Abstract

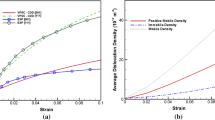

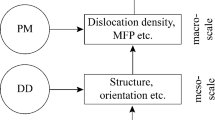

The constitutive behavior of metallic materials in terms of dislocation kinetics can be successfully described using a dislocation density-based model. Although the kinetics of thermally activated plastic deformation is well described by such models, the number of material constants associated with the model leads to non-unique solution set. In the present work, transient stress relaxation test is used to identify rate-dependent material parameters. The stress relaxation test, when used in conjunction with stress–strain curve can reduce the uncertainty associated with parameter identification. The proposed methodology is demonstrated using aluminum alloys subjected to severe plastic deformation processes such as cryorolling and constrained groove pressing. Kocks–Mecking–Estrin (KME) dislocation density model is implemented as a user subroutine in commercial finite element analysis software. The parameter identification procedure is validated by comparing the experimental results of monotonic tensile and limiting dome height tests. Using dislocation density model, it is shown that unlike the general understanding, the limiting strain is not related to the strain hardening exponent. The limiting strain correlates only with the extent of dynamic recovery, a component of strain hardening.

Similar content being viewed by others

Change history

28 March 2022

A Correction to this paper has been published: https://doi.org/10.1007/s11661-022-06665-7

Notes

The immobile dislocation density changes with \(\sigma _i\). Since \(\sigma _i\) is almost constant, the variation of total dislocation density during stress relaxation is similar to that of mobile dislocation density.

References

H.J. Kleemola and M.A. Nieminen: Metall. Trans., 1974, vol. 5, pp. 1863–66.

S. Sudhy, K. Panicker, S. Prasad, S. Basak, and S.K. Panda: J. Mater. Eng. Perform., 2017, vol. 26, pp. 3954–69.

E.I. Poliak and J.J. Jonas: Acta Mater., 1996, vol. 44, pp. 127–36.

E.W. Hart: J. Eng. Mater. Technol., 1976, vol. 98, pp. 193–202.

J.C. Swearengen and R.W. Rhode: Metall. Trans. A., 1977, vol. 8, pp. 577–82.

Y. Bergström, Y. Granbom, and D. Sterkenburg: J. Metall., 2010, vol. 2010, pp. 647198(1–16).

U.F. Kocks and H. Mecking: Prog. Mater. Sci., 2003, vol. 48, pp. 171–273.

U.F. Kocks: J. Eng. Mater. Technol., 1976, vol. 98, pp. 76–85.

Y. Estrin: J. Mater. Process. Technol., 1998, vol. 80, pp. 33–9.

Y. Estrin: in Unified Constitutive Laws of Plastic Deformation. A.S. Krausz and K. Krausz, eds., Academic Press, New York City, 1996, pp. 69–106.

A. Vinogradov, E. Agletdinov, I.S. Yasnikov, K. Mathis, and Y. Estrin: Mater. Sci. Eng. A, 2020, vol. 780, pp. 139194(1–12).

G.-H. Zhao, X. Xu, D. Dye, and P.E.J. Rivera-Díaz-del-Castillo: Acta Mater., 2020, vol. 183, pp. 155–64.

N. Ueshima, K. Kubota, and K. Oikawa: Materialia, 2019, vol. 8, pp. 100464(1–9).

C. Fressengeas, A.J. Beaudoin, M. Lebyodkin, L.P. Kubin, and Y. Estrin: Mater. Sci. Eng. A., 2005, vol. 400–401, pp. 226–30.

Y. Estrin and H. Mecking: Acta Metall., 1984, vol. 32, pp. 57–70.

Y. Estrin, L.S. Tóth, A. Molinari, and Y. Bréchet: Acta Mater., 1998, vol. 46, pp. 5509–22.

E.F. Rauch, J.J. Gracio, and F. Barlat: Acta Mater., 2007, vol. 55, pp. 2939–48.

Y. Estrin, H. Braasch, and Y. Brechet: J. Eng. Mater. Technol., 1996, vol. 118, pp. 441–47.

A. Prabhakar, G.C. Verma, H. Krishnasamy, P.M. Pandey, M.G. Lee, and S. Suwas: Mech. Res. Commun., 2017, vol. 85, pp. 76–80.

