Abstract

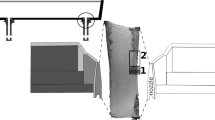

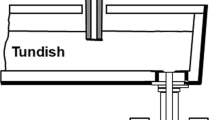

The continuous casting of Ti-alloyed Al-killed steels traditionally experiences clogging in the tundish, impeding stable operation. We studied the microstructures and mode of formation of such clogging deposits in tundish skulls recovered after long cast series. We sampled the steel skull along the whole tundish bottom from under the ladle shroud (impact zone) up to the tundish well and nozzle. The microstructures imply that the steel solidifies to the refractory (gunning mass) and remains partially solid through the entire cast. Thus, a “mushy zone” of steel loaded with solid delta ferrites is present along the margins of the steel during casting. In this mushy zone, the widely observed clusters of variably sintered alumina (NMI) accumulate, along with a substantial amount of gas bubbles acting as inclusion scavengers. The clustered alumina particles show a lognormal particle size distribution (PSD) in all locations, which becomes more pronounced if correcting for the observable sintering. Sintering of alumina size distributions linearizes a PSD, and further evolution, once the deposit is locked in place, occurs by Ostwald ripening, introducing skewness to the distributions. The observed PSDs contrast with the established log-linearity of PSDs of individual floating alumina NMI in the bulk steel, and suggest that the source of the alumina in the clogging deposits is not the passing bulk steel. However, ubiquitous sedimentary features show that the alumina particles are also not grown by reoxidation in situ. An upstream source separate from the bulk stream must be inferred, which is also required by the consistent sporadic presence of oxidic materials which cannot be derived from local sidewall reaction. In summary, the development of clogging deposits in this type of steel is an example of “slurry casting” of partially solidifying steel over thermal loss surfaces of refractories in the nozzle area.

Similar content being viewed by others

Change history

21 July 2020

This article was updated to correct errors in figure order and citations introduced during production.

References

Gao, Y. & Sorimachi, K.: ISIJ Int. (1993) 33:291-297

K.G. Rackers and B. Thomas: Proc. 78th Steelmaking Conf., Nashville, 1995, pp. 723–34.

Matsui, T., Ikemoto, T., Sawano, K., Sawada, I.: Taikabutsu Overseas, (1997) 18: 3-9

J. Smith and K. Peaslee: AISI/DOE Technology Roadmap Program Final Report, Pittsburgh, 2002, p. 229.

Andersson, M., Appelberg, J., Tilliander, A., Nakajima, K., Shibata, H., Kitamura, S., Jonsson, L., Jönsson, P.: ISIJ Intl. (2006) 46: 814-823

V. Garcia da Silva: PhD thesis, PPGEM (UFRGS), Porto Alegre, 2009, p. 98.

K. Janiszewski and Z. Kudlinski: Metal 2006 Conf., 2006, pp. 1–9.

L. Zhang and B. Thomas: XXIV. Natl. Steelmaking Symposium, Morelia, 2003, pp. 138–83.

Alekseenko, A., Baibekova, E., Kuznetsov, N., Baldaev, B., Ziborov, A., Ponomarenko, D., Ponomarenko, A.: Russian metallurgy (Metally) (2007), 7:94-97

Pack, A., Hoernes, S., Goebbels, M., Bross, R., Buhr, A.: Eur. J. Min. (2005), 17: 483-493

Khanna, R., Ikram Ul-Haq, M., Wang, Y., Seetharaman, S., Sahajwalla, V.: Met. Mat. Trans. Ser. B, (2011), 42B: 677-684

Lee JH, Kang MH, Kim SK, Kim J, Kim MS, Kang YB: ISIJ Int., 2019, 59, 749-758.

Burty, M., Peeters, L., Perrin, E., Münzer, S., Colucci, P., Salvadori, D., Schadow, F., Valcarcel, J., & Claes, J.: Rev. de Metallurgie (2005), 11:745-751

Zinngrebe, E., Van Hoek, C., Visser, H., Westendorp, A. & Jung, IH: ISIJ Intl. (2012), 52:52-61

Van Ende, MA, Guo, M., Zinngrebe, E., Dekkers, R., Proost, J., Blanpain, B. & Wollants, P.: Ironmaking Steelmaking (2009), 36:201-208

Randolph, A. & Larsen, M.: Theory of Particulate Processes, 2nd edn. Academic Press, San Diego, 1988.

Higgins, M.: Am. Miner. (2000), 85:1105-1116

Van Ende, M., Guo, M., Zinngrebe, E., Blanpain, B., Jung, IH.: ISIJ Intl. (2013), 53:1974-1982

Seo, M., Cho, JW, Kim, KC, & Kim, SH: ISIJ Intl. (2014), 54:475-481

Yang, W., Zhang, Y, Zhang, LF, Duan, H., Wang, L.: J. Iron Steel Res. Intl. (2015), 22:1069-1077

Adaba, O., Kaushik, P., Omalley, R., Lekakh, S., Von Richards, L., Mantel, E., Hall, R., Ellis, E.: Iron Steel Technol., 31, 38-49 (2017).

O. Adaba: Dissertation, University of Missouri – La Rolla, Doctoral Dissertations 2801, 2019. https://scholarsmine.mst.edu/doctoral_dissertations/2801

Zhang, L. & Pluschkell W.: Ironmaking & Steelmaking (2003), 30: 106-110

Eberl, D., Drits, V., & Srodon, J.: Am. J. Sci. (1998), 298:499-533

McCoy, B.: J. Colloid and Interface Sci. (2001), 240: 139-149

Kalisz, D., Zak, P.: Kovove Mater. (2015), 53:35-41

Ma, Z., Janke, D.: ISIJ Intl. (1998), 38: 46-52

Flemings, MC.: Metallurgical Transactions Ser. A (1991), 22A:957-981

Zhao, DG, Gao, M., Wang, SH, Wang, YF: Ironmaking Steelmaking (2016), 44:578-594

Acknowledgments

We thank Tata Steel for permission to publish. Many colleagues at Tata Steel collaborated in this work. Special thanks for their collaboration go to Frank van der Does, Corrie van Hoek, Patricia Romano Triguero, Erwin Bouwens, Henk Visser, Wouter Tiekink, Arnoud Kamperman, Bernadeta Karnasiewicz and Gert Abbel. The research also profited from discussions with colleagues outside of Tata Steel, especially In Ho Jung, Marie Aline van Ende and Joo Hyun Park. The reviewer’s efforts helped to significantly improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 31, 2018.

This article was updated to correct image citation and ordering errors introduced during production.

Rights and permissions

About this article

Cite this article

Zinngrebe, E., Small, J., van der Laan, S. et al. Microstructures and Formation of Tundish Clogging Deposits in Ti-Alloyed Al-Killed Steel. Metall Mater Trans B 51, 2321–2338 (2020). https://doi.org/10.1007/s11663-020-01903-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01903-y