Abstract

Argon gas injection into a continuous casting mold (vessel with moving liquid) helps in increasing the casting sequence length by avoiding SEN clogging. Bubble formation may create bubble-related steel defects at specific operating conditions. Parametric estimation of bubble size distribution (BSD) and mean bubble diameter may identify the type of unforeseen defect in cast slab. Physical modeling experiments were performed to estimate Sauter mean diameter (SMD) of the bubbles for different input parameters such as gas/liquid flow rates and liquid properties. High-speed high-resolution imaging and advanced image processing were used to capture images from the physical model. Four different simulating liquids were used in the physical modeling experiment. Bubble characteristic data were used to measure the SMDs (output data). Different values of SMDs were correlated with the input parameters using direct multilinear regression (DMR). Experimental and predicted values were found well in agreement with high R2. A dimensionless equation was also determined using the same data and compared with the DMR correlation. DMR correlation was compared and validated with the previous work related to the bubbly flows in stagnant and moving liquid flow regimes. As a result, it was concluded that an increasing gas flow rate, a decreasing liquid flow rate, an increasing surface tension, and an increasing viscosity increase the SMD of bubbles formed in the mold.

Similar content being viewed by others

Abbreviations

- F g :

-

Gas fraction in liquid

- Q L :

-

Liquid flow rate

- Q G :

-

Gas flow rate

- d 32 :

-

Sauter mean diameter of the bubbles

- d i :

-

Diameter of ith bubble

- n i :

-

Number of ith bubble diameter (same bubble diameter)

- b :

-

Coefficient of lnQL

- σ :

-

Surface tension of the liquids

- µµ L :

-

Viscosity of the liquid

- ρ L :

-

Density of the liquid

- H :

-

Submerge Depth of the Submerged Entry Nozzle

- λ :

-

Scale Factor, Dimension of model/dimension of prototype mold (real mold)

- Q Liquid- n :

-

Liquid flow rate for nth liquid

- ρ Liquid - n :

-

Density of Liquid-n

- d ni :

-

Internal Diameter of the injection nozzle

- d o :

-

Outer Diameter of the injection nozzle

- D :

-

Diameter of the bubble column (Akita and Yoshida)

- d n :

-

Nozzle diameter (Sada et al.)

- u g :

-

Gas velocity (Sada et al.)

- u l :

-

Liquid velocity (Sada et al.)

- f :

-

Bubble detachment function (Luty and Pronczuk)

- b :

-

Ratio of major to minor bubble diameter

- D h :

-

Diameter of gas injection hole

- T :

-

Temperature of liquid

- Regas :

-

Reynolds number of gas

- Reliq :

-

Reynolds number of liquid

- µ g :

-

Viscosity of gas

- d :

-

Nozzle diameter of gas injection port

- U :

-

Liquid velocity

References

B. Thomas, A. Dennisov, and H. Bai, in Proc. of ISS Steelmaking Conf., Chicago 1997, 80, pp. 375–84

C. C. Maier, U. S. Bur. Mines Bull., 1927, No. 260, p. 62

T. Tadaki and S. Maeda: Chem. Eng., 1963, vol. 27, pp. 147–55. https://doi.org/10.1252/kakoronbunshu1953.27.147.

L. Davidson and E.H. Amick Jr.: AIChE J., 1956, vol. 2, pp. 337–42. https://doi.org/10.1002/aic.690020309.

I. Leibson, E.G. Holcomb, A.G. Cacoso, and J.J. Jamic: AIChe J., 1956, vol. 2, pp. 300–06.

A. Mersmann, VDI-Forschllngshift 491, 1962, Vol. 28B, pp.1–39

M. Sano, K. Mori, and T. Sato: Tetsu-to-Hogane., 1974, vol. 60, pp. 348–60.

K. Akita and F. Yoshida: Ind. Eng. Chem. Process Des. Dev., 1974, vol. 13(1), pp. 84–90.

M. Sano and K. Moil: Trans. JIM (Japan)., 1976, vol. 17, pp. 344–52.

A. Kumar, T.E. Degaleesan, G.S. Laddha, and H.E. Hoelscher: Can. J. Chem. Eng., 1976, vol. 54, pp. 503–08.

M. Iguchi, T. Chiara, N. Takanashi, Y. Ogawa, N. Tokumitsu, and Z. Morita: ISIJ Int., 1995, vol. 35, pp. 1354–61.

R. Pohorecki, W. Moniuk, P. Bielski, P. Sobieszuk, and G. Dabrowiecki: Chem. Eng. J., 2005, vol. 113, pp. 35–39. https://doi.org/10.1016/j.cej.2005.08.007.