B. Meng, B.N. Cao, M. Wan, C.J. Wang, and D.B. Shan: Int. J. Mech. Sci., 2019, vol. 157–158, pp. 609–18.

Z. Yao, G.-Y. Kim, Z. Wang, L.A. Faidley, Q. Zou, D. Mei, and Z. Chen: Int. J. Plast., 2012, vol. 39, pp. 75–87.

H. Krishnaswamy, M.J. Kim, S.-T. Hong, D. Kim, J.-H. Song, M.-G. Lee, and H.N. Han: Mater. Des., 2017, vol. 124, pp. 131–42.

M.N. Shetty: Dislocations and Mechanical Behaviour of Materials, PHI Learning Pvt. Ltd., Delhi, 2013, pp. 326–495.

J. Schlipf: Mater. Sci. Eng., 1986, vol. 77, pp. 19–26.

Y. Estrin and L.P. Kubin: Acta Metall., 1986, vol. 34, pp. 2455–64.

L.P. Kubin and Y. Estrin: Acta Metall. Mater., 1990, vol. 38, pp. 697–708.

Y. Bergström: Mater. Sci. Eng., 1970, vol. 5, pp. 193–200.

B. Babu and L.-E. Lindgren: Int. J. Plast., 2013, vol. 50, pp. 94–108.

A. Molinari and G. Ravichandran: Mech. Mater., 2005, vol. 37, pp. 737–52.

K. Changela, H. Krishnaswamy, and R.K. Digavalli: Metall. Mater. Trans. A., 2020, vol. 51A, pp. 648–66.

R. Valiev: Nat. Mater., 2004, vol. 3, pp. 511–16.

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Prog. Mater. Sci., 2000, vol. 45, pp. 103–89.

A. Vinogradov, S. Yasuoka, and S. Hashimoto: Mater. Sci. Forum., 2008, vol. 584–586, pp. 797–802.

K. Changela, H. Krishnaswamy, and R.K. Digavalli: Mater. Sci. Eng. A., 2019, vol. 760, pp. 7–18.

S. Kumar, H. Krishnaswamy, R.K. Digavalli, and S.K. Paul: J. Manuf. Process., 2019, vol. 38, pp. 49–62.

D. Torre, E.V. Pereloma, and C.H.J. Davies: Scripta Mater., 2004, vol. 51, pp. 367–71.

F. Diologent, R. Goodall, and A. Mortensen: Acta Mater., 2011, vol. 59, pp. 6869–79.

S. Lee, S.-J. Lee, and B.C. De Cooman: Acta Mater., 2011, vol. 59, pp. 7546–53.

M.S. Mohebbi, A. Akbarzadeh, Y.-O. Yoon, and S.-K. Kim: Mech. Mater., 2015, vol. 89, pp. 23–34.

F.H. Dalla Torre, E.V. Pereloma, and C.H.J. Davies: Acta Mater., 2006, vol. 54, pp. 1135–46.

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma: Mater. Sci. Eng. A., 2004, vol. 381, pp. 71–9.

M. Moradpour, F. Khodabakhshi, and H. Eskandari: Mater. Sci. Technol., 2004, vol. 34, pp. 1003–17.

C. Chinthanai Selvan, C. Sathiya Narayanan, B. Ravisankar, R. Narayanasamy, and C. Thillaiyadi Valliammai: Mater. Res. Express, 2020, vol. 7, pp. 036525(1–11).

P. Wang, T. Yin, and Qu. Shaoxing: Scripta Mater., 2020, vol. 178, pp. 171–75.

C. Zheng and L. Li: Mater. Sci. Eng. A., 2018, vol. 713, pp. 35–42.

M. Montazeri-Pour and M.H. Parsa: Mech. Mater., 2016, vol. 94, pp. 117–31.

H. Conrad: Mater. Sci. Eng., 1970, vol. 6, pp. 265–73.

H. Conrad: Prog. Mater. Sci., 1981, vol. 26, pp. 123–403.

F. Barlat, M.V. Glazov, J.C. Brem, and D.J. Lege: Int. J. Plast., 2002, vol. 18, pp. 919–39.

U.F. Kocks, A.S. Argon, and M.F. Ashby: Prog. Mater. Sci., 1975, vol. 19, pp. 68–109.

D. Caillard and J.L. Martin: Pergamon Mater. Ser., 2003, vol. 8, pp. 57–82.

C.A. Howard and R.J. Stokes: Proc. R. Soc. Lond. A., 1955, vol. 233, pp. 17–34.

Z.S. Basinski: Philos. Mag., 1958, vol. 4, pp. 393–432.

