z.Z. Cai, H.Q. Yu, J. Iron Steel Res. Int. 20 (2013) No. 3, 6−17.

H.Q. Yu, M.Y. Zhu, ISIJ Int. 48 (2008) 584−591.

J. Anagnostopoulos, G. Bergeles, Metall. Mater. Trans. B 30 (1999) 1095−1105.

B.E. Launder, D.B. Spalding, Comput. Methods Appl. Mech. Engrg. 3 (1974) 269−289.

Acknowledgements

This work was supported by the National Key R&D Program of China (2017YFB0603800 and 2017YFB0603802).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, K., Shen, Yz., Kong, Z. et al. Three-dimensional numerical simulation of flow and splash behavior in an oxygen coal combustion melting and separating furnace. J. Iron Steel Res. Int. 28, 965–977 (2021). https://doi.org/10.1007/s42243-021-00615-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00615-0