Abstract

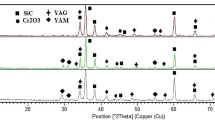

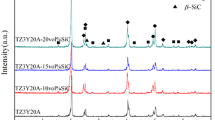

In this work, α-SiC ceramics with aluminum or yttria sintering additives ranging from 1.0 to 4.0 wt pct were prepared by hot pressing, and the effect of sintering additives on the microstructure and mechanical properties of SiC ceramics was investigated. Specimens with Al additive exhibited fully dense microstructure with relative density > 99.4 pct. However, the relative density of specimens with Y2O3 decreases constantly from 99.5 to 95.7 pct as Y2O3 content increases, which is possibly due to the formation of gaseous phase and evaporation of volatile compounds resulting from the chemical reaction between SiC matrix and Y2O3 additive. X-ray diffraction (XRD) and Raman spectra results showed that Al addition leads to the transformation from 6H to 4H polytypes, and the transformation degree increases as increasing the Al content, while no obvious polytype transformation is observed for specimens with Y2O3 additive. Scanning electron microscopy (SEM) observations revealed that specimens with Y2O3 are composed of equiaxed grains with average size about 1.0 μm, whereas the specimens with Al additive exhibit larger grain size with partly elongated grain structure. Additionally, it is found that the grain growth of specimens with Al addition is accompanied by the polytype transformation. Further analysis revealed that, for specimens with Al additive, enhanced grain size and formation of elongated of SiC grains lead to an improvement in fracture toughness from 5.7 to 7.1 MPa m1/2 but a slight decline in flexural strength from 706 to 632 MPa. The crack deflection and bridging as well as undesirable stress effects related to the large elongated grains are responsible for the variation in mechanical properties. In the case of SiC sintered with Y2O3, there are obvious declines in flexural strength and fracture toughness from 714 to 492 MPa and from 5.9 to 3.4 MPa m1/2, respectively, which are mainly attributed to the increased porosity. The impact of Al and Y2O3 on the microstructure and mechanical properties of SiC ceramics was discussed.

Similar content being viewed by others

References

H. Ghezelbash, A. Zeinali, N. Ehsani, and H.R. Baharvandi: J. Aust. Ceram. Soc., 2019, vol. 55, pp. 903–11.

K.J. Kim, K.Y. Lim, and Y.W. Kim: J. Eur. Ceram. Soc., 2012, vol. 32, pp. 4401–6.

A. Noviyanto and D.H. Yoon: Curr. Appl. Phys., 2013, vol. 13, pp. 287–92.

B.Z. Su, H.Q. Liang, G.L. Liu, Z.R. Huang, X.J. Liu, Z.M. Chen, and D.Y.W. Yu: J. Eur. Ceram. Soc., 2018, vol. 38, pp. 2289–96.

A. Noviyanto, S.W. Han, H.W. Yu, and D.H. Yoon: J. Eur. Ceram. Soc., 2013, vol. 33, pp. 2915–23.

M. Martínez, C.R. Miguel, D.R. Arturo, O.L. Angel, and G. Fernando: J. Am. Ceram. Soc., 2007, vol. 90, pp. 163–9.

K. Negita: J. Am. Ceram. Soc., 1986, vol. 69, pp. C308–10.

A. Noviyanto and D.H. Yoon: Mater. Res. Bull., 2011, vol. 46, pp. 1186–91.

P. Sahani, S.K. Karak, B. Mishra, D. Chakravarty, and D. Chaira: Int. J. Refract. Met. Hard Mater.., 2016, vol. 57, pp. 31–41.

N. Zhang, H.Q. Ru, Q.K. Cai, and X.D. Sun: Mater. Sci. Eng. A., 2008, vol. 486, pp. 262–6.

J.H. She and K. Ueno: Mater. Res. Bull., 1999, vol. 34, pp. 1629–36.

D. Cheong, J. Kim, and S.J.L. Kang: J. Eur. Ceram. Soc., 2002, vol. 22, pp. 1321–7.

Y.W. Kim, S.H. Jang, T. Nishimura, S.Y. Choi, and S.D. Kim: J. Eur. Ceram. Soc., 2017, vol. 37, pp. 4449–55.

Y.W. Kim, K.J. Kim, H.C. Kim, N.H. Cho, and K.Y. Lim: J. Am. Ceram. Soc., 2011, vol. 94, pp. 991–3.

K.Y. Lim, Y.W. Kim, and K.J. Kim: Ceram. Int., 2014, vol. 40, pp. 10577–82.

S. Gupta, S.K. Sharma, B.V.M. Kumar, and Y.W. Kim: Ceram. Int., 2015, vol. 41, pp. 14780–9.

J. Ihle, M. Herrmann, and J. Adler: J. Eur. Ceram. Soc., 2005, vol. 25, pp. 997–1003.

K. Biswas: Mater. Sci. Forum., 2009, vol. 624, pp. 71–89.

D. Chen, M.E. Sixta, X.F. Zhang, L.C. De Jonghe, and R.O. Ritchie: Acta Mater., 2000, vol. 48, pp. 4599–608.

H. Tanaka, H.N. Yoshimura, S. Otani, Y. Zhou, and M. Toriyama: J. Am. Ceram. Soc., 2000, vol. 83, pp. 226–8.

M. Moslemi, M. Razavi, M. Zakeri, M.R. Rahimipour, and M. Schreiner: Phase. Transit., 2018, vol. 91, pp. 733–41.

W. Guo, H. Xiao, J. Liu, J. Liang, P. Gao, and G. Zeng: Ceram. Int., 2015, vol. 41, pp. 11117–24.

Z. Li, W. Zhou, X. Su, F. Luo, D. Zhu, and P. Liu: J. Am. Ceram. Soc., 2008, vol. 91, pp. 2607–10.

L.U. Ogbuji, T.E. Mitchell, and A.H. Heuer: J. Am. Ceram. Soc., 1981, vol. 64, pp. 91–9.