D.L. Holt: J. Appl. Phys., 1970, vol. 41, pp. 3197–201.

H. Krishnaswamy and F. Barlat: Metall. Mater. Trans. A., 2019, vol. 50A, pp. 513–17.

S.H. He, K.Y. Zhu, and M.X. Huang: Comput. Mater. Sci., 2017, vol. 131, pp. 1–10.

S.K. Panigrahi and R. Jayaganthan: Mater. Sci. Eng. A., 2011, vol. 528, pp. 3147–60.

R.Z. Valiev, N.A. Enikeev, MYu. Murashkin, V.U. Kazykhanov, and X. Sauvage: Scripta Mater., 2010, vol. 63, pp. 949–52.

F. Guiu and P.L. Pratt: Phys. Status Solidi B., 1964, vol. 6, pp. 111–20.

P. Feltham: Philos. Mag., 1961, vol. 6, pp. 847–50.

J. Bonneville, P. Spätig, and J.L. Martin: MRS Online Proc. Libr., 1994, vol. 364, pp. 369–74.

A. Varma, H. Krishnaswamy, J. Jain, M.-G. Lee, and F. Barlat: Mech. Mater., 2019, vol. 133, pp. 138–53.

P.M. Anderson, J.P. Hirth, and J. Lothe: Theory of Dislocations, 3rd ed. Cambridge University Press, New York, 2017, pp. 413–54.

X.-S. Yang, Y.-J. Wang, G.-Y. Wang, H.-R. Zhai, L.H. Dai, and T.-Y. Zhang: Acta Mater., 2016, vol. 108, pp. 252–63.

I.-C. Choi, Y.-J. Kim, B. Ahn, M. Kawasaki, T.G. Langdon, and J.-i Jang: Scripta Mater., 2014, vol. 75, pp. 102–05.

Y. Xiao, B. Gan, A. S. Sologubenko, R. Spolenak, and J.M. Wheeler: Mater. Sci. Eng. A, 2021, vol. 800, pp. 140266(1–8).

Y.M. Wang, A.V. Hamza, and E. Ma: Appl. Phys. Lett., 2005, vol. 86, pp. 241917(1–3).

R.W. Hayes, D. Witkin, F. Zhou, and E.J. Lavernia: Acta Mater., 2004, vol. 52, pp. 4259–71.

H. Krishnaswamy and J. Jain: Manuf. Lett., 2020, vol. 26, pp. 64–68.

T. Kruml, O. Coddet, and J.L. Martin: Acta Mater., 2008, vol. 56, pp. 333–40.

K. Sunil Kumar, H. Krishnaswamy, and R.K. Digavalli: Mater. Manuf. Processes., 2020, vol. 35, pp. 687–99.

S. Kumar, S. Venkatachalam, H. Krishnaswamy, R.K. Digavalli, and H.S.N. Murthy: J. Eng. Mater. Technol., 2019, vol. 141, pp. 041007(1–10).

K. Hashiguchi: Elastoplasticity Theory, 2nd ed. Springer, Berlin Heidelberg, 2014, pp. 379–420.

D.R. Satish, F. Feyissa, and D.R. Kumar: Mater. Manuf. Processes., 2017, vol. 32, pp. 1345–52.

B. Modi and D.R. Kumar: Int. J. Adv. Manuf. Technol., 2013, vol. 66, pp. 1159–69.

H. Krishnaswamy, P. Dubey, and J. Jain: Mater. Sci. Eng. A., 2016, vol. 673, pp. 250–56.

L. Yong and Z. Jingchuan: Mech. Mater., 2008, vol. 40, pp. 792–95.

S. Mishra, V.K. Beura, A. Singh, and M. Yadava: Metall. Mater. Trans. A., 2019, vol. 50A, pp. 3472–77.

L. Xiao and J.L. Bai: Mater. Sci. Eng. A., 1998, vol. 244, pp. 250–56.

A. Varma, A. Gokhale, J. Jain, H. Krishnaswamy, P. Cizek, and M. Barnett: Philos. Mag., 2018, vol. 255, pp. 165–81.

K. Prasad, H. Krishnaswamy, and J. Jain: J. Mater. Process. Technol., 2018, vol. 98, pp. 1–7.

Y. Wang, Y. Liu, and J.T. Wang: Mater. Sci. Eng. A., 2015, vol. 635, pp. 86–93.

R.J. Asaro and S. Suresh: Acta Mater., 2005, vol. 635, pp. 3369–82.

