Abstract

The experimental study of the phase equilibria between calcium ferrite slag, metallic copper, spinel and/or dicalcium ferrite in the Cu2O-FeOx-CaO system has been carried out. Effects of temperature, oxygen partial pressure and Fe/CaO ratio on phase assemblages and compositions have been estimated. The advanced experimental technique including high-temperature equilibration on primary phase substrates, rapid quenching of the samples and quantitative measurements of equilibrated phase compositions using electron probe X-ray microanalysis has been applied. Spinel and dicalcium ferrite substrates have been specially designed to study phase equilibria at certain primary phase fields. Obtained experimental results have been compared with thermodynamic assessment of the Cu2O-FeOx-CaO system and available literature data.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Processes of continuous copper converting to blister copper are being actively developed nowadays using alternative ways of copper production instead of traditional Pierce–Smith converters. Outotec flash converting,[1] ISACONVERT™ process[2] and Mitsubishi process[3] can be listed as modern and advanced examples. All these processes are operated at quite high oxygen pressure close to spinel liquidus and fluxed with CaO–containing agents, resulting in formation of calcium ferrite slags with high copper concentrations (up to 25 wt pct). Calcium ferrite slags are characterised by many advantages over conventional iron-silicate slags. Low slag volumes, low viscosity, high fluidity, more efficient removal of copper and side impurities at further cleaning processes are among of these advantages. For effective development and optimisation of the processes operating with calcium ferrite slags the fundamental information about phase equilibria in the quaternary Cu-Ca-Fe-O system is highly important.

Despite the practical relevance of the Cu-Ca-Fe-O system the phase equilibria at variable oxygen partial pressure have not been studied extensively. Possible reasons of scarce experimental data are methodological difficulties occurring at equilibration and quenching of calcium ferrite slags. In particular, interaction of slag with many conventional crucible materials (CaO, MgO) and quenching issues make it difficult to obtain accurate quantitative results of the phase equilibria. However, some experimental studies put the foundation for further development of the calcium-ferrite slags research. Yazawa et al.[4] published a pioneer study of phase equilibria between copper and calcium ferrite slags at 1150 °C to 1350 °C and wide range of P(O2) from 10−12 to 10−5 atm. Lime or magnesia crucibles were used for equilibration of the mixtures. It was reported that solubility of MgO in slag did not exceed 3 wt pct. Later, it was shown that MgO affects copper solubility and Fe3+/Fe2+ ratio in slag.[5] The liquidus projection of the CaO-FeOx-Cu2O system in equilibrium with metallic copper has been plotted by Takeda et al.[6] using the data of equilibration experiments in MgO crucibles followed by chemical analysis of obtained samples. The temperatures of invariant reactions were defined by thermal analysis in that paper. Dissolution of minor elements (As, Bi, Cu, Ni, Pb) in calcium ferrite slags at 1250 °C in lime crucibles was measured by Eerola et al.[7] under nitrogen gas flow. Effect of oxygen potentials on the equilibria between copper-gold alloys and - calcium ferrite slags was estimated by Palacios and Gaskell in Reference 8 at 1300 °C and P(O2)s = 10−10 to 10−7 atm using CaO crucibles. Copper solubility in calcium ferrite slags using MgO crucibles was investigated by Somerville et al. at 1300 °C and P(O2)s = 10−11 to 10−5 atm.[9] Employing ceramic (MgO, CaO) crucibles in all mentioned studies resulted in contamination of the slag phase with side elements and reducing the quenching rates. Extensive studies of calcium ferrite slags in equilibrium with copper have been carried out at Pyrosearch Innovation centre.[10,11,12,13] Ilyuchechkin et al.[10] studied the compositional changes in the Cu2O-FeOx-CaO system during the equilibration process, examined different shapes and materials of the substrates to ensure successful equilibration and quenching processes, and used a levitation technique to obtain a completely homogeneous liquid slag. The results obtained using levitation and “primary phase substrate” techniques were consistent with each other and proved the possibility of producing the accurate experimental results without contaminations of container materials at quite high quenching rates. The “primary phase substrate technique” was applied for experimental study and plotting of pseudo-binary phase diagrams of the Cu2O-“Fe2O3” and Cu2O-CaO systems in equilibrium with metallic copper.[12] Isothermal sections of the Cu2O-“Fe2O3”-CaO system in equilibrium with metallic copper at 1200 °C and 1250 °C[13] have been plotted based on results of seven successful experiments. Detailed analysis of oxygen potential effect on copper solubility in calcium ferrite slags has not been studied yet. Thermodynamic assessment of the CaO-Cu2O-FeO-Fe2O3 system was performed by Shishin et al.[14] based on critical evaluation of available experimental data. The discrepancies between the calculation and experimental results were identified.

