Abstract

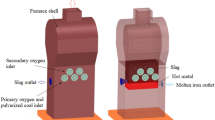

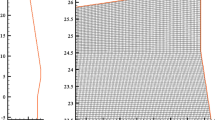

For an oxygen bottom blowing converter, a high-temperature fire spot zone forms above the tuyere owing to oxygen reaction. The bottom blowing tuyere and surrounding brick are simultaneously heated by high-temperature fire spot and flowing molten steel. High-speed fluids flowing in the inner tube and the annular gap of the tuyere can remove part of the heat transferred from the fire spot zone and molten steel, playing a vital role in cooling the tuyere. To determine the temperature distributions of the tuyere and surrounding brick under the condition of oxygen bottom blowing, a fluid–solid coupling heat transfer numerical model that considers both the radiation of the fire spot and convection of the molten steel was established in this study. The simulation results agree well with previous experimental results; thus, the numerical model was validated. Utilizing the validated model, the influences of the tuyere inner tube material and fire spot zone temperature on the tuyere temperature distribution were studied in detail. Along with an increase in the material thermal conductivity, the maximum temperature of the inner tube at the hot face decreased, verifying the superiority of copper as the inner tube. More importantly, it was found that reducing the fire spot zone temperature by mixing CO2 in the bottom blowing oxygen fundamentally alleviated the burning loss of the tuyere and the surrounding brick.

Similar content being viewed by others

References

J.K. Brimacombe: Proc. of the Savard/Lee International Symposium on Bath Smelting, TMS, 1992.

G. Savard and R.G.H Lee: US Patent 4336064, 1982.

E. Fritz: Proc. of International Symposium on Modern Developments in Steelmaking, NML, Jamshedpur, 1981.

K. Nakanishi, and K. Sanbongi: Tetsu-to- Hagane, 1979, vol. 65, pp. 138-147.

K. Nakanishi, T. Nozaki, and R. Uchimura: Kawasaki Steel Technical Report, 1980, pp. 1–13.

J. Pearce and E.G. Schempp: Proc. of International Symposium on Modern Developments in Steelmaking, NML, Jamshedpur, 1981.

K. Deng: Iron & Steel, 1979, vol. 26, pp. 61-70

Y. Li: Iron & Steel, 1980, vol. 27, pp. 1-9

H. Sun, Y. Liu, and M. Lu: Ironmaking & Steelmaking, 2016, vol. 43, pp. 697-704.

G. Wimmer, K. Pastucha, and E. Wimmer: The 6th International Congress on Science and Technology of Steelmaking, 2015.

Y. Zhong, L. Guan, and M. Lin: Iron & Steel, 1979, vol. 26, pp.34-44

M. Abe, Y. Kishimoto, and S. Takeuchi: Tetsu- to- Hagane, 2009, vol. 82, pp. 743-748.

S. Sun, D. Liao, N. Pyke: Iron Steel Tech., 2008, vol. 5, pp. 36-42.

T. Kosukegawa, T. Imai, and F. Sudo: Proc. of International Symposium on Modern Developments in Steelmaking, NML, Jamshedpur, 1981.

D. Liao, S. Sun, and S. Waterfall: The 6th International Congress on Science and Technology of Steelmaking, 2015.

G. Denier, J.C. Frosjjean, and H. Zanetta: Ironmaking and steelmaking, 1980, vol. 7, pp. 123-126.

N. Harada: Tetsu- to- Hagane, 1983, vol. 69, pp. 1010-1011.

R. Ruther, and P. Opel: Neue Hutte, 1978, vol. 23, pp. 254-257.

I.V. Belov: Izv. Akad. Nauk. SSSR, 1997, vol.4, pp. 16-21.

K. Scheidig, R. Guther, and G. Fromer: Neue Hutte, 1980, vol. 25, pp. 207-210.

N.B. Ballal, and A. Ghosh: Metall. Trans B, 1981, vol. 12, pp. 525-534.

Q. Song, S. Sun, and Y. Li: J. of Iron and Steel Res., 1992, vol. 12, pp. 33-40

Y. Wei, and L. Dong: J. Iron and Steel Res., 1991, vol. 11, pp. 9-16

Y. Li, Q. Song, S. Sun, and Y. Lu: Steelmaking, 1990, vol. 6, pp. 41-45

L. Wen, R. Guo, D. Chen, and J. Li: The Chinese J. of Process Eng., 2009, vol. 34, pp. 379-383

G. Zhu, Z. Yang, B. Wang, and H. Zhao: J. Univ. Sci. Technol. Beijing, 2007, vol. 53, pp. 325-328.

T.H. Shih, W.W. Liou, A. Shabbir, Z. Yang, and J. Zhu: Computers Fluids, 1995, vol. 24, pp. 227-238

S.E. Kim, D. Choudhury, and B. Patel: Proc. of the ICASE/LARC/AFOSR Symposium on Modeling Complex Turbulent Flows, 1997.

W.C. Reynolds: Lecture Notes for Von Karman Institute Award Report, 1987.

R. Siegel and J.R. Howell: Thermal Radiation Heat Transfer, CRC Press, Boca Raton, 2011. ISBN 0-89116-506-1

N. Katoh and T. Kuriyama: JSAE Conf. Proc., 1994.

X. Ma, H. Meng, and X. Gao: Iron Steel Vanadium Titanium, 2004, vol. 25, pp. 64-68.

A. Yan: J. Wuhan Univ. Sci. Technol., 2010, vol. 33, pp. 255-258.

Z. Guo, X. Ren, and J Zhou: J. of Iron and Steel Res., 2003, vol. 15, pp. 1-4.

Bakker, J., and Sinnema, S.: Refractories in Steelmaking, 2001, vol. 27, pp. 165-167.

S. Uchida, and O. Nomura: Taikabutsu Overseas, 2002, vol. 22, pp. 86–94.

O. Volkova, and D.Janke: ISIJ Int., 2007, vol. 43, pp.1185-1190.

L. Guan, and C. Wang: Industrial Heating, 2004, vol. 33, pp. 14-16

M. Lv, R. Zhu, and X. Wei: Steel Research Int., 2012, vol. 83, pp. 11-15.

Acknowledgments

The authors would like to extend their sincere grateful for the support by National Natural Science Foundation of China (Nos. 51574021, 51474024, and 51604022).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 30, 2018.

Rights and permissions

About this article

Cite this article

Hu, S., Zhu, R., Liu, R. et al. Fluid–Solid Coupling Simulation on the Temperature Distribution of Tuyere Used for Oxygen Bottom Blowing Converter. Metall Mater Trans B 49, 3317–3329 (2018). https://doi.org/10.1007/s11663-018-1375-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1375-8