Y.M. Wang, A.V. Hamza, and E. Ma: Acta Mater., 2006, vol. 54, pp. 2715–26.

C.X. Huang, W.P. Hu, and Q.Y. Wang: Mater. Sci. Eng. A., 2014, vol. 611, pp. 274–79.

Q. Wei: J. Mater. Sci., 2007, vol. 42, pp. 1709–27.

S.S.S. Kumar and T. Raghu: Mater. Des., 2014, vol. 57, pp. 114–20.

Z. Horita, M. Furukawa, M. Nemoto, A.J. Barnes, and T.G. Langdon: Acta Mater., 2000, vol. 48, pp. 3633–40.

A. Dhal, S.K. Panigrahi, and M.S. Shunmugam: J. Alloys Compd., 2017, vol. 726, pp. 1205–19.

I.S. Yasnikov, A. Vinogradov, and Y. Estrin: Scripta Mater., 2014, vol. 76, pp. 37–40.

S. Kumar, P.P. Date, and K. Narasimhan: J. Mater. Process. Technol., 1994, vol. 45, pp. 583–88.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Myoung Gyu Lee's given name was corrected.

Appendices

Appendix I: UMAT algorithm

-

1.

Values at previous steps (nth step):

-

Stress components at nth step: \({\underline{\sigma }}_n\)

-

Logarithmic strain components at nth step: \({\underline{\varepsilon }}_n\)

-

Plastic strain components at nth step: \({\underline{\varepsilon }}^p_n\)

-

Effective plastic strain at nth step: \(p_n\)

-

Dislocation density at nth step: \(\rho _n\)

-

-

2.

Increment in logarithmic (true) strain components \( \Delta {\underline{\varepsilon }}_{n+1} \) is given by ABAQUS FEA software based on the time step and displacement boundary conditions (Linearly ramped over the total step time).

-

3.

Compute elastic predictor:

-

\({\underline{\sigma }}^{(0)}_{n+1} = {\underline{\sigma }}_{n} + \underline{{\underline{E}}}.\Delta {\underline{\varepsilon }}_{n+1}\) where \(\underline{{\underline{E}}}\) is the elastic stiffness matrix.

-

\({\underline{\varepsilon }}_{n+1}^{p(0)} = {\underline{\varepsilon }}_{n}^{p}\)

-

\(p^{(0)}_{n+1} = p_n\)

-

\(\rho ^{(0)}_{n+1} = \rho _n\)

Then calculate predictor Von Mises equivalent stress and predictor yield stress values,

-

\(\bar{\sigma }^{(0)}_{n+1} = \phi ({\underline{\sigma }}^{(0)}_{n+1})\)

-

\((\sigma _y)^{(0)}_{n+1} = f(\rho _{n+1}^{(0)}) = C \sqrt{\rho _{n+1}^{(0)}}\)

-

-

4.

Check if Yield condition is satisfied.

Predictor yield function, \(F_{n+1}^{(0)} = \bar{\sigma }^{(0)}_{n+1} - (\sigma _y)^{(0)}_{n+1}\)

If \(F^{(0)}_{n+1} < 0\), then material is in elastic regime, set the trial state to be the final state.

-

\({\underline{\sigma }}_{n+1} = {\underline{\sigma }}^{(0)}_{n+1}\)

-

\({\underline{\varepsilon }}^{p}_{n+1} = {\underline{\varepsilon }}^{p(0)}_{n+1}\)

-

\(p_{n+1} = p^{(0)}_{n+1}\)

-

\(\rho _{n+1} = \rho ^{(0)}_{n+1}\)

Begin next Cycle from Step 1.

If \(F^{(0)}_{n+1} \ge 0\), then the material has yielded. Proceed to next step.

-

-

5.

Commence the newton iteration. Set iteration no. \(k=0\) and \(\Delta p^{(0)}_{n+1} = 0\), \(\Delta \rho ^{(0)}_{n+1} = 0\)

From Radial Return Algorithm for Von Mises,

$$\begin{aligned} \bar{\sigma }_{n+1} = \bar{\sigma }^{(0)}_{n+1} - 3G\Delta p_{n+1} \end{aligned},$$(A1)where G is the Shear Modulus of the material.

