Abstract

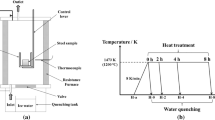

To quantitatively study the mechanism of interfacial reactions between type 430 stainless steel and complex MgO–Al2O3–SiO2–CaO–MnO oxide during the soaking process before hot-rolling, diffusion couple experiments at 1373 K and 1673 K (1100 °C and 1400 °C) with different MnO and SiO2 contents were conducted. Experimental results showed that the “solid–liquid” and “solid–solid” steel–oxide reactions occurred between the Cr, Mn and Si in the steel and the MnO and SiO2 in the MgO–Al2O3–SiO2–CaO–MnO oxide during the heating at 1373 K and 1673 K (1100 °C and 1400 °C), respectively, resulting in a change of steel and oxide compositions. Calculations on the Gibbs free energy changes of those steel–oxide reactions before and after isothermal heating indicated the thermodynamic equilibrium at the interface of the steel and oxide were generally achieved after the heating at 1373 K and 1673 K (1100 °C and 1400 °C) for 240 min. Diffusion coefficients of related elements in type 430 stainless steel at 1373 K and 1673 K (1100 °C and 1400 °C) were calculated: Cr, Mn, and Si at 1673 K (1400 °C) are in the range of 1.44 to 3.40 × 10–12, 0.42 to 1.19 × 10–11 and 0.52 to 1.34 × 10–11 m2 m−1, respectively, while Mn and Si at 1373 K (1100 °C) are in the range of 0.80 to 3.71 × 10−13 and 1.04 to 5.64 × 10−13 m2 s−1, respectively.

Similar content being viewed by others

References

S.K. Gupta, A.R. Raja, M. Vashista, and M.Z.K. Yusufzai: Mater. Res. Express., 2018, vol. 6, art. no. 036516.

L.L. Wei, J.H. Zheng, L.H. Chen, and R.D.K. Misra: Corros. Sci., 2018, vol. 142, pp. 79–92.

L. Tanure, C.M.D. Alcântarac, D.B. Santos, T.R.D. Oliveirac, B.M. Gonzalez, and K. Verbekenb: J. Mater. Res. Technol., 2019, vol. 8, pp. 4048–65.

T.L. Liu, X.F. Zhu, L.J. Chen, H.Y. Bi, Y.F. Lin, and J. Long: J. Mater. Sci., 2019, vol. 55, pp. 3584–99.

Y. Han, J.Q. Sun, Y. Sun, J.P. Sun, and X. Ran: Metals, 2020, vol. 10, art. no. 86.

K.A. Cashell and N.R. Baddoo: Thin. Wall. Struct., 2014, vol. 83, pp. 169–81.

H.J. Bong and J. Lee: Int. J. Mech. Sci., 2021, vol. 191, art. no. 106066.

X.R. Guan, D.L. Zhang, and Y.H. Jin: Appl. Mech. Mater., 2014, vol. 6, pp. 651–53.

F. Shang, X.Q. Chen, P. Zhang, F. Ming, Z.C. Ji, S.B. Ren, and X.H. Qu: Mater. Trans., 2019, vol. 60, pp. 1096–1102.

G. Okuyama, K. Yamaguchi, S. Takeuchi, and K.I. Sorimachi: ISIJ Int., 2000, vol. 40, pp. 121–28.

W.Y. Cha, D.S. Kim, Y.D. Lee, and J.J. Pak: ISIJ Int., 2004, vol. 44, pp. 1134–39.

J.H. Park, D.S. Kim, and S.B. Lee: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 67–73.

J.H. Park and D.S. Kim: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 495–502.

J.H. Park: Calphad, 2011, vol. 35, pp. 455–62.

Z.H. Jiang, S.J. Li, and Y. Li: J. Iron Steel Res. Int., 2011, vol. 18, pp. 14–17.

X. Yin, Y. Sun, Y. Yang, X. Deng, M. Barati, and A. McLean: Ironmak. Steelmak., 2016, vol. 44, pp. 152–58.

Y. Wang, M.K. Oh, T.S. Kim, A. Karasev, W.Z. Mu, J.H. Park, and P.G. Jönsson: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 3815–32.

C. Gu, M. Wang, Y.P. Bao, F.M. Wang, and J.H. Lian: Metals, 2019, vol. 9, pp. 476–91.

Q. Wang, X.D. Zou, H. Matsuura, and C. Wang: Metall. Mater. Trans. B, 2017, vol. 49B, pp. 18–22.

Y.K. Yang, D.P. Zhan, H. Lei, Y.L. Li, X. Liu, Z.H. Jiang, and H.S. Zhang: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1839–53.

A.I. Zaitsev, A.V. Koldaev, A.V. Amezhnov, and N.G. Shaposhnikov: Metallurgist, 2016, vol. 60, pp. 1–9.

Y.X. Zhang, L.F. Zhang, Y.P. Chu, Q. Ren, J.J. Wang, N. Liu, Z.Y. Chen, and J.G. Zhi: Steel Res. Int., 2020, vol. 91, art. no. 2000120.

J. Guo, X.R. Chen, S.W. Han, Y. Yan, and H.J. Guo: Int. J. Min. Met. Mater., 2020, vol. 27, pp. 328–39.

W.L. Gan, C.S. Liu, K. Liao, H. Zhang, and H.W. Ni: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 485–502.

H. Mehrer: Diffusion in Solids: Fundamentals, Methods, Materials, Diffusion-Controlled Processes, Springer, Berlin, 2007.

Acknowledgments

The current study was supported by the National Natural Science Foundation of China (Grant Nos. 52074198, 51774217 and 51604201).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gan, W., Liu, C., Liao, K. et al. Mechanism of Interfacial Reactions Between Type 430 Stainless Steel and Complex MgO–Al2O3–SiO2–CaO–MnO Oxide During Isothermal Heating. Metall Mater Trans B 53, 2553–2569 (2022). https://doi.org/10.1007/s11663-022-02551-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02551-0