G.A. Irons and R.I.L. Guthrie: Metall. Trans. B, 1978, vol. 9B, pp. 101–10.

K. Mori, M. Sano, and T. Sato: Trans. ISIJ, 1979, vol. 19, pp. 553–58.

M. Iguchi, T. Chihara, N. Takanashi, Y. Ogawa, N. Tokumitsu, and Z. Morita: ISIJ Int., 1995, vol. 35, pp. 1354–61.

K. Akita and F. Yoshida: Ind. Eng. Chem. Proc. Des. Dev., 1974, vol. 13, pp. 84–91.

L. L. van Dierendonck, Ph.D. Thesis, Chapter 2, University Twente, 1970

P. Bielski, Ph.D. Thesis, Warsaw University of Technology, 2002

G.A. Hughmark: Ind. Eng. Chem. Proc. Des. Dev., 1967, vol. 6(2), pp. 218–20.

K. Idogawa, K. Ikeda, T. Fukuda, and S. Morooka: Int. Chem. Eng., 1986, vol. 26, pp. 468–74.

K. Idogawa, K. Ikeda, T. Fukuda, and S. Morooka: Int. Chem. Eng., 1987, vol. 27, pp. 93–99.

E. Sada, A. Yasunzshz, S. Katoh, and M. Nzshioka: Can. J. Chem. Eng., 1978, vol. 56, pp. 669–72.

Y. Kawase and J.J. Ulbrecht: Ind. Eng. Chem. Process. Des. Dev., 1981, vol. 20(4), pp. 636–40.

C. Muilwijk and H.E.A. Vanden Akker: Chem. Eng. Sci., 2019, vol. 202, pp. 318–35.

P. Luty and M. Pronczuk: Processes, 2020, vol. 8, p. 999.

P.F. Wace, M.S. Morrell, and J. Woodrow: Chem. Eng. Commun., 1987, vol. 62, pp. 93–106.

I. Kim, Y. Kamotani, and S. Ostrach: AIChE J., 1994, vol. 40(1), pp. 19–28.

Y. Sahai and T. Emi: Tundish Technology for Clean Steel Production, 1st ed. World Scientific Publishing, Singapore, 2008, pp. 20–21.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 1143–59.

R. Banderas, R. Morales, R. Sanchez-Perez, L. Demedices, and G. Solorio-Diaz: Int. J. Multiphase Flow, 2005, vol. 31, p. 643.

J. Klostermann, H. Chaves, and R. Schwarze: Steel Res. Int., 2007, vol. 78(8), pp. 595–601.

S.M. Cho, B.G. Thomas, and S.H. Kim: ISIJ Int., 2018, vol. 58(8), pp. 1443–52.

M. Burty, M. Larrecq, C. Pusse, and Y. Zbaczyniak: 13th PTD Conf., Nashville, TN, 1995, vol. 13, pp. 287–92.

R. Sanchez-Perez, R. Morales, L. Demedices, J. Palafox-Ramos, and M. Díaz-Cruz: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 85–99.

R. Sanchez-Perez, R. Morales, M. Diaz-Cruze, O. Olivares-Xomet, and J. Palafox Ramos: ISIJ Int., 2003, vol. 43, pp. 637–46. https://doi.org/10.2355/isijinternational.43.637.

K. Jin, S. Vanka, and B. Thomas: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 1360–77.

T. Zhang, Z. Luo, H. Zhou, B. Ni, and Z. Zou: ISIJ Int., 2016, vol. 56(1), pp. 116–25.

K. Timmel, N. Shevchenko, M. Roder, M. Anderhuber, P. Gardin, S. Eckert, and G. Gerbet: Metall. Mater. Trans B, 2015, vol. 46B, pp. 700–10.

