Abstract

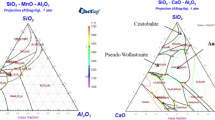

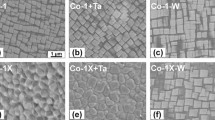

In this work, a direct alloying technology of molten steel by the self-reduction briquette composed of vanadium slag and graphite powder was proposed. The reduction behavior of vanadium slag briquette was thermodynamically and experimentally investigated, and relevant reaction mechanisms were discussed. The results show that the increases in C/O molar ratio and reduction temperature would promote the further reduction of vanadium slag. The reduction degrees of FeO, Cr2O3, MnO, and V2O5 increased from 85.24, 47.98, 9.05, and 75.70 pct to 92.10, 64.53, 42.52, and 79.62 pct, respectively, with increasing temperature from 1500 °C to 1600 °C. As the C/O molar ratio increased from 0.8 to 1.2, the reduction degrees of FeO, Cr2O3, MnO, and V2O5 sharply increased from 86.56, 18.38, 43.38, and 50.91 pct to 92.10, 64.53, 50.02, and 79.62 pct, respectively, and then slowly increased or nearly remained constant. The briquette basicity exhibits an obvious positive influence on the reduction of vanadium slag to a certain extent, and the reduction degrees of FeO, Cr2O3, MnO, and V2O5 increase from 92.10, 64.53, 42.50, and 76.14 pct to 97.21, 81.04, 75.64, and 88.50 pct with increasing the basicity from 0 to 0.5, leading to a significant decrease in the reduction degree of vanadium slag when the basicity increased from 0.5 to 1.5. For the hybrid reductant of aluminum dross and graphite powder, when the proportion of aluminum dross exceeds 52 pct, a considerable amount of solid compound (magnesia-alumina spinel) would be precipitated from liquid slag, which strongly affects the thermophysical properties of molten slag. Under the optimal conditions, C/O molar ratio of 1.2, reduction temperature of 1600 °C, and briquette basicity of 0.5, the reduction degrees of FeO, Cr2O3, V2O5, and MnO could reach the maximum of 97.21, 81.04, 88.50, and 75.64 pct, respectively, and a crude Fe–V alloy mixture containing 23.40 pct V could be obtained.

Similar content being viewed by others

References

O. Nokhrina, I. Rozhikhina, V. Dmitrienko, M. Golodova, and Y.A. Osipova: Steel Transl., 2015, vol. 45, pp. 543–45.

H. Antrekowitsch, S. Luidold, and H. Gaugl: BHM, 2008, vol. 153, pp. 109–15.

O. Nokhrina, I. Rozhikhina, V. Dmitrienko, M. Golodova, and Y.A. Efimenko: Steel Transl., 2014, vol. 44, pp. 99–102.

J. Zhang, W. Zhang, L. Zhang, and S. Gu: Int. J. Min. Process., 2015, vol. 138, pp. 20–29.

L. Chen, J. Diao, G. Wang, and B. Xie: JOM, 2018, vol. 70, pp. 963–68.

A. Teng and X. Xue: J. Haz. Mater., 2019, vol. 379, p. 120805.

Z.F. Yuan, W.L. Huang, S.Y. Zhu, D.H. Liao, and H.F. Hu: Steel Res. Int., 2002, vol. 73, pp. 428–32.

X. Hu: Steel Res. Int., 2016, vol. 87, pp. 1–7.

J. Madias: in ABM Week—50th ABM Steelmaking Sem., Sao Paulo, Brazil, Oct. 2018, pp. 1–3.

S. Song, Z. Xue, B. Zhang, W. Wang, R. Liu, and G. Wang: Ironmak. Steelmak., 2014, vol. 41, pp. 7–11.

X. Hu, L. Sundqvist, Q. Ökvist, B. Yang, and B. Björkman: Ironmak. Steelmak., 2015, vol. 42, pp. 409–17.

A. Ahmed, M.K. El-Fawakhry, M. Eissa, and S. Shahein: Ironmak. Steelmak., 2015, vol. 42, pp. 648–55.

J. Xin, N. Wang, M. Chen, and C. Chen: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 815–29.

S.Q. Song, Z.L. Xue, Y.U. Yue, R.N. Liu, and G.L. Wang: ISIJ Int., 2013, vol. 53, pp. 1138–42.

S.Q. Song, Z.L. Xue, W.X. Wang, P. Li, R.N. Liu, and G.L. Wang: Met. Int., 2012, vol. 17, pp. 83–85.

B. Zhang, Z.L. Xue, T.T. Zhu, and J. Dong: J. Iron Steel Res. Int., 2015, vol. 22, pp. 402–07.

Z. Hung and L. Zheng: J. Iron Steel Res. Int., 2013, vol. 21, pp. 51–56.

M. Divakar, M. Görnerup, and A. Kumar Lahiri: Steel Res. Int., 2001, vol. 72, pp. 40–43.

B. Zhang and C. Wei: Iron Steel Vanad. Titan., 1991, vol. 12, pp. 25–29. (in Chinese).

A. Roine: Chemical Reaction and Equilibrium Software with Extensive Thermo-Chemical Database, Outokumpu HSC 6.0, Outotec Oy Research Center, Pori, Finland, 2010.

Z. Guo, D. Zhu, J. Pan, and F. Zhang: J. Clean. Prod., 2018, vol. 187, pp. 910–22.

K. Morita, M. Mori, M. Guo, T. Ikagawa, and N. Sano: Steel Res. Int., 1999, vol. 70, pp. 319–24.

R. Inoue and H. Suito: J. Iron Steel Inst. Jpn., 1982, vol. 68, pp. 1532–40.

J. Xin, N. Wang, M. Chen, and C. Chen: ISIJ Int., 2020, vol. 60, pp. 823–31.

M. Mahinroosta and A. Allahverdi: J. Environ. Manag., 2018, vol. 223, pp. 452–68.

J.H. Heo, T.S. Kim, V. Sahajwalla, and J.H. Park: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1201–10.

S. Hamar-Thibault, L. Adnane, and R. Kesri: J. Alloys Compd., 2001, vol. 317, pp. 311–14.

W. Huang: Metall. Trans. A, 1991, vol. 22A, pp. 1911–20.

J.H. Heo, Y. Chung, and J.H. Park: J. Clean. Prod., 2016, vol. 137, pp. 777–87.

J.H. Heo and J.H. Park: Calphad, 2017, vol. 58, pp. 219–28.

Acknowledgments

The authors gratefully acknowledge the National Natural Science Foundation of China (Grant Nos. 51774073, 51974080, and 52074077). The Fundamental Research Funds for the Central Universities was supported by the Chinese Education Ministry (Grant No. N2125018).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xin, J., Wang, N., Chen, M. et al. Direct Alloying of Molten Steel with Vanadium Slag: Self-reduction of Vanadium Slag Briquette with Graphite Powder and Hybrid Reductant of Graphite Powder-Aluminum Dross. Metall Mater Trans B 53, 2334–2348 (2022). https://doi.org/10.1007/s11663-022-02532-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02532-3