Abstract

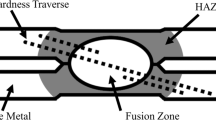

This paper investigates process–microstructure–performance relationships in Q&P980 third-generation advanced high-strength steel (AHSS) resistance spot welds. The hardening and softening phenomena during welding are discussed in terms of weldment microstructure. The fusion zone (FZ) microstructure was mainly lath martensite with an average hardness of 500 HV due to the high cooling rate resulting from resistance spot welding. No significant softening was observed in the sub-critical heat-affected zone which was related mainly to the presence of the low volume fraction of fresh martensite in the initial microstructure of the base metal. The factors controlling the tensile–shear peak load, failure energy, and failure mode transition of Q&P980 resistance spot welds are discussed. The assessment of the tensile–shear peak load of the welds failed in the IF mode verified that interfacial failure strength is governed by FZ hardness rather than FZ fracture toughness. In the case of pullout failure, two competing failure mechanisms were identified: (i) ductile cracking from the notch tip and (ii) through-thickness localized necking, with the former was found to be the dominant failure mechanism for the Q&P980 steel resistance spot welds. The high susceptibility of the Q&P980 resistance spot welds to interfacial mode was due to its low hardening ratio, lack of significant softening in the HAZ, and its propensity to shrinkage void formation.

Similar content being viewed by others

References

M.Y. Demeri: Advanced High-Strength Steels: Science, Technology, and Applications, ASM International, Materials Park, 2013.

E. Billur: Hot Stamping of Ultra High-Strength Steels. From a Technological and Business Perspective, Springer, Cham, 2019.

M. Tisza: Lect. Notes Mech. Eng., 2021, vol. 22, pp. 81–94.

J.G. Speer, E. De Moor, K.O. Findley, D.K. Matlock, and B.C. De Cooman: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3591–3601.

L. Wang and J.G. Speer: Metallogr. Microstruct. Anal., 2013, vol. 2, pp. 268–81.

J. Speer, D.K. Matlock, B.C. De Cooman, and J.G. Schroth: Acta Mater., 2003, vol. 51, pp. 2611–22.

E.J. Seo, L. Cho, and B.C. De Cooman: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 3797–3802.

E. de Moor, S. Lacroix, A.J. Clarke, J. Penning, and J.G. Speer: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2586–95.

M. Pouranvari and S.P.H. Marashi: Sci. Technol. Weld. Join., 2013, vol. 18, pp. 361–403.

M. Pouranvari, H.R. Asgari, S.M. Mosavizadch, and P.H. Marashi: Sci. Technol. Weld. Join., 2007, vol. 12, pp. 217–25.

B. Wang, Q.Q. Duan, G. Yao, J.C. Pang, X.W. Li, L. Wang, and Z.F. Zhang: Int. J. Fatigue., 2014, vol. 66, pp. 20–28.

T. Chen, Z. Ling, M. Wang, and L. Kong: Mater. Sci. Eng. A, 2022, vol. 831, 142164.

T. Chen, Z. Ling, M. Wang, and L. Kong: J. Mater. Process. Technol., 2020, vol. 285, 116797.

B. Figueredo, D.C. Ramachandran, A. Macwan, and E. Biro: Weld. World., 2021, vol. 65, pp. 2359–69.

M.J. Santofimia, L. Zhao, R. Petrov, C. Kwakernaak, W.G. Sloof, and J. Sietsma: Acta Mater., 2011, vol. 59, pp. 6059–6068.

B.C. De Cooman, J.G. Speer, and M. Trip: Steel Res. Int., 2006, vol. 77, pp. 634–40.

F. HajyAkbary, J. Sietsma, G. Miyamoto, T. Furuhara, and M.J. Santofimia: Acta Mater., 2016, vol. 104, pp. 72–83.

K.E. Easterling: Mathematical Modelling of Weld Phenomena, eds. H. Cerjak, K.E. Easterling, The Institute of Materials, London. 1993, pp. 183–200.