The aim of this study is to estimate the effects of temperature, oxygen partial pressure and Fe/CaO ratio on the phase equilibria between calcium ferrite slags and copper using the improved “primary phase substrate” technique. The obtained results will allow the authors to test the thermodynamic model reported earlier[14] and to eliminate the indicated experimental discrepancies.

Experimental Part

The experimental methodology is based on the technique published in the papers[10,13] and adopted in the present study using the new types of primary substrate materials. It includes high-temperature equilibration of the samples on a specially designed primary phase substrates made from spinel or Ca2Fe2O5 in a vertical tube furnace under controlled gas atmosphere, rapid quenching in 20 pct CaCl2 brine solution at − 20 °C, metallographic preparation of the samples, and direct measurement of the compositions of the equilibrium phases with the electron-probe X-ray microanalysis (EPMA).

The initial mixtures were prepared from preliminary melted “master slag”, Fe2O3 (99.9 wt pct purity) and Cu powder (99.9 wt pct purity) supplied by the Alfa Aesar Company, thoroughly mixed and pelletised for better contact between the species. A master slag of Ca48Fe52O126 composition was prepared by melting precalcined CaCO3 and Fe2O3 in Pt crucible at 1300 °C for 2 hours in muffle furnace. The structure and composition of produced master slag was examined by EPMA and having stoichiometry close to dicalcium ferrite (Ca2Fe2O5). The compositions of the initial mixtures were calculated using FactSage software[15] and internal database[16,17] updated for calculation of phase equilibria in calcium ferrite slags in a result of thermodynamic optimisation published in Reference 14. The ratios of the components in the mixtures were selected to get the slag/copper/spinel or slag/copper/ Ca2Fe2O5 phase equilibria at given temperature and oxygen partial pressure. The calculated volume ratio of the primary solid phase was minimised as substrates phases also participate in phase reactions and can dissolve or crystallise from the slag. The slag/copper initial ratio in the mixtures varied according to the selected oxygen partial pressure as amount of metallic copper is expected to be lower due to the processes of copper oxidation and dissolution in slag at equilibration. The main reaction affecting on resulted phase ratio is expected to be copper oxidation and dissolution in slag phase, therefore, initial ratio of copper metal to components of slag phase should be increased with increasing of oxygen partial pressure in the system. Resulted phase ratio after equilibration process was predicted using FactSage software[15] and internal database.[16,17] The compositions of the initial mixtures, the experimental conditions (type of substrate, temperatures, oxygen partial pressure, and gas flow ratios) as well as predicted phase ratios are listed in Table I.

Two types of substrates were designed to support the samples in the present study. High purity Fe3O4 (spinel) was used for equilibration samples in spinel primary crystallisation phase field and Ca2Fe2O5 substrate was used in dicalcium ferrite primary crystallisation phase field. It should be noted that other types of substrates were tested in preliminary experiments: magnesia crucible, zirconia crucible, platinum, and iridium wires. It was observed that MgO and ZrO2 crucibles interacted with the slag during the equilibration process. In particular, it was measured by EPMA that 2.3 to 2.4 wt pct of MgO and 2.0 to 2.1 wt pct of ZrO2 were dissolved in the slag phase. It was analysed using EPMA that zirconium and magnesium oxides also formed a solid intermediate layers between the slag and the crucible. Pt and Ir wires reacted with copper and formed copper alloys, thus decreasing the activity of copper metal and the solubility of copper in the slag phase. Table II illustrates the effect of the substrate material (Pt wire vs spinel substrate) on copper composition and copper solubility in slag phase. Two pairs of consequent experiments were carried out under the same conditions (initial mixture, temperature, oxygen partial pressure) but using different substrate materials. It is shown in Table II that Pt interacts with copper to form a CuPt alloy and decreases the activity of copper in slag phase (see experiments ## 2 and 3). As a result, copper concentration in slag phase obtained on Pt wire is lower than on spinel substrate under the same experimental conditions.

Thus, it is assumed that only substrates prepared from the primary phases (spinel or dicalcium ferrite) are suitable for equilibration experiments and produce accurate quantitative results unaffected by crucible materials and quenching difficulties.

