Abstract

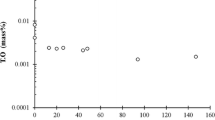

Existing standards for the characterization of the size, morphology, chemistry, and distribution of inclusions in steels using different techniques are briefly reviewed in this work. Strengths and shortfalls of different methods are discussed, and a combination of different criteria is used to quantitatively characterize the inclusions in a continuously cast high-carbon steel. It is shown that the main elements in the inclusions for the studied steel were Mn, S, Ti, Al, and oxygen and that alongside MnS and some Al2O3 inclusions many non-metallic inclusions appeared in complex forms, consisting of silicates, sulfides, and different types of oxides. Duplex inclusions, mainly cores of Al2O3, or SiO2 surrounded by MnS were the most common complex multiphase inclusions in this steel. An industrial approach was used to classify the inclusions into thirteen different oxide types. Based upon this approach, data are presented according to the chemistry of inclusions using diagrams featuring different quantitative parameters. Furthermore, it is shown that the number of oxides per unit area and the size of oxides, respectively, decreased and increased with increasing distance from the surface of the bloom which had solidified at the highest cooling rate.

Similar content being viewed by others

References

D.J. Dyson, A.J. Rose, M.M. Whitwood, and D.P. Wilcox: Ironmaking Steelmaking, 1998, vol. 25, No. 4, pp. 279-286.

Johansson S (1988) in: J.J.C. Hoo (ed) Effect of Steel Manufacturing Processes on the Quality of Bearing Steels. Baltimore: ASTM, pp. 250–262.

German Standard Microscopical Examination of Special Steels for Non-Metallic Inclusions Using Standard Micrograph Charts (VDEh 1570-71).

ASTM E 45-97, in Standard Test Methods for Determining the Inclusion Content of Steel, ASM International, Materials Park.

D.J. Dyson, A.J. Rose, M.M. Whitwood, and D. P. Wilcox: Clean Steel 5: Fifth International Conference on Clean Steel, Vol. 2, Balatonfured, Hungary, 2–4 June 1997, pp. 68–78.

E 2142-01 Standard Test Methods for Rating and Classifying Inclusions in Steel Using the Scanning Electron Microscope.

ISO 4967: 1998 (E) “Steel—Determination of Content of Nonmetallic Inclusions—Micrographic Method Using Standard Diagrams”. D-type inclusions based on ISO 4967 are non-deformable and stress-raisers, which have aspect ratio of less than 3:1.

BS EN 10247:2007, Micrographic Examination of the Non-metallic Inclusion Content of Steels Using Standard Pictures.

Bearing Steels: The Rating of Nonmetallic Inclusion, By J. J. C. Hoo Page 6, ASTM International, 1975.

M.-A. Van Ende, M. X. Guo, E. Zinngrebe, R. Dekkers, J. Proost, B. Blanpain, P. Wollants (2009) Ironmaking and Steelmaking 36: 201-208.

M. Nuspl, W. Wegscheider, J. Angeli, W. Posch, and M. Mayr: Anal. Bioanal. Chem., 2004, 379, pp. 640-645.

J.C. Ross (2002) The Image Processing Handbook, 4th ed. CRC Press, Boca Raton, p. 513.

M.T. Shehata, “Characterization of Particle Dispersion”, Practical Guide to Image Analysis, ASM International, Materials Park, 2000, pp. 129-144.

S. Mizoguchi and T. Tamamura: 6th International Iron and Steel Congress, Vol. 3, Steelmaking I, Nagoya, ISIJ, 1990, pp. 598–604.

K. Oikawa, K. Ishida and T. Nishizawa: ISIJ Int., 1997, vol. 37, pp. 332-338.

M. Wakoh, T. Sawai and S. Mizoguchi: ISIJ Int., 1996, vol. 36, pp. 1014-1021.

H. Goto, K. Miyazawa, K. Yamamuchi, S. Ogibayashi and T. Tanaka: ISIJ Int., 1994, vol. 34, pp. 414-419.

S. Abraham, J. Raines, and R. Bodnar: 2013 AISTech Conference Proceedings, Association for Iron & Steel Technology, Pittsburgh, 6–9 May 2013, vol. 1, pp. 1069–84.

S. Mizoguchi: Ph. D. thesis, The University of Tokyo, 1996.

T.A. Tran and R.P. Thackray: 2012 AISTech Conference Proceedings, Association for Iron & Steel Technology, Atlanta, 7–10 May 2012, pp. 1221–1228.

Acknowledgments

The authors would like to thank the Engineering and Physical Sciences Research Council (EPSRC) for funding this project and Tata Steel UK for supplying the material, the use of automated SEM facilities, and their in-house chemistry analysis spreadsheet package. The help of Dr. Andrew Rose from Tata Steel UK is very much appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 16, 2013.

Rights and permissions

About this article

Cite this article

Faraji, M., Wilcox, D.P., Thackray, R. et al. Quantitative Characterization of Inclusions in Continuously Cast High-Carbon Steel. Metall Mater Trans B 46, 2490–2502 (2015). https://doi.org/10.1007/s11663-015-0442-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0442-7