$$\begin{aligned} (\sigma _y)_{n+1}= & f(\rho _{n+1}) = f(\rho _n + \Delta \rho _{n+1}) = f(\Delta \rho _{n+1}) \nonumber \\= & f(\Delta p_{n+1}) \end{aligned}.$$(A2)$$\begin{aligned} \therefore F^{(k)}_{n+1}= & \bar{\sigma }^{(k)}_{n+1} - (\sigma _y)^{(k)}_{n+1} = \bar{\sigma }^{(0)}_{n+1} - 3G\Delta p^{(k)}_{n+1} \nonumber \\&- (\sigma _y)^{(k)}_{n+1} = F(\Delta p^{(k)}_{n+1}) \end{aligned}.$$(A3)By Newton Raphson method,

$$\begin{aligned} \Delta p^{(k+1)}_{n+1}= & \Delta p^{(k)}_{n+1} + d\Delta p^{(k+1)}_{n+1}\nonumber \\ \text {where }\,d\Delta p^{(k+1)}_{n+1}= & - \dfrac{F(\Delta p^{(k)}_{n+1})}{F^{'}(\Delta p^{(k)}_{n+1})} = \dfrac{\bar{\sigma }^{(0)}_{n+1} - 3G\Delta p^{(k)}_{n+1} - (\sigma _y)_{n+1}^{(k)}}{3G + \dfrac{\partial (\sigma _y)_{n+1}^{(k)}}{\partial \Delta p^{(k)}_{n+1}}} \end{aligned},$$(A4)$$\begin{aligned} (\sigma _y)_{n+1}^{(k)}= &C \sqrt{\rho _{n+1}^{(k)}} = C \sqrt{\rho _{n} + \Delta \rho _{n+1}^{(k)}} \end{aligned},$$(A5)By chain rule,

$$\begin{aligned} \dfrac{\partial (\sigma _y)_{n+1}^{(k)}}{\partial \Delta p^{(k)}_{n+1}}= & \dfrac{\partial (\sigma _y)_{n+1}^{(k)}}{\partial \Delta \rho ^{(k)}_{n+1}} * \dfrac{\partial \Delta \rho _{n+1}^{(k)}}{\partial \Delta p^{(k)}_{n+1}} \end{aligned},$$(A6)$$\begin{aligned} \dfrac{\partial (\sigma _y)_{n+1}^{(k)}}{\partial \Delta \rho ^{(k)}_{n+1}}= & \dfrac{C}{2 \sqrt{\rho _n + \Delta \rho ^{(k)}_{(n+1)}}} \nonumber \\ \dfrac{\partial (\sigma _y)_{n+1}^{(k)}}{\partial \Delta \rho ^{(k)}_{n+1}}= & \dfrac{C}{2 \sqrt{\rho _n + \Delta \rho ^{(k)}_{(n+1)}}} \end{aligned},$$(A7)$$\begin{aligned} \therefore d\Delta p^{(k+1)}_{n+1}= & \dfrac{\bar{\sigma }^{(0)}_{n+1} - 3G\Delta p^{(k)}_{n+1} - C \sqrt{\rho _{n} + \Delta \rho _{n+1}^{(k)}}}{3G + \dfrac{C M\left[ K_0 + K\left( 1-\exp \left( {-\psi \sqrt{\rho _n + \Delta \rho ^{(k)}_{(n+1)}}}\right) \right) - K_2\left( \rho _n + \Delta \rho _{n+1}^{(k)}\right) \right] }{2 \sqrt{\rho _n + \Delta \rho ^{(k)}_{(n+1)}}}} \end{aligned}.$$(A8)To calculate \( \Delta \rho ^{(k+1)}_{n+1}\), we use Euler’s method of Forward marching for Initial Value Problems,

$$\begin{aligned} \Delta \rho ^{(k+1)}_{n+1}= & \Delta \rho ^{(k)}_{n+1} + \left( \dfrac{\partial \Delta \rho ^{(k)}_{n+1}}{\partial \Delta p^{(k)}_{n+1}}\right) *d\Delta\Delta p^{(k+1)}_{n+1} \end{aligned},$$(A9)$$\begin{aligned} (\sigma _y)^{(k+1)}_{n+1}= & f(\rho ^{(k+1)}_{n+1}) = f(\rho _n + \Delta \rho ^{(k+1)}_{n+1}) = C \sqrt{\rho _{n} + \Delta \rho _{n+1}^{(k+1)}} \end{aligned},$$(A10)$$\begin{aligned} F^{(k+1)}_{n+1}= & \bar{\sigma }^{(0)}_{n+1} - 3G\Delta p^{(k+1)}_{n+1} - (\sigma _y)^{(k+1)}_{n+1} \end{aligned}.$$(A11)The iteration continues till the value of \(F^{(k+1)}_{n+1}\) reduces below a tolerance value say \(10^{-6}\).