J.E. Gould, S.P. Khurana, and T. Li: Weld. J., 2006, vol. 85, pp. 111s–116s.

M. Pouranvari and S.P.H. Marashi: Mater. Sci. Technol., 2009, vol. 25, pp. 1411–16.

M. Pouranvari and S.P.H. Marashi: Ironmak. Steelmak., 2012, vol. 39, pp. 104–11.

M. Pouranvari, S.P.H. Marashi, and D.S. Safanama: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8344–52.

M. Pouranvari: Can. Metall. Q., 2012, vol. 51, pp. 67–74.

M.S. Khan, S.D. Bhole, D.L. Chen, E. Biro, G. Boudreau, and J. Van Deventer: Sci. Technol. Weld. Join., 2009, vol. 14, pp. 616–25.

S. Brauser, L.A. Pepke, G. Weber, and M. Rethmeier: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7099–7108.

I.A. Soomro and S.R. Pedapati: Int. J. Adv. Manuf. Technol., 2019, vol. 105, pp. 3249–60.

X. Long and S.K. Khanna: Int. J. Fatigue, 2007, vol. 29, pp. 879–86.

M. Pouranvari and S.P.H. Marashi: Sci. Technol. Weld. Join, 2010, vol. 15, pp. 149–55.

C. Ma, D.L. Chen, S.D. Bhole, G. Boudreau, A. Lee, and E. Biro: Mater. Sci. Eng. A, 2008, vol. 485, pp. 334–46.

A. Ramazani, K. Mukherjee, A. Abdurakhmanov, M. Abbasi, and U. Prahl: Metals (Basel)., 2015, vol. 5, pp. 1704–16.

H. Rezayat: The Role of Heterogeneous Constitutive Properties on Mechanical Behavior of Advanced High Strength Steel Spot Welds, PhD Dissertation, University of Tennessee, 2019.

V. Hernandez: Effects of Martensite Tempering on HAZ-Softening and Tensile Properties of Resistance Spot Welded Dual-Phase Steels, PhD Thesis, University of Waterloo, 2010.

M. Khan: Spot welding of advanced high strength steels (AHSS), Master Thesis, University of Waterloo, 2007.

M.M.H. Abadi and M. Pouranvari: Mater. Tehnol., 2014, vol. 48, pp. 67–71.

Y.S. Zhang, H.T. Sun, G.L. Chen, and X.M. Lai: Proc. Inst. Mech. Eng. Part B, 2009, vol. 223, pp. 1341–50.

R. Koganti, S. Angotti, A. Wexler, and D.F. Maatz: SAE Tech. Pap., No. 2008-01-1113, 2008.

J. Pakkanen, R. Vallant, and M. Kičin: Weld. World., 2016, vol. 60, pp. 393–402.

L. Prém, Z. Bézi, and A. Balogh: Adv. Mater. Res., 2016, vol. 1138, pp. 43–48.

R. Koganti, S. Angotti, A. Joaquin, T. Coon, A. Wexler, and C. Orsette: SAE Tech. Pap, No. 2009-01-0805, 2009.

S. Dancette, D. Fabrègue, V. Massardier, J. Merlin, T. Dupuy, and M. Bouzekri: Eng. Fail. Anal., 2012, vol. 25, pp. 112–22.

H. Wu, B. Zhao, H. Gao, Z.B. Zhao, and C. Liu: Appl. Mech. Mater., 2015, vol. 789–790, pp. 15–19.

V.H.B. Hernandez, Y. Okita, and Y. Zhou: Weld. J., 2012, vol. 91, pp. 278s–285s.