The spinel substrate was prepared from the 99.9 wt pct pure iron foil (supplied by Goodfellow Cambridge Ltd., Huntingdon, England) folded into the required shape and then oxidized at 1200 °C for 2 hours using pure CO2 gas with oxygen partial pressure corresponding to p(O2) = 10−3.9 atm. Based on the previous assessment of the Fe-O system, obtained spinel is expected to have a composition close to stoichiometric Fe3O4.[18] Several different shapes of spinel substrates were tested. The final substrate shape was adopted in the form of a basket with open ends (Figure 1(a)).

The Ca2Fe2O5 substrate was prepared from the mixtures of pure CaCO3 and Fe2O3 oxides by sintering. Powder mixtures were pelletised in specially designed press-form of cone shape and cold moulding technique was applied to the initial substances. Then the substrates were sintered at 1200 °C for 5 hours in air. The photo of substrate in accepted conical form is given in Figure 1(b).

The average mass of the sample depends on the type of substrate, as it is very important to keep the optimal mass ratio between the sample and substrate in order to avoid the drop of substrate during high temperature equilibration, especially in the case of Ca2Fe2O5 substrate. Thus, the mass of the sample on spinel substrate was about 100 mg (substrate/sample mass ratio was 2/1); the mass of the sample on Ca2Fe2O5 substrate varied from 50 to 70 mg (substrate/sample mass ratio was 5/1).

The substrate loaded with the sample was suspended in a uniform hot zone of the furnace at a fixed temperature. Before starting the equilibration process the temperature was raised by 20 °C above the equilibration temperature for 15 minutes then lowered back to the selected temperature. The Ir wire (99.9 wt pct purity, supplied by Alfa Caesar) was used to suspend both types of substrates in the furnace. A calibrated, alumina-shielded Pt/Pt-Rh 13 pct thermocouple was placed immediately adjacent to, but not touching the sample to monitor the actual sample temperature. The thermocouple was calibrated against a standard thermocouple (supplied by the National Measurement Institute of Australia, NSW, Australia). Digital 4-channel multimeter TM-947SD manufactured by Lutron electronic (Taiwan) with data logger from SD card was connected to thermocouple for temperature measurement. The accuracy of the temperature measurement was estimated to be within 5 °C.

The oxygen partial pressure was maintained by accurate control of the CO and CO2 ratio in the gas phase using a system of calibrated U-tube capillary flow-meters. The desired gas flowrates to achieve the selected conditions were calculated using FactSage 7.3 software and FactPS database for ideal gas phases and given in Table I. The accuracy of the oxygen potentials was confirmed using a separate vertical tube furnace equipped with a DS-type oxygen probe (supplied and calibrated by Australian Oxygen Fabricators, AOF, Melbourne, Australia) at the same temperature as in the experiments. Calculated difference between expected and actually measured logP(O2) did not exceed 0.1 .It means, if particular, that observed logP(O2) = 10−7.1 atm corresponds to targeted logP(O2) = 10−7.0 atm.

As it was mentioned earlier, the calcium ferrite slags are characterised by a rather low viscosity, and the diffusion rates in these slags are much higher compared to fayalite-based slags. Preliminary experiments were performed at 1200 °C and P(O2) = 10−6 atm to test different equilibration times ranged from 0.5 to 24 hours. The compositions of the slag phases measured by EPMA were found to be the same in all experiments with an accuracy of 1 rel. pct without any particular trend of composition variation over time. Other authors claimed that equilibration for one hour is enough to reach the equilibrium.[19] In the present study, an equilibration time of 3 hours was selected to ensure obtaining the equilibrium phases under given conditions (temperature and oxygen partial pressure). After equilibration, the samples were quenched and metallographically prepared for further studies using optical microscopy and electron probe microanalysis.