Then \(\Delta p_{n+1} = \Delta p^{(k+1)}_{n+1}\) and \(\Delta \rho _{n+1} = \Delta \rho ^{(k+1)}_{n+1}\)

-

6.

Update increments in plastic strain components

$$\begin{aligned} \Delta {\underline{\varepsilon }}^{(p)}_{n+1} = \Delta p_{n+1}\dfrac{\partial \phi _{(n+1)}}{\partial {\underline{\sigma }}_{n+1}} = \dfrac{3}{2} \Delta p_{(n+1)} \dfrac{{\underline{S}}^{(0)}_{(n+1)}}{ {\bar{\sigma }}^{(0)}_{n+1}} \text {(Applicable\,\, for\, \,Von\,\, Mises\,\, yield\,\, criterion)} \end{aligned},$$(A12)where \({\underline{S}}_{(n+1)}\) represents the Deviatoric Stress components.

-

7.

Update new values of Stress components, effective plastic strain, and dislocation density

\({\underline{\sigma }}_{n+1} = {\underline{\sigma }}_{n} + \underline{{\underline{E}}}.(\Delta {\underline{\varepsilon }}_{n+1} - \Delta {\underline{\varepsilon }}^{(p)}_{n+1})\)

\( p_{n+1}=p_{n}+\Delta p_{n+1} \)

\( \rho _{n+1}=\rho _{n}+\Delta \rho _{n+1} \)

-

8.

Jacobian Matrix for Von Mises under Radial Return Algorithm

$$\begin{aligned} \underline{{\underline{J}}} = \underline{{\underline{E}}}-\frac{(\underline{{\underline{E}}}\cdot {\underline{n}}) \times (\underline{{\underline{E}}}\cdot {\underline{n}})}{{\underline{n}} \cdot (\underline{{\underline{E}}} \cdot {\underline{n}})+h} \end{aligned},$$(A13)where \({\underline{n}} = \frac{\partial \phi _{n+1}}{\partial {\underline{\sigma }}_{n+1}}=\frac{3}{2}*\frac{{\underline{S}}^{(0)}_{(n+1)}}{{\bar{\sigma }}^{(0)}_{n+1}}\)

and \(h = \frac{\partial (\sigma _y)_{n+1}}{\partial p_{n+1}} = \frac{\partial (\sigma _y)_{n+1}}{\partial \rho _{n+1}}\frac{\partial \rho _{n+1}}{\partial p_{n+1}}= \frac{C}{2\sqrt{\rho _{n+1}}}M\left[ K_{0}+K\left( 1-\exp (-\psi \sqrt{\rho _{n+1}})\right) - K_{2}\rho _{n+1}\right]. \)

Appendix II: Method for Least-Square Fitting of Modified KME Model Parameters

Upon identifying the rate-dependent constants \({\dot{\varepsilon }}_0\) and m as explained in Section II–C, the remaining constants C, \(K_0\), K, \(K_2\) and \(\psi \) can be estimated by fitting the experimental true stress–true plastic strain data using least-square method. In the present work, an open source software ‘SCILAB’ is used for the purpose.

From equations 4 and 7, using chain rule,

Eliminating \(\rho \) by substituting \(\rho = \left( \dfrac{\sigma }{C}\right) ^2\), we obtain

At zero plastic strain (\(\varepsilon = 0\)), \(\sigma (0)= \sigma _0\), the initial yield stress, which is available from the experimental data. Thus, the above equation gives the evolution of stress with plastic strain in the form of an initial value ODE.

The error function for this problem is the sum of the squares of the differences between the ODE solution and the experimental values of true stress.

The minimization of this error function gives us the optimum values of the parameters \(C,\,K_0,\,K,\,K_2\) and \(\psi \). The set of initial guess values for all the parameters are iterated over a range to ensure that the solution of curve fitting is consistent.

Appendix III: Sample MATLAB Code

See Fig. A1.

Rights and permissions

About this article

Cite this article

Balaji, V., Kumar, S., Krishnaswamy, H. et al. Transient Stress Relaxation Test to Identify Material Constants in Dislocation Density Model. Metall Mater Trans A 53, 1969–1990 (2022). https://doi.org/10.1007/s11661-022-06624-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06624-2