H. ErtekEmre and B. Bozkurt: Eng. Fail. Anal., 2020, vol. 110, p. 104439.

S. Ao, H. Shan, X. Cui, Z. Luo, Y.J. Chao, and M. Ma: Weld. World., 2016, vol. 60, pp. 1095–1107.

K. Chung, W. Noh, X. Yang, H.N. Han, and M.G. Lee: Int. J. Plast., 2017, vol. 94, pp. 122–47.

S.T. Wei, D. Lv, R.D. Liu, L. Lin, R.J. Xu, J.Y. Guo, and K.Q. Wang: Sci. Technol. Weld. Join., 2014, vol. 19, pp. 427–35.

S. Zhang, C. DiGiovanni, L. He, and N.Y. Zhou: Sci. Technol. Weld. Join., 2020, vol. 26, pp. 58–67.

I. Hajiannia, M. Shamanian, M. Atapour, R. Ashiri, and S.A.E. Int: J. Mater. Manuf., 2018, vol. 12, pp. 4–18.

M. Shojaee, A.R.H. Midawi, B. Barber, H. Ghassemi-armaki, M. Worswick, and E. Biro: J. Manuf. Process., 2021, vol. 65, pp. 364–72.

X.D. Liu, Y.B. Xu, R.D.K. Misra, F. Peng, Y. Wang, and Y.B. Du: J. Mater. Process. Technol., 2019, vol. 263, pp. 186–97.

C. Luo and Y. Zhang: In MATEC Web Conf., 2019, vol. 269, p. 03002. EDP Sciences.

M. Pouranvari, S. Sobhani, and F. Goodarzi: J. Manuf. Process., 2018, vol. 31, pp. 867–74.

M. Tamizi, M. Pouranvari, and M. Movahedi: Sci. Technol. Weld. Join., 2017, vol. 22, pp. 327–35.

Y. Li, H. Tang, and R. Lai: Processes, 2021, vol. 9, p. 1021.

H. Ghassemi-Armaki, E. Biro, and S. Sadagopan: ISIJ Int., 2017, vol. 57, pp. 1451–60.

J.K. Larsson: In proceeding of EUROJOIN 8., 2012, Pula, Croatia.

N. Tan, J. Hong, M. Lei, X. Jin, H. Zheng, and Z. Luo: Sci. Technol. Weld. Join., 2020, vol. 25, pp. 525–34.

Y. Lu, A. Peer, T. Abke, M. Kimchi, and W. Zhang: Mater. Des., 2018, vol. 155, pp. 170–84.

Y.S. Jong, Y.K. Lee, D.C. Kim, M.J. Kang, I.S. Hwang, and W.B. Lee: Mater. Trans., 2011, vol. 52, pp. 1330–33.

G. Janardhan, G. Mukhopadhyay, K. Kishore, and K. Dutta: J. Mater. Eng. Perform., 2020, vol. 29, pp. 3383–94.

A. Mohamadizadeh, E. Biro, and M. Worswick: Eng. Fract. Mech., 2022, vol. 268, 108506.

S. Acharya and K.K. Ray: Mater. Sci. Eng. A, 2013, vol. 565, pp. 405–13.

S.S. Rao, R. Chhibber, K.S. Arora, and M. Shome: J. Mater. Process. Technol., 2017, vol. 246, pp. 252–61.

G. Mukhopadhyay, S. Bhattacharya, and K.K. Ray: Mater. Des., 2009, vol. 30, pp. 2345–54.

U. Ozsarac: J. Mater. Eng. Perform., 2012, vol. 21, pp. 748–55.

D.C. Saha, S.S. Nayak, E. Biro, A.P. Gerlich, and Y. Zhou: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 6153–62.

M. Shamsujjoha, C.M. Enloe, A.C. Chuang, and J.J. Coryell: Materialia, 2020, vol. 15, 100975.

M. Tamizi, M. Pouranvari, and M. Movahedi: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 655–67.

M.I. Khan, M.L. Kuntz, and Y. Zhou: Sci. Technol. Weld. Join., 2008, vol. 13, pp. 294–304.

