Abstract

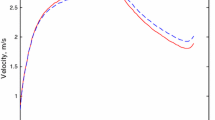

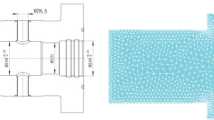

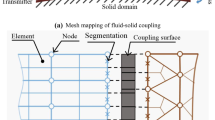

A water model experiment and a transient 3D numerical model were designed and implemented to quantitatively evaluate the flow-induced erosion behavior of the refractory lining in a continuous casting tundish. A relationship between the erosion rate and flow characteristic parameters was proposed and experimentally verified. Boric acid tablets were used in the water model experiment to determine the flow-induced erosion rate, and the numerical model defined the two-phase flow pattern. The results indicate that the impacting and rubbing effects caused by the fluid flow can be quantitatively characterized by the turbulent kinetic energy and wall shear stress. The proposed empirical dependence describes the erosion rate of the boric acid tablet with acceptable accuracy. The most serious erosion occurs inside the turbulence inhibitor, and the erosion rate sharply drops and steadily reduces with the water flow outside the turbulence inhibitor. The influence of casting speed on the refractory erosion rate is also quantitatively analyzed using the developed model with the introduction of the proposed correction.

Similar content being viewed by others

Abbreviations

- \(C_{{\text{f}}}\) :

-

Skin friction coefficient

- \(c_{{\text{t}}}\) :

-

Dimensionless concentration of tracer

- \(D_{\varphi }\) :

-

Diffusion coefficient of tracer in water (m2/s)

- \(\vec{F}_{{{\text{ST}}}}\) :

-

Interfacial tension (N/m3)

- \(p\) :

-

Pressure (Pa)

- \(Re\) :

-

Reynolds number

- \(R_{{\text{t}}}\) :

-

Turbulent kinetic energy erosion rate (kg/s)

- \(R_{{\text{w}}}\) :

-

Wall shear stress erosion rate (kg/s)

- \(R_{{{\text{overall}}}}\) :

-

Total erosion rate (kg/s)

- \(Sc_{{\text{t}}}\) :

-

Turbulence Schmidt number

- \(t\) :

-

Time (s)

- \(\Delta t\) :

-

Time step (s)

- \(V_{{{\text{cell}}}}\) :

-

Volume of a computational cell (m3)

- \(\vec{v}\) :

-

Velocity (m/s

- \(\alpha\) :

-

Volume fraction of air

- \(\bar{\mu }\) :

-

Dynamic viscosity (Pa s)

- \(\mu _{{\text{t}}}\) :

-

Turbulent viscosity (m2/s)

- \(\bar{\rho }\) :

-

Density of mixture phase (kg/m3)

- \(\rho _{{{\text{ba}}}}\) :

-

Density of boric acid tablet (kg/m3)

- \(\rho _{{\text{w}}}\) :

-

Density of water (kg/m3)

- \(\bar{\phi }\) :

-

Physical property of mixture phase

- \(\phi _{{\text{a}}}\) :

-

Physical property of air

- \(\phi _{{\text{w}}}\) :

-

Physical property of water

References

L. Zhang and B.G. Thomas: ISIJ Int., 2003, vol. 43, pp. 271–91. .

K. Badr, M. Tomas, M. Kirschen, and G. Mcllveney: RHI Bull., 2011, vol. 1, pp. 43–50. .

M.C. Mantovani, L.R. Moraes Jr., R. Leandro da Silva, E.F. Cabral, E.A. Possente, C.A. Barbosa, and B.P. Ramos: Ironmak. Steelmak., 2013, vol. 40, pp. 319–25. .

K.N. Vdovin, V.V. Tochilkin, and V.V. Tochilkin: Refract. Ind. Ceram., 2016, vol. 57, pp. 221–3. .

V. Frishfelds, J.G.I. Hellström, T.S. Lundström, and H. Mattsson: Transp. Porous Media., 2011, vol. 89, pp. 441–57. .

R. Barker, X. Hu, A. Neville, and S. Cushnaghan: Corrosion., 2013, vol. 69, pp. 193–203. .

W. Dai, S. Cremaschi, H.J. Subramani, and H.J. Gao: Wear., 2018, vol. 408–409, pp. 108–19. .

E.V. Senatore, W. Taleb, J. Owen, Y. Hua, J.A.C. Ponciano Gomes, R. Barker, and A. Neville: Wear., 2018, vol. 404–405, pp. 143–52. .

B.C. van Prooijen and J.C. Winterwerp: J. Geophys. Res., 2010, vol. 115, p. C01005. .

J.C. Winterwerp, W.G.M. van Kesteren, B. van Prooijen, and W. Jacobs: J. Geophys. Res., 2012, vol. 117, p. C10020. .

Q. Wang, Y. Liu, A. Huang, W. Yan, H.Z. Gu, and G.Q. Li: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 276–92. .

A.M. Guzmán, D.I. Martínez, and R. González: Eng. Fail. Anal., 2014, vol. 46, pp. 188–95. .

K. Takatani, T. Inada, and K. Takata: ISIJ Int., 2001, vol. 41, pp. 1139–45. .

M.Y. Zhu, W.T. Lou, and W.L. Wang: Acta Metall. Sin., 2018, vol. 54, pp. 131–50. (in Chinese).

P.H.R. Vaz de Melo, J.J.M. Peixoto, G.S. Galante, B.H.M. Loiola, C.A. da Silva, I.A. da Silva, and V. Seshadri: J. Mater. Res. Technol., 2019, vol. 8, pp. 3764–71. .

S.Y. Hu, R. Zhu, R.Z. Liu, K. Dong, and Z.H. Li: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 3317–29. .

C.W. Hirt and B.D. Nichols: J. Comput. Phys., 1981, vol. 39, pp. 201–25. .

H.T. Ling, R. Xu, H.J. Wang, L.Z. Chang, and S.T. Qiu: ISIJ Int., 2020, vol. 60, pp. 499–508. .

S. Neumann, A. Asad, T. Kasper, and R. Schwarze: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 2334–42. .

C. Chen, L.T.I. Jonsson, A. Tilliander, G.G. Cheng, and P.G. Jönsson: Metall. Mater. Trans. B., 2015, vol. 46B, pp. 169–90. .

P.Y. Ni, L.T.I. Jonsson, M. Ersson, and P.G. Jönsson: Steel Res. Int., 2017, vol. 83, p. 1600155. .

Z.Q. Liu, A. Vakhrushev, M. Wu, A. Kharicha, A. Ludwig, and B.K. Li: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 543–54. .

Z.Q. Liu, Y.D. Wu, and B.K. Li: Powder Technol., 2020, vol. 374, pp. 470–81. .

H.C. Zhu, H.B. Li, Z.Y. He, H. Feng, and Z.H. Jiang: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 2976–92. .

Acknowledgments

The authors appreciated the financial support from National Natural Science Foundation of China (Grant No. U1860205). Thanks are also given to the Baoshan Iron and Steel Co., Ltd. for supporting plant data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 21, 2020; accepted June 7, 2021.

Rights and permissions

About this article

Cite this article

Wang, Q., Tan, C., Huang, A. et al. Quantitative Characterization of Flow-Induced Erosion of Tundish Refractory Lining via Water Model Experiment and Numerical Simulation. Metall Mater Trans B 52, 3265–3275 (2021). https://doi.org/10.1007/s11663-021-02254-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02254-y