Abstract

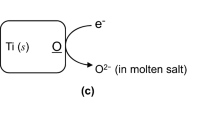

Metallic Ti has a strong affinity for O at high temperatures, and methods for removing O directly from Ti are limited. Recently, the authors developed a new sintering process that removes O from Ti using Y metal as a deoxidizing agent in molten salt. However, Y contaminated the sintered Ti body. To address this problem, the authors developed a new Ti deoxidation process using a metal filter. In this process, a Ti green made of Ti powder and Y metal are introduced with molten salt into the respective sides of a room divided by a Ti filter. O removed from the Ti green passes through the Ti filter and reacts with the Y metal. Meanwhile, the small solubility and diffusion coefficient of Y in β-Ti are expected to kinetically prevent Y contamination of the sintered Ti body. It was experimentally demonstrated that a sintered Ti product with a low-O-concentration (< 250 mass ppm O) can be produced while suppressing Y contamination (< 120 mass ppm Y) in the new process. The establishment of this process enables low-cost production of highly functional Ti products and the recycling of Ti scraps in the future.

Similar content being viewed by others

References

J.L. Murray and H.A. Wriedt: J. Phase Equilib., 1987, vol. 8, pp. 148–65.

T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak: Binary Alloy Phase Diagrams, 2nd ed. Materials Park, ASM International, 1990, p. 2926.

P. Waldner and G. Eriksson: Calphad., 1999, vol. 23, pp. 189–218.

J.L. Murray: Bull. Alloy Phase Diagr., 1981, vol. 2, pp. 320–34.

H. Bo, J. Wang, L. Duarte, C. Leinebach, L. Liu, H. Liu, and Z. Jin: Trans. Nonferrous Met. Soc. China., 2021, vol. 22, pp. 2204–11.

A. Iizuka, T. Ouchi, and T.H. Okabe: Mater. Trans., 2020, vol. 61, pp. 758–65.

T.H. Okabe, K. Hirota, E. Kasai, F. Saito, Y. Waseda, and K.T. Jacob: J. Alloys Compd., 1998, vol. 279, pp. 184–91.

T.H. Okabe, C. Zheng, and Y. Taninouchi: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 1056–66.

T.H. Okabe, C. Zheng, and Y. Taninouchi: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 3107–11.

C. Zheng, T. Ouchi, A. Iizuka, Y. Taninouchi, and T.H. Okabe: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 622–31.

C. Zheng, T. Ouchi, L. Kong, Y. Taninouchi, and T.H. Okabe: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 1652–61.

L. Kong, T. Ouchi, and T.H. Okabe: Mater. Trans., 2019, vol. 60, pp. 2059–68.

L. Kong, T. Ouchi, and T.H. Okabe: J. Electrochem. Soc., 2019, vol. 166, pp. 429–37.

A. Iizuka, T. Ouchi, and T.H. Okabe: Metall. Mater. Trans. B., 2020, vol. 51B(2), pp. 433–42.

T. Tanaka, T. Ouchi, and T.H. Okabe: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 1485–94.

T. Tanaka, T. Ouchi, and T.H. Okabe: J. Sustain. Metall., 2020, vol. 6, pp. 667–79.

L. Kong, T. Ouchi, and T.H. Okabe: J. Alloys Compd., 2021, vol. 863, p. 156047.

E.M. Savitskii and G.S. Burkhanov: Russ. J. Inorg. Chem., 1957, vol. 2, pp. 2609–16. (in Russian).

C.E. Lundin and D.T. Klodt: Trans. Metall. Soc. AIME., 1962, vol. 224, pp. 367–72.

N. T’en and I.S. Morozov: Russ. J. Inorg. Chem., 1969, vol. 14, pp. 1179–83.

D.V. Drobot, B.G. Korshunov, and L.V. Durinina: Inorg. Mater., 1968, vol. 1978–1985

J.D. Corbett, J.D. Smith, and E. Garcia: J. Less-Common Met., 1986, vol. 115, pp. 343–55.

Y.F. Yang, S.F. Li, M. Qian, Q.S. Zhu, C.Q. Hu, and Y. Shi: J. Alloys Compd., 2018, vol. 764, pp. 467–75.