Direct measurement of the equilibrium phase compositions was undertaken by electron probe X-ray microanalysis (EPMA) using the JEOL JXA 8200L probe (trademark of Japan Electron Optics Ltd., Tokyo) at an acceleration voltage of 15 kV and a probe current of 20 nA. Appropriate reference materials from Charles M. Taylor, Stanford, CA were used as standards. Copper, iron and oxygen concentrations in metal phase were measured and calibrated against pure Cu and Fe metals and O concentration in Fe2O3. The Cu, Fe and Ca concentrations in slag phase were defined against pure Cu, Fe2O3 and CaSiO3 standards. At least three representative areas with all quenched phases in equilibrium were selected for each sample. At least ten points for each phase (copper, slag, spinel or dicalcium ferrite) were used for composition measurements in selected areas to get representative number of points. For some areas of slag phase, line analysis was performed to check a possible trend of composition changing. The size of copper phase varied from 5 to 500 µm, only particles larger than 30 µm were employed for analysis, as smaller phases could potentially precipitate during quenching. An example of selected points for measurement is given in Figure 2. A non-zero probe diameter has been implemented to provide improved accuracy of phase compositions measurements, particularly in the case of microstructures that exhibit inhomogeneous areas as a result of mass transfer taking place during quenching from an equilibration temperature. A detailed analysis of the probe diameter effect on average phase compositions and standard deviation was published in Reference 20. Based on this analysis and preliminary measurements, the probe diameters of 50 and 10 µm were selected for slag and copper phases, respectively. The time of signal collection from peak and from background was 40 to 50 and 6 to 8 seconds. respectively, based on the predicted elemental concentration in the phase. The Duncumb–Philibert ZAF correction procedure supplied with the JEOL JXA 8200L probe was applied to the data obtained. The additional correction of slag composition was applied after the standard ZAF correction, following an approach described in paper.[21] Then the average elemental concentration and standard deviation were calculated for each presented phase of the experiment.

It should be noted that the elemental concentrations are measured by EPMA, and then they can be recalculated to the selected oxidation states for the slag and solid oxides phases. As copper and iron are characterised by different oxidation states in calcium ferrite slags, and the Fe3+/Fe2+ and Cu1+/Cu2+ ratios depend on oxygen potential in the system, the measured metal concentrations were used to unambiguously report the compositions of the phases. All elemental concentrations in slag were then recalculated to selected oxidation states of Cu+ and Fe3+ for presentation purposes only.

Results and discussion

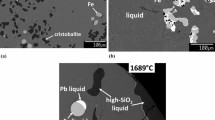

Examples of the microstructures of the equilibrated samples on spinel (a) and on Ca2Fe2O5 substrate (b) are shown in Figure 3. It is shown in Figure 3(a) that calcium ferrite slag is not fully homogeneous, therefore, using non-zero probe diameter for measurement of slag phase composition is justified. The crystals of dicalcium ferrite are spreaded within the slag phase on the right image (Fig 3(b)).

Table III summarizes the measured compositions of the phases under the selected conditions and at 3 hours equilibration time. The concentrations of elements in phases below EPMA detection limit (for instance, Cu concentration in Ca2Fe2O5 or oxygen and iron concentration in metallic copper) are indicated by symbol BDL. Some experiments were repeated under the same conditions to show the repeatability of the obtained results. It is shown that the results of the experiments # 1, 2 and 3 (at 1200°C, P(O2) = 10−7 atm, on a spinel substrate), also 7, 8 and 9 (at 1200 °C, P(O2) = 10−6 atm, on a Ca2Fe2O5 substrate) are reproduced within the experimental accuracy, that proves the adequacy and reliability of the applied experimental technique.

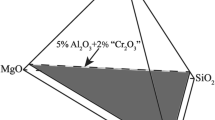

The measured compositions of slag and solid oxide phases (spinel or dicalcium ferrite) were recalculated to mol. fractions with equal number or metal cations (to unambiguously report the metal ratio in the system) and plotted on isothermal projections at 1200 °C, 1250 °C and 1300 °C accordingly (Figure 4). The isothermal projections were plotted as a result of thermodynamic calculation using FactSage 7.3[15] and internal database after optimisation described in Reference 14. Boundaries of liquid slag and tie-lines with spinel or dicalcium ferrite phases are illustrated. Experimental points and tie-lines, obtained in the current study and adopted from available original researches[6,10,13,19,22] are labelled by symbols.

Isothermal projections of the CuO0.5-FeO1.5-CaO system in equilibrium with copper through the oxygen corner at 1200 (a, d), 1250 (b, e) and 1300 °C (c, f). Zoomed images (d, e, f) are presented to identify the compatibility of obtained experimental results, calculated trends and literature data.[6,10,13,19,22]

It is shown that at 1200 °C compositions of the liquid slags in equilibrium with spinel and dicalcium ferrite are in good agreement with data by Ilyuchechkin,[10] and calculated lines. For isothermal projection at 1250 °C the CaO concentration in the liquid slag in equilibrium with spinel and dicalcium ferrite has a tendency to increase in comparison with literature data and calculation results. At 1300 °C the obtained experimental results confirm the calculated trends, but are higher in CaO concentrations than the results published in Reference 6. The mentioned difference can be explained by the fact that slag compositions reported by Takeda et al. contained 1 to 3 wt pct MgO due to dissolution of magnesia crucible which could affect the results.

