Abstract

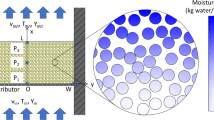

When liquid flows in an operating packed bed, some volume of the liquid remains in the bed at any instant of time. This is known as total liquid holdup. When the liquid flow is stopped, some portion remains static in the bed and the rest drains out. The first portion of the total liquid holdup is known as the static liquid holdup. The extent of the static liquid holdup affects mass transfer, heat transfer, permeability, as well as productivity of a packed bed reactor. Experimental and fundamental research has been performed to calculate the extent of static liquid holdup for last several decades. Many empirical correlations have been developed and mathematical models have been made in pursuit of quantifying this. However, significant difference in the experimental observations and modeling results can still be seen in the literature. In this work, a fundamental building block of a packed bed, i.e., a two-sphere contact, has been taken as the investigation domain. Experiments have been performed to understand how liquid films are formed, their shapes and variation of maximum static film volume before dripping, with respect to inclination for specific contact angles. Dripping involves formation and draining of droplets, and a volume remaining at the contact after dripping; these are measured for various inclinations of the sphere contact axis. Notionally, static liquid holdup is the volume of the liquid that can be held at the two-sphere contacts due to the interplay between static forces namely the surface tension and gravitational force. Hence, the mathematical model incorporating only static forces to capture the three-dimensional liquid shape at the two-sphere contacts, developed in a previous work of our group, is used in this work, and it is shown that the maximum volume of liquid before the liquid dripping can be very well captured for various inclinations. On the other hand, the remaining volume calculated from the mathematical model, with the assumption of quasistatic droplet detachment, results in much underprediction. When the two-sphere experimental values are extended to packed bed situations, it can be shown that the static liquid holdup calculated from the remaining volume after dripping matches are closer to the packed bed experimental values, whereas static liquid holdup calculated from maximum volume leads to overprediction.

Similar content being viewed by others

Notes

Turner and Hewitt’s correlation is modified in terms of inclination (φ). The present author calculate φ from the vertical axis (φ = 0, when vertical) whereas Turner and Hewitt have calculated from horizontal axis.

Abbreviations

- A :

-

Area (m2)

- Bo:

-

Bond number (Dimensionless)

- \( Bo^{\prime} \) :

-

Dimensionless Bond number (dimensionless)

- C p :

-

Capillary number (dimensionless)

- C pm :

-

Modified capillary number (dimensionless)

- \( d_{p}^{{}} \) :

-

Sphere diameter (m)

- Eo:

-

Eotvos number (dimensionless)

- \( E_{\text{total}} \) :

-

Total energy of an element (joules)

- \( g \) :

-

Gravitational acceleration (m/s2)

- \( h_{s} \) :

-

Static liquid holdup (dimensionless)

- \( H \) :

-

Mean curvature (1/m)

- K :

-

Coefficient (dimensionless)

- N :

-

Co-ordination number of the sphere in a packed bed (dimensionless)

- \( N_{c} \) :

-

Dimensionless contact angle (dimensionless)

- P :

-

Pressure (Pascal)

- q :

-

Index (dimensionless)

- \( R_{1} ,R_{2} \) :

-

Principal radii of curvature (m)

- \( V \) :

-

Volume of the liquid (m3 or microliter)

- \( V_{\dim } \) :

-

Volume of the film/volume of the sphere (dimensionless)

- \( V_{\dim }^{\text{avg}} \) :

-

Dimensionless volume averaged over all the inclinations (dimensionless)

- z :

-

Height of the element from the reference plane (m)

- \( \theta \) :

-

Equilibrium contact angle (dimensionless/degrees)

- \( \varphi \) :

-

Inclination (vertical to be 0) (dimensionless/degrees)

- \( \rho \) :

-

Density of the liquid (kg/m3)

- \( \varepsilon \) :

-

Void fraction (dimensionless)

- \( \sigma \) :

-

Surface tension (N/m)

- \( \delta \) :

-

Signifies the elemental quantity

- *:

-

Dimensionless

- o :

-

Reference

- max:

-

Quantity corresponding to maximum volume

- rem:

-

Quantity corresponding to remaining volume

- l :