B. Poorganji, A. Kazahari, T. Narushima, C. Ouchi, and T. Furuhara: J. Phys., 2010, vol. 240, pp. 1–4.

American Society for Testing and Materials: ASTM standards in building codes : specifications, test methods, practices, classifications, terminology, 38th ed., ASTM International, Philadelphia, Pennsylvania, 2001, p. 2017.

T.H. Okabe, R.O. Suzuki, T. Oishi, and K. Ono: Mater. Trans. JIM., 1991, vol. 32, pp. 485–8.

Barin: Thermochemical Data of Pure Substances, 3rd ed. VCH Verlagsgesellschaft mbH, Weinheim, 1995.

Y.B. Patrikeev, G.I. Novikov, and V.V. Badovskii: Russ. J. Phys. Chem., 1973, vol. 47, p. 284.

O. Knacke, O. Kubaschewski, and K. Hesselmann: Thermochemical Properties of Inorganic Substances, 2nd ed. Springer, Berlin, 1991.

C.J. Rosa: Metall. Trans., 1970, vol. 1, pp. 2517–22.

M.H. Song, S.M. Han, G.S. Choi, D.J. Min, and J.H. Park: Metall. Mater. Trans. A., 2009, vol. 49A, pp. 495–8.

A.D. LeClaire: Landolt-Börnstein - Group III Condensed Matter, Berlin, Germany, 1990.

Z.Z. Fang, Y. Xia, P. Sun, Y. Zhang, WO Patent No. 2016/090052 Al, 2016.

Y. Zhang, Z.Z. Fang, P. Sun, T.Y. Zhang, Y. Xia, C.S. Zhou, and Z. Huang: J. Am. Chem. Soc., 2016, vol. 138(2016), pp. 6916–9.

J.M. Oh, K.M. Roh, and J.W. Lim: Int. J. Hydrog., 2016, vol. 41, pp. 23033–41.

C. Hong, J.M. Oh, J. Park, J.M. Yoon, and J.W. Lim: Adv. Powder Technol., 2018, vol. 29, pp. 1640–3.

J.M. Oh, C. Hong, and J.W. Lim: Adv. Powder Technol., 2019, vol. 30, pp. 1–5.

M. Watanabe, F. Sato, R. Abe, K. Ueda, D. Matsuwaka, F. Kud, and T. Narushima: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 1553–8.

Y. Su, L. Wang, L. Luo, X. Jaing, J. Guo, and H. Fu: Int. J. Hydrog., 2009, vol. 34, pp. 8958–63.

Y. Xia, J. Zhao, Q. Tian, and X. Guo: JOM., 2019, vol. 71, pp. 3209–20.

Y. Xia, Z.Z. Fang, D. Fan, P. Sun, Y. Zhang, and J. Zhu: Int. J. Hydrog., 2018, vol. 43, pp. 11939–51.

S. Kim, J. Oh, and J. Lim: Met. Mater. Int., 2016, vol. 22, pp. 658–62.

K. Roh, C. Suh, J. Oh, W. Kim, H. Kwon, and J. Lim: Powder Technol., 2014, vol. 253, pp. 266–9.

Y. Zhang, W. Lu, P. Sun, Z.Z. Fang, S. Qiao, Y. Zhang, and S. Zheng: Int. J. Refract. Met. Hard Mater., 2020, vol. 91, p. 105270.

T. Narushima, K. Ueda, and R. Abe: J. Jpn. Inst. Light Met., 2020, vol. 70, pp. 316–7. (in Japanese).

D. Matsuwaka, F. Kudo, H. Ishida, and T. Deura: MATEC Web Conf., 2020, vol. 321, p. 10002.

Acknowledgments

The authors are grateful to Dr. Gen Kamimura, Mr. Kenta Akaishi, and Mr. Hiromu Hiramatsu at The University of Tokyo for their helpful suggestions and help with the experiments. This work was financially supported by the Japan Society for the Promotion of Science (JSPS) through a Grant-in-Aid for Scientific Research (S) (KAKENHI Grant Nos. 26220910, and 19H05623). This work is also based on results obtained from a project commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 29, 2021; accepted November 20, 2021.

Rights and permissions

About this article

Cite this article

Iizuka, A., Ouchi, T. & Okabe, T.H. New Deoxidation Method of Titanium Using Metal Filter in Molten Salt. Metall Mater Trans B 53, 1371–1382 (2022). https://doi.org/10.1007/s11663-021-02400-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02400-6