Abstract

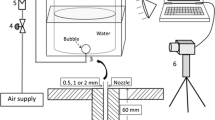

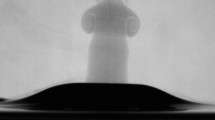

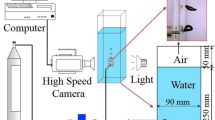

Bubble formation during gas injection into turbulent downward-flowing water is studied using high-speed videos and mathematical models. The bubble size is determined during the initial stages of injection and is very important to turbulent multiphase flow in molten-metal processes. The effects of liquid velocity, gas-injection flow rate, injection hole diameter, and gas composition on the initial bubble-formation behavior have been investigated. Specifically, the bubble-shape evolution, contact angles, size, size range, and formation mode are measured. The bubble size is found to increase with increasing gas-injection flow rate and decreasing liquid velocity and is relatively independent of the gas injection hole size and gas composition. Bubble formation occurs in one of four different modes, depending on the liquid velocity and gas flow rate. Uniform-sized spherical bubbles form and detach from the gas injection hole in mode I for a low liquid speed and small gas flow rate. Modes III and IV occur for high-velocity liquid flows, where the injected gas elongates down along the wall and breaks up into uneven-sized bubbles. An analytical two-stage model is developed to predict the average bubble size, based on realistic force balances, and shows good agreement with measurements. Preliminary results of numerical simulations of bubble formation using a volume-of-fluid (VOF) model qualitatively match experimental observations, but more work is needed to reach a quantitative match. The analytical model is then used to estimate the size of the argon bubbles expected in liquid steel in tundish nozzles for conditions typical of continuous casting with a slide gate. The average argon bubble sizes generated in liquid steel are predicted to be larger than air bubbles in water for the same flow conditions. However, the differences lessen with increasing liquid velocity.

Similar content being viewed by others

Abbreviations

- D :

-

instantaneous equivalent bubble diameter (mm)

- D N :

-

diameter of nozzle bore (mm)

- d :

-

gas injection hole diameter (mm)

- d :

-

subscript referring to instant of detachment, stage 2

- e :

-

elongation factor, L/D

- e :

-

subscript referring to end of expansion, stage 1

- F B :

-

buoyancy force for a bubble (Newton)

- F D :

-

drag force acting on a bubble from flowing liquid (Newton)

- F s :

-

surface-tension force on a bubble (Newton)

- F Sz :

-

vertical component of the surface-tension force on a bubble (Newton)

- f :

-

frequency of bubble formation (s−1)

- f θ :

-

contact-angle function, f θ=sin θ 0(cos θ−cos θ a )

- L :

-

elongation length at instant of detachment,= e dDd (mm)

- P b :

-

pressure in the bubble (Pascals)

- P g :

-

gas-injection pressure in Eq. [28] (Pascals)

- Q g :

-

gas-injection flow rate/hole (mL/s)

- r :

-

horizontal radius of an ellipsoidal bubble (mm)

- Rebub :

-

Reynolds number of a bubble, uD/v

- t :

-

time during bubble formation

- U :

-

average liquid velocity in the nozzle (m/s)

- u :

-

liquid-velocity profile across the nozzle bore, u(y) (m/s)

- ū :

-

average liquid velocity across the bubble (m/s)

- V b :

-

bubble volume (equal to πD 3/6) (mL)

- y, z :

-

horizontal and vertical coordinate directions (m)

- μ g, μl :

-

molecular viscosity of the gas and liquid respectively (kg/ms)

- θ 0 :

-

static contact angle (deg)

- θ a, θr :

-

advancing and receding contact angles of a forming bubble, respectively (deg)

- ρ g, ρl :

-

density of the gas and liquid, respectively (kg/m3)

- σ :

-

liquid surface tension (Newton/m)

- ν :

-

kinematic viscosity of the liquid,=μ l/ρl (m2/s)

References

N. Bessho, R. Yoda, T. Yamasaki, T. Fuji, T. Nozaki, and S. Takatori: Trans. ISS (Iron and Steelmaker), 1991, vol. 18 (4), pp. 39–44.

B.G. Thomas and X. Huang: 76th Steelmaking Conf. Dallas, TX, ISS, Warrendale, PA, 1993, vol. 76, pp. 273–89.

B.G. Thomas, X. Huang, and R.C. Sussman: Metall. Trans. B, 1994, vol. 25B, pp. 527–47.

B.G. Thomas, A. Dennisov, and H. Bai: 80th ISS Steelmaking Conf., Chicago, IL, 1997, ISS, Warrendale, PA, pp. 375–84.