K. Timmel, S. Eckert, G. Gerbeth, F. Stefani, and T. Wondrak: ISIJ Int., 2010, vol. 50, pp. 1134–41.

A. Srivastava, R. Wang, S.K. Dinda, and K. Chattopadhyay: MLWA, 2021, vol. 6, p. 100180.

P. Kowalczuk and J. Drzymala: Particul. Sci. Technol., 2016, vol. 34, pp. 645–47. https://doi.org/10.1080/02726351.2015.1099582.

A. Srivastava and K. Chattopadhyay: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1018–35. https://doi.org/10.1007/s11663-021-02396-z.

V. Singh, S. Dash, J. Sunitha, and S. Ajmani: ISIJ Int., 2006, vol. 46, pp. 210–18. https://doi.org/10.2355/isijinternational.46.210.

W. Chen, Y. Ren, L. Zhang, and P. Scheller: JOM, 2019, vol. 71, pp. 1158–68.

A. Srivastava, S. K. Dinda, K. Chattopadhyay, and J. Sengupta, AISTech 2021, Proc. of the Iron & Steel Tech. Conf. Nashville, https://doi.org/10.33313/382/172

S. K. Dinda, A. Srivastava, K. Chattopadhyay, and J. Sengupta, AISTech 2021, Proc. of the Iron & Steel Tech. Conf. Nashville, https://doi.org/10.33313/382/171

A. Asgarian, Z. Yang, Z. Tang, M. Bussmann, and K. Chattopadhyay: Exp. Fluids, 2020, vol. 61, p. 14. https://doi.org/10.1007/s00348-019-2847-6.

A. Srivastava, R. Wang, D. Li, and K. Chattopadhyay, Proc. Of AISTech 2020, pp. 803–13, https://doi.org/10.33313/380/085

P.M. Wilkinson, PhD Thesis, University of Groningen, Groningen, The Netherlands, 1991

Q. Wu, X. Wang, T. Wang, M. Han, Z. Sha, and J. Wang: Can. J. Chem. Eng., 2013, vol. 91, pp. 1957–63.

G. Besagni, F. Inzoli, G. Deguido, and L.A. Pellegrini: Chem. Eng. Sci., 2016, vol. 158, pp. 509–38. https://doi.org/10.1016/j.ces.2016.11.003.

D. Laupsien, C.L. Men, A. Cockx, and A. Linè: Chem. Eng. Res. Des., 2021, https://doi.org/10.1016/j.cherd.2021.09.025.

P. Zahedi, R. Saleh, R.M. Atanasio, and K. Yousefi: Korean J. Chem. Eng., 2014, vol. 31(8), pp. 1349–61.

F. Liu, H. Zhou, L. Zhang, C. Ren, J. Zhang, Y. Ren, and W. Chen: Steel Res. Int., 2021, vol. 92, p. 2100067. https://doi.org/10.1002/srin.202100067.

Y. Liao and D. Lucas: Chem. Eng. Sci., 2009, vol. 64, pp. 3389–406.

Y. Liao and D. Lucas: Chem. Eng. Sci., 2010, vol. 65(10), pp. 2851–64.

Acknowledgments

The authors thank the Natural Sciences and Engineering Research Council of Canada (NSERC), ArcelorMittal, and the University of Toronto Dean’s Catalyst Professorship for funding this research.

Conflict of interest

The authors declare no conflict of interest in publishing this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (AVI 27600 KB)

Appendix

Appendix

Effect of Flow Rates on Bubble Coalescence

To understand the effect of flow rates on the bubble coalescence, a parameter called rate of bubble coalescence (fc) is used in this study.

Figure A1 shows the effect of liquid flow rate on the rate of coalescence at different gas flow rates. Liquid flow rate is dominating over gas flow rate and becomes a responsible factor for bubble coalescence as on increasing QL, fc increases significantly but on increasing Qg, it does not increase significantly.

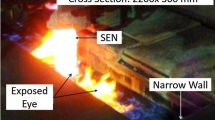

An increased liquid flow rate provides energy to the bubbles for coalescence to take place. Bigger bubbles produced after coalescence are responsible for the occurrence of slag–gas interaction-related defects such as open eye formation and slag layer shearing.

Rights and permissions

About this article

Cite this article

Srivastava, A., Dinda, S.K., Asgarian, A. et al. Bubble Size Measurement in a Continuous Casting Mold Using Physical Modeling and Shadowgraphy. Metall Mater Trans B 53, 2209–2226 (2022). https://doi.org/10.1007/s11663-022-02521-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02521-6