M. Xia, E. Biro, Z. Tian, and Y.N. Zhou: ISIJ Int., 2008, vol. 48, pp. 809–14.

I.O. Yilmaz, A.Y. Bilici, and H. Aydin: J. Cent. South Univ., 2019, vol. 26, pp. 25–42.

S. Dancette, V. Massardier-Jourdan, D. Fabrègue, J. Merlin, T. Dupuy, and M. Bouzekri: ISIJ Int., 2011, vol. 51, pp. 99–107.

H. Rezayat, H. Ghassemi-armaki, and S.S. Babu, In proceedings of Trends in Welding Research, Proceedings of the 10th International Conference, Tokyo, Japan, 2016.

C. Rajarajan, P. Sivaraj, and V. Balasubramanian: Mater. Res. Express., 2020, vol. 7, 016555.

F. Nikoosohbat, S. Kheirandish, M. Goodarzi, M. Pouranvari, and S.P.H. Marashi: Mater. Sci. Technol., 2010, vol. 26, pp. 738–44.

W. Guo, Z. Wan, P. Peng, Q. Jia, G. Zou, and Y. Peng: J. Mater. Process. Tech., 2018, vol. 256, pp. 229–38.

W. Li, L. Ma, P. Peng, Q. Jia, Z. Wan, Y. Zhu, and W. Guo: Mater. Sci. Eng. A, 2018, vol. 717, pp. 124–33.

D. Chandran, B. Figueredo, O. Sherepenko, W. Jin, Y. Park, and E. Biro: J. Manuf. Process., 2022, vol. 75, pp. 320–30.

O. Sherepenko and S. Jüttner: Weld. World, 2019, vol. 63, pp. 151–59.

O. Sherepenko, A. Mohamadizadeh, A. Zvorykina, M. Worswick, E. Biro, and S. Jüttner: J. Mater. Sci., 2021, vol. 56, pp. 14287–97.

O. Sherepenko, O. Kazemi, P. Rosemann, M. Wilke, T. Halle, and S. Jüttner: Metals, 2019, vol. 10, p. 10.

Y. Zhang, W. Xu, G. Zhang, W. Tao, and S. Yang: Metall. Mater. Trans. A, 2022, vol. 53A, pp. 794–809.

Y.B. Li, D.L. Li, S.A. David, Y.C. Lim, and Z. Feng: Sci. Technol. Weld. Join., 2016, vol. 21, pp. 555–63.

D.S. Safanama, S.P.H. Marashi, and M. Pouranvari: Sci. Technol. Weld. Join., 2012, vol. 17, pp. 288–94.

M. Pouranvari and S.P.H. Marashi: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8337–43.

A.G. Kalashami, C. Digiovanni, M.H. Razmpoosh, F. Goodwin, and N.Y. Zhou: J. Manuf. Process., 2020, vol. 57, pp. 370–79.

ANSI/AWS/SAE Standard D8.9-97.

JIS Z 3140, japanese Ind. Stand. Committee, Tokyo, Japan.

D.J. Radakovic and M. Tumuluru: Weld. J., 2008, vol. 87, pp. 96–105.

M. Pouranvari: Sci. Technol. Weld. Join., 2018, vol. 23, pp. 520–26.

M. Pouranvari: Mater. Sci. Eng. A, 2012, vol. 546, pp. 129–38.

S. Zhang: Int. J. Fract., 1997, vol. 88, pp. 167–85.

D. Radaj: Design and Analysis of Fatigue Resistant Welded Structures, Woodhead Publishing, Abington, 1990.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nadimi, N., Yadegari, R. & Pouranvari, M. Resistance Spot Welding of Quenching and Partitioning (Q&P) Third-Generation Advanced High-Strength Steel: Process–Microstructure–Performance. Metall Mater Trans A 54, 577–589 (2023). https://doi.org/10.1007/s11661-022-06903-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06903-y