-

Liquid

- s :

-

Solid

- g :

-

Gas

References

1 S. Ghosh, N.N. Viswanathan, and N.B. Ballal: Steel Res. Int., 2017, vol. 88, pp. 1–25.

2 H.L. Shulman, C.F. Ullrich, A.Z. Proulx, and J. Zimmerman: AIChE J., 1955, vol. 1, pp. 253–8.

3 H.L. Shulman, C.F. Ullrich, and N. Wells: AIChE J., 1955, vol. 1, pp. 247–53.

4 V.S. Patwardhan: AIChE J., 1963, vol. 9, pp. 331–7.

5 V.S. Patwardhan and V.R. Shrotri: Chem. Eng. Commun., 1981, vol. 10, pp. 349–55.

6 P.J. Mackey and N.A. Warner: Chem. Eng. Sci., 1973, vol. 28, pp. 2141–54.

7 P.J. Mackey and N.A. Warner: Metall. Trans. B, 1972, vol. 3, pp. 1807–16.

8 G.C. Gardner: Chem. Eng. Sci., 1956, vol. 5, pp. 101–13.

9 J.C. Charpentier and M. Favier: AIChE J., 1975, vol. 21, pp. 1213–8.

10 T. Fukutake and V. Rajakumar: Trans. ISIJ, 1982, vol. 22, pp. 355–65.

11 W. Xiong, X.-G. Bi, G.-Q. Wang, and F. Yang: Metall. Mater. Trans. B, 2012, vol. 43, pp. 562–70.

12 H. Kawabata, K. Shinmyou, T. Harada, and T. Usui: Tetsu-to-Hagane, 2017, vol. 92, pp. 893–900.

13 C.N. Schubert, J.R. Lindner, and R.M. Kelly: AIChE J., 1986, vol. 32, pp. 1920–3.

14 S.W.P.M. Van, J.C. Charpentier, and J. Villermaux: Chem. Eng. Sci., 1969, vol. 24, pp. 1083–95.

15 A. Janzen, M. Schubert, F. Barthel, U. Hampel, and E.Y. Kenig: Chem. Eng. Process. Process Intensif., 2013, vol. 66, pp. 20–6.

16 A. Janzen, J. Steube, S. Aferka, E.Y. Kenig, M. Crine, P. Marchot, and D. Toye: Chem. Eng. Sci., 2013, vol. 102, pp. 451–60.

W.M. Husslage, M. A. Reuter, R.H. Heerema, T. Bakker, and G.S. Steeghs: Metall. Mater. Trans. B 2005, vol. 36, pp. 765–76.

18 N. Standish: Chem. Eng. Sci., 1968, vol. 23, pp. 51–6.

19 N. Standish: Chem. Eng. Sci., 1968, vol. 23, pp. 945–7.

20 A.E. Sáez, M.M. Yépez, C. Cabrera, and E.M. Soria: AIChE J., 1991, vol. 37, pp. 1733–6.

21 H. Kawabata, Z. Liu, F. Fujita, and T. Usui: ISIJ Int., 2005, vol. 45, pp. 1466–73.

22 Y. Sato, T. Hirose, F. Takahashi, M. Toda, T. Hirose, and Y. Hashiguchi: J. Chem. Eng. JAPAN, 1973, vol. 6, pp. 315–9.

23 Y. Eto, K. Takeda, and S. Taguch: ISIJ Int., 1993, vol. 33, pp. 681–6.

24 G.X. Wang, D.Y. Liu, J.D. Lister, A.B. Yu, S.J. Chew, and P. Zulli: Chem. Eng. Sci., 1997, vol. 52, pp. 4013–9.

25 S. Natsui, K.I. Ohno, S. Sukenaga, T. Kikuchi, and R.O. Suzuki: ISIJ Int., 2018, vol. 58, pp. 282–91.

26 S. Natsui, H. Nogami, S. Ueda, J. Kano, R. Inoue, and T. Ariyama: ISIJ Int., 2011, vol. 51, pp. 41–50.

27 T. Ariyama, S. Natsui, T. Kon, S. Ueda, S. Kikuchi, and H. Nogami: ISIJ Int., 2014, vol. 54, pp. 1457–71.

28 D.D. Geleta, I.H. Siddiqui, and J. Lee: Metall. Mater. Trans. B, 2020, vol. 51, pp. 102–13.

Dong XF, Jayasekara A, Sert D, Ferreira R, Gardin P, Monaghan BJ, Chew SJ, Pinson D, Zulli P (2020) Metall. Mater. Trans. B 1:11 https://doi.org/10.1007/s11663-020-02009-1