The solubility of copper in slag at different oxygen potentials is illustrated in Figure 5 at 1200 °C, 1250 °C and 1300 °C respectively. The overall tendency of reducing the copper concentration in slag with decreasing in oxygen partial pressure is observed at all temperatures. At a fixed oxygen partial pressure the copper losses in slags in equilibrium with spinel and dicalcium ferrite are very similar at all temperatures. The experimental accuracy does not allow detection any trend of copper solubility in slag depending on Fe/CaO ratio at 1200 °C and at 1250 °C (Figure 4(a), (b)). The detectable effects are observed only at 1300 °C (Figure 4(c)). Comparison with literature data showed that at 1200 °C copper concentration in slag at fixed oxygen partial pressure is in good agreement with data of Zhao et al.,[22] but lower than the results published in Reference 19 in equilibrium with dicalcium ferrite. At 1250 °C the experimental results are in good consistency with Takeda’s data[6] at P(O2) = 10−7 and 10−6 atm, but higher than the data reported in Reference 4 at P(O2) = 10−5 atm. And at 1300 °C there is a good agreement between the measured copper losses in slag and data of Somerville et al.[9] but a contradiction with higher values reported by Eerola et al.[7] The discrepancies can be explained by the fact that the slag compositions reported in Reference 7 contain 1-3 wt pct SiO2 and small amounts of Ni, Sb, As, Pb and Al.

Based on measured results of copper concentration in the slag phase at fixed temperature and oxygen partial pressure the activity of liquid CuO0.5 in the slag phase was calculated and illustrated in Figure 6. It can be seen from Figure 6 that the results obtained on copper activity in the slag are in good agreement with data of References 6, 19, and 22.

Application

The effect of the Fe/CaO ratio on copper concentration in slag is illustrated in Figure 7. The experimental points are plotted along with the results of thermodynamic optimisation[14] illustrating isotherms at 1200 °C to 1300 °C. When the copper concentration in slag is from 1 to 25 wt pct the liquid slag is in equilibrium with spinel phase or with dicalcium ferrite phase depending on the Fe/CaO ratio. The region of liquid slag becomes narrower with decreasing temperature limiting the change of Fe/CaO ratio. This graph can be used for optimization of smelting and converting processes. For instance, for stable operation at 1200 °C at spinel liquidus it is necessary to obtain 10 wt pct copper in slag and Fe/CaO ratio about 2.3. If this is not possible due to technological or economical limitations, the process temperature should be increased to1250 °C.

Slag liquidus in the CaO-Cu2O- FeOx system in equilibrium with copper. Lines are calculated using thermodynamic model,[14] symbols are experimental data

Conclusions

Experimental study of the copper/slag/spinel or dicalcium ferrite phase equilibria in the Cu2O-FeOx-CaO system in equilibrium with metallic copper has been carried out. The improved experimental technique has been applied for experiments implementation. The effects of temperature, oxygen partial pressure and Fe/CaO ratio on the phase equilibria have been evaluated. The obtained results have been compared with calculated trends and available literature data. Comparison of the results confirmed the reliability and accuracy of the thermodynamic optimisation performed for this system. The obtained results will be used for further thermodynamic optimisation of the phase equilibria in the Al-Ca-Cu-Fe-Mg-Pb-Zn-O-S-Si multicomponent system and for calculation phase equilibria relevant to copper, lead and zinc production.

References

R. Kaur, C. Nexhip, D. Krippner, D. George-Kennedy and M. Routledge, In 13th International Flash Smelting Congress (Zambia, 2011).

S. Nikolic, J.S. Edwards, A.S. Burrows and G.R.F. Alvear, In Int. Peirce-Smith Converting Centen., ed. Joel Kapusta and Warner Tony (Minerals, Metals & Materials Society, Warrendale, PA: 2009), pp 407–14.

