Abstract

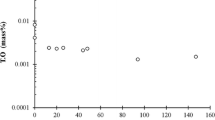

This work presents post-mortem microstructural analysis on the inner surfaces of single-use ladle shrouds of a ten-heat casting series of Ti-alloyed, Al-killed IF steel, in continuation of earlier work on the origin of alumina clogging formation in the casting system. It is found that ladle shrouds can be used as a representative sampler of materials exiting the ladle during the casting, which can be used to extract useful information about processes taking place in the shrouds and lower ladle during casting. All shrouds showed no ladle glaze emission but significant clog-like deposition of alumina. The alumina particles occur in two main forms (NMI embedded in the steel and alumina powder) and show the same two PDF populations (small Population I and coarse Population II) with the cross over at 5 µm, as the alumina particles found in the tundish clog of the same cast series. Detailed characterisation of inclusions in the shrouds revealed metal sub-inclusions containing Cr and Si, also similar to the tundish clogs. Thus, the hypothesis that the coarser population originates from the local oxidation of the steel in ladle bottom interface and ladle well region, including the well filler sand, is evidenced in this study. The fine Population I (often associated with dendritic and planar shapes) seen in the tundish clog, appears to be related to local carbothermic reaction in the ladle shrouds. Microstructures found on the surfaces on the shrouds are extensively shown and characterised.

taken from the white box, with a scale bar of 50 µm. The gap between the steel and alumina powder visible on both panels is an artefact resulting from separation between the deposits and the underlying refractory during cooling

Similar content being viewed by others

References

G.C. Duderstadt, R.K. Iyengar, J.M. Matesa, J. Met. 20, 89–94 (1968)

S. Basu, S.K. Choudhary, N.U. Girase, ISIJ Int. 44, 1653–1660 (2004)

M. Nadif, J. Lehmann, M. Burty, J.F. Domgin, Rev. Met. Paris 104, 493–500 (2007)

J.H. Lee, M.H. Kang, S.K. Kim, J.H. Kim, M.S. Kim, Y.B. Kang, ISIJ Int. 59, 749–758 (2019)

M. Burty, L. Peeters, E. Perrin, S. Münzer, P. Colucci, D. Salvadori, F. Schadow, J.M. Valcarcel, J. Claes, Rev. Met. Paris 102, 745–751 (2005)

J.H. Lee, Y.B. Kang, ISIJ Int. 60, 258–266 (2020)

J.H. Lee, Y.B. Kang, ISIJ Int. 60, 426–435 (2020)

E. Zinngrebe, J. Small, S.R. van der Laan, A. Westendorp, Metall. Mater. Trans. B (2020). https://doi.org/10.1007/s11663-020-01903-y

K. Karnasiewicz, E. Zinngrebe, Metall. Mater. Trans. B 50B, 1704–1717 (2019)

E. Zinngrebe, C. van Hoek, H. Visser, A. Westendorp, I.H. Jung, ISIJ Int. 52, 52–61 (2012)

M. Seo, J.W. Cho, K.C. Kim, S.H. Kim, ISIJ Int. 54, 475–481 (2014)

W. Yang, Y. Zhang, L.F. Zhang, H. Duan, L. Wang, J. Iron Steel Res. Int. 22, 1069–1077 (2015)

M. Van Ende, M. Guo, E. Zinngrebe, B. Blanpain, I.H. Jung, ISIJ Int. 53, 1974–1982 (2013)

J. Zhang, Q. Liu, S. Yang, Z. Chen, J. Li, Z. Jiang, ISIJ Int. 59, 1167–1177 (2019)

Z. Deng, B. Glaser, M.A. Bombeck, D. Sichen, Steel Res. Int. 87, 484–493 (2015)

M. Higgins: Am. Miner., 2000, vol. 85, pp. 1105–16. Program CSD Corrections obtainable at http://www.uqac.ca/mhiggins/csdcorrections.html.

M.A. Van Ende, M. Guo, E. Zinngrebe, R. Dekkers, J. Proost, B. Blanpain, P. Wollants, Ironmak. Steelmak. 36, 201 (2009)

K.G. Rackers and B. Thomas: Proc. 78th Steelmak. Conf., Nashville, 1995, pp. 723–34.

R. Dekkers, B. Blanpain, P. Wollants, F. Haers, B. Gommers, C. Vercruyssen, Steel Res. Int. 74, 351–355 (2003)

F. Tehovnik, J. Burja, B. Arh, M. Knap, Metalurgija 54, 371–374 (2015)

Z. Deng, B. Glaser, M.A. Bombeck, D. Sichen, Steel Res. Int. 87, 921–929 (2016)

K. Beskow, D. Sichen, Ironmak. Steelmak. 31, 393–400 (2004)

Y.G. Chi, Z.Y. Deng, M.Y. Zhu, Steel Res. Int. 88, 1600470 (2017)

J.H. Son, I.H. Jung, S.M. Jung, H. Gaye, H.G. Lee, ISIJ Int. 48, 1542–1551 (2008)

O. Adaba, P. Kaushik, R. O’Malley, S. Lekakh, L. Von Richards, E. Mantel, R. Hall, E. Ellis, Iron Steel Technol. 31, 38–49 (2017)

N. Tripathi: Licentiate Thesis, KTH Stockholm, Sweden, 2003.

Acknowledgments

The authors thank Tata Steel for the permission to publish this work. The authors acknowledge and thank SR van der Laan for helpful discussions and great support during the research. We also want to thank F. van der Does for material preparation. Two anonymous reviewers are thanked for their helpful comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 1, 2020; accepted April 13, 2021.

Rights and permissions

About this article

Cite this article

Karnasiewicz, B., Zinngrebe, E. & Tiekink, W. Post-mortem Ladle Shroud Analysis from the Casting of Al-Killed Steel: Microstructures and Origin of Alumina Clogging Deposits. Metall Mater Trans B 52, 2171–2185 (2021). https://doi.org/10.1007/s11663-021-02189-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02189-4