30 L.H. George, B.J. Monaghan, R. Longbottom, and P.R. Austin: ISIJ Int., 2011, vol. 53, pp. 1172–9.

31 H.L. George, R.J. Longbottom, S.J. Chew, and B.J. Monaghan: ISIJ Int., 2014, vol. 54, pp. 820–6.

32 I. Jeong, H. Kim, and Y. Sasaki: ISIJ Int., 2013, vol. 53, pp. 2090–8.

33 I. Jeong and S. Jung: ISIJ Int., 2016, vol. 56, pp. 537–45.

Harris CK, Kotteda VMK, Shantha-kumar S, Kumar V, Bronson A (2021) Metall. Mater. Trans. B 1:11 https://doi.org/10.1007/s11663-021-02065-1

35 G.J. Kramer: Chem. Eng. Sci., 1998, vol. 53, pp. 2985–92.

36 A.E. Sáez and R.G. Carbonell: J. Colloid Interface Sci., 1990, vol. 140, pp. 408–18.

37 E. Bayramli, A. Abou-Obeid, and T.G.M. Van De Ven: J. Colloid Interface Sci., 1987, vol. 116, pp. 490–502.

P.S. Laplace: Méchanique Céleste, 1806.

39 Z.S. Mao, T.Y. Xiong, and J. Chen: Chem. Eng. Sci., 1993, vol. 48, pp. 2697–703.

40 S. Ghosh, N.N. Viswanathan, and N.B. Ballal: Chem. Eng. Sci., 2020, vol. 212, pp. 115332–40.

41 M.A. Erle, D.C. Dyson, and N.R. Morrow: AIChE J., 1971, vol. 17, pp. 115–21.

S. Ghosh, N.B. Ballal, and N.N. Viswanathan: Metall. Mater. Trans. B 2020, 46:1–27.

S. Ghosh, N.N. Viswanathan, and N.B. Ballal: in Proceedings for the 8th International Conference on Modeling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM 2019, 2019, pp. 160–67.

44 S. Iliev and N. Pesheva: J. Colloid Interface Sci., 2006, vol. 301, pp. 677–84.

45 S.D. Iliev: J. Colloid Interface Sci., 1997, vol. 194, pp. 287–300.

46 G.A. Turner and G.F. Hewitt: Trans. Instn. Chem. Engrs, 1959, vol. 37, pp. 329–324.

47 C.W. Extrand and A.N. Gent: J. Colloid Interface Sci., 1990, vol. 138, pp. 431–42.

A. Rohatgi: (http://arohatgi.info/WebPlotDigitizer/app/Accessed June 2 2014.), 2020, pp. 1–17.

49 R.G. Picknett and R. Bexon: J. Colloid Interface Sci., 1977, vol. 61, pp. 336–50.

M. Namadi: M.Tech Thesis, Indian Institute of Tecnology Bombay, 2020.

51 R.F. Benenati and C.B. Brosilow: AIChE J., 1962, vol. 8, pp. 359–61.

52 A. de Klerk: AIChE J., 2003, vol. 49, pp. 2022–9.

53 M. Suzuki, H. Kada, and M. Hirota: Adv. Powder Technol., 1999, vol. 10, pp. 353–65.

54 G. Mason and W. Clark: Nature, 1965, vol. 207, p. 512.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 13, 2020, accepted April 1, 2021.

Rights and permissions

About this article

Cite this article

Ghosh, S., Erram, A., Namadi, M. et al. The Efficacy of a Three-Dimensional Static Liquid–Vapor Interface Model to Calculate the Static Liquid Holdup of a Packed Bed. Metall Mater Trans B 52, 2072–2086 (2021). https://doi.org/10.1007/s11663-021-02167-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02167-w