F. Tanaka, O. Iida and Y. Takeda: Metall. Mater. Process. Princ. Technol. Yazawa Int. Symp. 2003, vol. 2, pp. 495–508.

A. Yazawa and Y. Takeda: Trans. Jpn. Inst. Met., 1982, vol. 23(6), pp. 328–33.

D. Shishin, T. Hidayat, A. Fallah Mehrjardi, P.C. Hayes, S.A. Decterov, and E. Jak: J. Phase Equilib. Differ., 2018, vol. 40, pp. 445–61. https://doi.org/10.1007/s11669-019-00716-0.

Y. Takeda, In Metall. Mater. Process.: Princ. Technol., Yazawa Int. Symp., (Minerals, Metals & Materials Society, Warrendale, PA: 2003), pp 211-225.

H. Eerola, K. Jylha, and P. Taskinen: Trans. Inst. Min. Metall. Sect. C., 1984, vol. 93, pp. 193–99.

J. Palacios and D.R. Gaskell: Metall. Trans. B., 1993, vol. 24B(2), pp. 265–69. https://doi.org/10.1007/bf02659128.

M. Somerville, S. Sun, and S. Jahanshahi: Metall. Mater. Trans. B., 2014, vol. 45(6), pp. 2072–79. https://doi.org/10.1007/s11663-014-0157-1.

A. Ilyushechkin, P.C. Hayes, and E. Jak: Metall. Mater. Trans. B., 2004, vol. 35B(2), pp. 203–15.

S. Nikolic, P.C. Hayes, and E. Jak: Metall. Trans. B., 2008, vol. 39B(2), pp. 200–09. https://doi.org/10.1007/s11663-008-9128-8.

S. Nikolic, P.C. Hayes, and E. Jak: Metall. Mater. Trans. B., 2009, vol. 40B(6), pp. 892–99.

S. Nikolic, P.C. Hayes, and E. Jak: Metall. Mater. Trans. B., 2009, vol. 40B(6), pp. 900–09.

D. Shishin, T. Hidayat, and E. Jak: Calphad., 2019, vol. 68, 101715. https://doi.org/10.1016/j.calphad.2019.101715.

C.W. Bale, E. Belisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.H. Jung, Y.B. Kang, J. Melancon, A.D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, and M.A. Van Ende: Calphad., 2016, vol. 54, pp. 35–53. https://doi.org/10.1016/j.calphad.2016.05.002.

D. Shishin, P.C. Hayes and E. Jak, In Extraction 2018, ed. B. Davis, Moats M. and Wang S. (Springer: Ottawa, Canada, 2018), pp 853–68.

E. Jak, T. Hidayat, D. Shishin, V. Prostakova, M. Shevchenko and P.C. Hayes, In 58th Annual Conference of Metallurgists Copper'2019, (MetSoc: Vancouver, Canada, 2019), p 595879.

T. Hidayat, D. Shishin, E. Jak, and S. Decterov: Calphad., 2015, vol. 48, pp. 131–44. https://doi.org/10.1016/j.calphad.2014.12.005.

S. Nikolic, P.C. Hayes, and E. Jak: Metall. Mater. Trans. B., 2009, vol. 40B(6), pp. 910–19. https://doi.org/10.1007/s11663-009-9295-2.

S. Sineva, M. Shevchenko, P.C. Hayes, and E. Jak: Miner. Process. Extract. Metall. Rev., 2021, https://doi.org/10.1080/08827508.2021.1998042.

M. Shevchenko and E. Jak: J. Phase Equilib. Differ., 2019, vol. 40, pp. 128–37. https://doi.org/10.1007/s11669-018-0703-7.

B. Zhao, E. Jak, P. Hayes, J. Font and A. Moyano, In MOLTEN 2009, ed. Mario Sanchez (GECAMIN: Santiago, Chile, 2009), pp. 225–35.

Acknowledgments

The authors would like to thank Australian Research Council Linkage program, Anglo American Platinum, Aurubis AG, BHP Olympic Dam Corporation, Boliden, Glencore Technology, Kazzinc Glencore, Nyrstar, Outotec Oy, Peñoles, RHI Magnesita, Kennecott Rio Tinto and Umicore NV for the financial and technical support for this study. The authors would like to thank the staff of the Centre for Microscopy and Microanalysis, University of Queensland for technical support.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sineva, S., Shishin, D., Starykh, R. et al. Experimental Study of the Cu2O-FeOx-CaO System in Equilibrium With Metallic Copper at 1200 °C to 1300 °C and at P(O2)s = 10−5 to 10−7 Atm. Metall Mater Trans B 53, 2293–2302 (2022). https://doi.org/10.1007/s11663-022-02529-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02529-y