Abstract

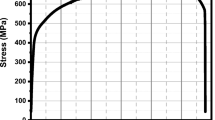

The microstructure evolution of Q&P 980 steel resistance spot welds under two different welding conditions, i.e., single pulse and dual pulse, and the influence of the welding process on the mechanical strength and fracture behavior of welds were investigated. The welds had a softening zone inside the subcritical heat-affected zone (SC-HAZ) for both welding conditions. Moreover, a Mn-free zone (approximately 20 μm in width) leading to the formation of a banded bainite microstructure with a lower microhardness between the fusion zone (FZ) and the HAZ was observed, causing cracks to initiate under single pulse welding. Compared to the single pulse process, the dual pulse process with a suitable secondary current and an in situ post-weld heat treatment effect leads to an enhancement in tensile-shear and cross-tensile mechanical properties. By establishing the relationship between the microstructure of the failure path, including the FZ, Mn-free zone, and HAZ, and the mechanical properties, the mechanism of mechanical property improvement was revealed. After introducing the post-weld current, three strengthening mechanisms for the FZ were observed, i.e., tempered martensite, refined martensite, and remelted nugget. Moreover, in situ pulse welding caused a new softening phenomenon in the HAZ and led to the transformation of the banded bainite into martensite in the Mn-free zone, causing changes in the fracture mode and improvement in the mechanical properties.

Similar content being viewed by others

References

J. Speer, D.K. Matlock, B.C. De Cooman, and J.G. Schroth: Acta Mater., 2003, vol. 51, pp. 2611–22.

M. Pouranvari: World Appl. Sci. J., 2011, vol. 15, pp. 1454–8.

S. Morito, X. Huang, T. Furuhara, T. Maki, and N. Hansen: Acta Mater., 2006, vol. 54, pp. 5323–31.

D. Shirmohammadi, M. Movahedi, and M. Pouranvari: Mater. Sci. Eng. A., 2017, vol. 703, pp. 154–61.

M. Mimer, L.E. Svensson, and R. Johansson: Weld. World., 2004, vol. 48, pp. 14–8.

C. Wakabayashi, S. Furusako, and Y. Miyazaki: Sci. Technol. Weld. Join., 2015, vol. 20, pp. 468–72.

A. Chabok, E. van der Aa, J.T.M. De Hosson, and Y.T. Pei: Mater. Des., 2017, vol. 124, pp. 171–82.

C. Sawanishi, T. Ogura, K. Taniguchi, R. Ikeda, K. Oi, K. Yasuda, and A. Hirose: Sci. Technol. Weld. Join., 2014, vol. 19, pp. 52–9.

V.H.B. Hernandez, Y. Okita, and Y. Zhou: Weld. J., 2012, vol. 91, pp. 278–85.

P. Eftekharimilani, E.M. van der Aa, M.J.M. Hermans, and I.M. Richardson: Sci. Technol. Weld. Join., 2017, vol. 22, pp. 545–54.

X.D. Liu, Y.B. Xu, R.D.K. Misra, F. Peng, Y. Wang, and Y.B. Du: J. Mater. Process. Technol., 2019, vol. 263, pp. 186–97.

B. Wang, Q.Q. Duan, G. Yao, J.C. Pang, X.W. Li, L. Wang, and Z.F. Zhang: Int. J. Fatigue., 2014, vol. 66, pp. 20–8.

C.L. Fan, B.H. Ma, D.N. Chen, H.R. Wang, and D.F. Ma: Chin. Phys. Lett., 2016, vol. 33, pp. 3–8.

W. Li, L. Ma, P. Peng, Q. Jia, Z. Wan, Y. Zhu, and W. Guo: Mater. Sci. Eng. A., 2018, vol. 717, pp. 124–33.

M. Pouranvari and S.P.H. Marashi: Sci. Technol. Weld. Join., 2013, vol. 18, pp. 361–403.

J.E. Gould, S.P. Khurana, and T. Li: Weld. J., 2006, vol. 85, pp. 111–6.

M. Amirthalingam, E.M. van der Aa, C. Kwakernaak, M.J.M. Hermans, and I.M. Richardson: Weld. World., 2015, vol. 59, pp. 743–55.

M. Pouranvari: Mater. Sci. Eng. A., 2012, vol. 546, pp. 129–38.

X. Liao, X. Wang, Z. Guo, M. Wang, Y. Wu, and Y. Rong: Mater. Charact., 2010, vol. 61, pp. 341–6.

I. Madariaga and I. Gutiérrez: Acta Mater., 1999, vol. 47, pp. 951–60.

S. Sajjadi-Nikoo, M. Pouranvari, A. Abedi, and A.A. Ghaderi: Sci. Technol. Weld. Join., 2018, vol. 23, pp. 71–8.

P. Eftekharimilani, E.M. van der Aa, M.J.M. Hermans, and I.M. Richardson: Weld. World., 2017, vol. 61, pp. 691–701.

J. Hidalgo and M.J. Santofimia: Metall. Mater. Trans. A., 2016, vol. 47A, pp. 5288–301.

Z. Guo, C.S. Lee, and J.W. Morris: Acta Mater., 2004, vol. 52, pp. 5511–8.

J.J. Jonas: Mater. Sci. Forum., 2013, vol. 753, pp. 546–53.

Y. You, C. Shang, N. Wenjin, and S. Subramanian: Mater. Sci. Eng. A., 2012, vol. 558, pp. 692–701.

S. Li, S. Yang, Q. Lu, H. Luo, and W. Tao: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 1–9. https://doi.org/10.1007/s11663-018-1463-9.

H. Zhang, X. Qiu, F. Xing, J. Bai, and J. Chen: Mater. Des., 2014, vol. 55, pp. 366–72.

R.W. Rathbun, D.K. Matlock, and J.G. Speer: Weld. J., 2003, vol. 82, pp. 207–18.

Acknowledgments

This work was supported by The State Key Laboratory of Rolling and Automation (No. 2018RALKFKT009).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 10, 2021; accepted November 8, 2021.

Rights and permissions

About this article

Cite this article

Zhang, Y., Xu, W., Zhang, G. et al. Mechanical Behavior and Failure Mechanism of Q&P980 Steel During In Situ Post-Weld Heat Treatment (PWHT) Resistance Spot Welding. Metall Mater Trans A 53, 794–809 (2022). https://doi.org/10.1007/s11661-021-06546-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06546-5