J. Knoepke andM. Hubbard: 77th Steelmaking Conf., Washington, DC, 1994, ISS, Warrendale, PA, pp. 381–88.

L. Wang, H.-G. Lee, and P. Hayes: Iron Steel Inst. Jpn. Int., 1996, vol. 36 (1), pp. 7–16.

K. Tabata, T. Kakehi, and M. Terao: Shinagawa Technical Report No. 31, Shinagawa Refractries Co., Ltd., Japan, 1988.

M. Sano and K. Mori: Trans. JIM, 1976, vol. 17, pp. 344–52.

A. Thomas, S. Tu, and D. Janke: Steel Res., 1997, vol. 68 (5), pp. 198–200.

M. Sano, Y. Fujita, and K. Mori: Metall. Trans. B, 1976, vol. 7B, pp. 300–01.

M. Iguchi, H. Kawabata, K. Nakajima, and Z. Morita: Metall. Trans. B, 1995, vol. 26B, pp. 67–74.

G.A. Irons and R.I.L. Guthrie: Metall. Trans. B, 1978, vol. 9B pp. 101–10.

K.G. Davis, G.A. Irons, and R.I.L. Guthrie: Metall. Trans. B, 1978, vol. 9B, pp. 721–22.

M. Iguchi, T. Chihara, N. Takanashi, Y. Ogawa, N. Tokumitsu, and Z. Morita: Iron Steel Inst. Jpn. Int., 1995, vol. 35 (11), pp. 1354–61.

R.I.L. Guthrie: Engineering in Process Metallurgy, Clarendon Press, Oxford, United Kingdom, 1992, p. 457.

R. Kumar and N.R. Kuloor: in Advances in Chemical Engineering, Academic Press, New York, NY, 1970, vol. 8, pp. 255–368.

R. Clift, J.R. Grace, and M.E. Weber: Bubbles, Drops, and Particles, Academic Press, Inc., New York, NY, 1978.

H. Tsuge: Encyclopedia of Fluid Mechanics, Gulf Publishing Co., Houston, TX, 1986, vol. 3, pp. 191–232.

N. Rabiger and A. Vogelpohl: in Encyclopedia of Fluid Mechanics, Gulf Publishing Co., Houston, TX, 1986, vol. 3, pp. 58–88.

Z. Wang, K. Mukai, and D. Izu: Iron Steel Inst. Jpn. Int., 1999, vol. 39 (2), pp. 154–63.

J.F. Davidson and B.O.G. Schuler: Trans. Inst. Chem. Eng., 1960, vol. 38, pp. 335–42.

R. Kumar and N.R. Kuloor: Chem. Technol., 1967, vol. 19, p. 733.

W.V. Pinczewski: Chem. Eng. Sci., 1981, vol. 36, pp. 405–11.

K. Terasaka and H. Tsuge: J. Chem. Eng. Jpn., 1990, vol. 23 (2), pp. 160–65.

K. Terasaka and H. Tsuge: Chem. Eng. Sci., 1993, vol. 48 (19), pp. 3417–22.

H. Tsuge, Y. Nakajima, and K. Terasaka: Chem. Eng. Sci., 1992, vol. 47 (13–14), pp. 3273–80.

T. Hong, C. Zhu, and L.-S. Fan: 1996 ASME Fluids Division Conf., 1996, vol. FED 236, pp. 581–88.

C.W. Hirt and B.D. Nichols: J. Computational Phys., 1981, vol. 39, pp. 201–25.

S.C. Chuang and V.W. Goldschmidt: J. Basic Eng., 1970, vol. 92, pp. 705–11.

Y. Kawase and J.J. Ulbrecht: Ind. Eng. Chem. Process Des. Dev., 1981, vol. 20 (4), pp. 636–40.

I.B.V. Morgenstern and A. Mersmann: Germany Chem. Eng., 1982, vol. 5, pp. 374–79.

M. Burty, M. Larrecq, C. Pusse, and Y. Zbaczyniak: 13th PTD Conf., Nashville, TN, 1995, vol. 13, pp. 287–92.

R.H.S. Winterton: Chem. Eng. Sci., 1972, vol. 27, pp. 1223–30.

R.H.F. Pao: Fluid Dynamics, Merrill, New York, NY, 1967.

H. Bai: Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, 2000.

S.L. Soo: Multiphase Fluid Dynamics, Science Press, Gower, Beijing, 1990.

B.E. Launder and D.B. Spalding: Comp. Meth. Appl. Mech. Eng., 1974, vol. 13, pp. 269–89.

FLOW-3D User’s Manual, Flow Science Inc., Los Alamos, NM, 1997.

L. Jimbo, A. Sharan, and A.W. Cramb: 76th SteelMaking Conf., Dallas, TX, 1993, ISS, Warrendale, PA, pp. 485–94.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 253–67.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bai, H., Thomas, B.G. Bubble formation during horizontal gas injection into downward-flowing liquid. Metall Mater Trans B 32, 1143–1159 (2001). https://doi.org/10.1007/s11663-001-0102-y

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-001-0102-y