Y. Zhou, H. Tanaka, S. Otani, and Y. Bando: J. Am. Ceram. Soc., 1999, vol. 82, pp. 1959–64.

S.I. Nakashima, M. Higashihira, K. Maeda, and H. Tanaka: J. Am. Ceram. Soc., 2003, vol. 86, pp. 823–9.

K.J. Kim, K.Y. Lim, Y.W. Kim, M.J. Lee, and W.S. Seo: J. Eur. Ceram. Soc., 2014, vol. 34, pp. 1695–701.

Z.A. Yaşar and R.A. Haber: Materials., 2020, vol. 13, p. 3768.

Y.W. Kim and J.G. Lee: J. Mater. Sci., 1992, vol. 27, pp. 4746–50.

J.K. Lee, J.G. Park, E.G. Lee, D.S. Seo, and Y. Hwang: Mater. Lett., 2002, vol. 57, pp. 203–8.

T. Grande, H. Sommerset, E. Hagen, K. Wiik, and M.A. Einarsrud: J. Am. Ceram. Soc., 1997, vol. 80, pp. 1047–52.

S.K. Lee and C.H. Kim: J. Am. Ceram. Soc., 1994, vol. 77, pp. 1655–8.

K. Raju and D.H. Yoon: Ceram. Int., 2016, vol. 42, pp. 17947–62.

J.C. Viala, P. Fortier, and J. Bouix: J. Mater. Sci., 1990, vol. 25, pp. 1842–50.

C. Chen, X. Han, H. Shen, Y. Tan, H. Zhang, Y. Qin, and S.M. Peng: Ceram. Int., 2020, vol. 46, pp. 23173–9.

Y. Huang, D. Jiang, X. Zhang, Z. Liao, and Z. Huang: J. Eur. Ceram. Soc., 2018, vol. 38, pp. 4329–37.

Z.N. Wing: J. Eur. Ceram. Soc., 2017, vol. 37, pp. 1373–8.

Y. Hirata, N. Suzue, N. Matsunaga, and S. Sameshima: J. Eur. Ceram. Soc., 2010, vol. 30, pp. 1945–54.

Y.K. Seo, Y.W. Kim, K.J. Kim, and W.S. Seo: J. Eur. Ceram. Soc., 2016, vol. 36, pp. 3879–87.

H.J. Yeom, Y.W. Kim, and K.J. Kim: J. Eur. Ceram. Soc., 2015, vol. 35, pp. 77–86.

Y.H. Kim, Y.W. Kim, K.Y. Lim, and S.J. Lee: J. Eur. Ceram. Soc., 2019, vol. 39, pp. 144–9.

G.D. Kim and Y.W. Kim: J. Eur. Ceram. Soc., 2021, vol. 41, pp. 3980–90.

G.D. Zhan, M. Mitomo, and Y.W. Kim: J. Am. Ceram. Soc., 1999, vol. 82, pp. 2924–6.

R. Sedlák, A. Koval Líková, V. Girman, E. Múdra, P. Rutkowski, A. Dubiel, and J. Dusza: J. Eur. Ceram. Soc., 2017, vol. 37, pp. 4307–14.

C.S. Lee, Y.W. Kim, D.H. Cho, H.B. Lee, and H.J. Lim: Ceram. Int., 1998, vol. 24, pp. 489–95.

Y.W. Kim, M. Mitomo, and H. Hirotsuru: J. Am. Ceram. Soc., 1995, vol. 78, pp. 3145–8.

Y.W. Kim, M. Mitomo, and H. Hirotsuru: J. Am. Ceram. Soc., 1997, vol. 80, pp. 99–105.

S. Kultayeva and Y.W. Kim: Ceram. Int., 2020, vol. 46, pp. 19264–73.

J.K. Li, X.P. Ren, Y.L. Zhang, and H.L. Hou: J. Mater. Res. Technol., 2020, vol. 9, pp. 33–41.

H. Liang, X. Yao, Z. Huang, Y. Zeng, and B. Su: J. Eur. Ceram. Soc., 2016, vol. 36, pp. 1863–71.

Y.T. Liu, Z. Chen, R.Z. Liu, J. Zhao, and M. Liu: Ceram. Int., 2020, vol. 46, pp. 24504–11.

Z.W. Qin, Y.M. Xie, X.C. Meng, D.L. Qian, J.C. Li, C. Li, J. Cao, L. Wan, and Y.X. Huang: ACS Appl. Mater. Interfaces., 2021, vol. 13, pp. 34385–96.

Y.M. Xie, X.C. Meng, Y.L. Li, D.X. Mao, L. Wang, and Y.X. Huang: Compos. Commun., 2021, vol. 26, p. 100776.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China under Grant no. 11505247, the Strategic Priority Research Program of the Chinese Academy of Sciences under Grant no. XDA21010202, the Program of the Innovation Center of Nuclear Materials for National Defense Industry of China under Grant no. ICNM-2021-ZH-09 and the Joint Funds of the National Natural Science Foundation of China under grant no. U1832206. The authors sincerely thank Dr. Lijuan Niu and Dr. Shufen Li of IMPCAS for sample polishing and XRD characterization.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Y., Qin, Z., Chai, J. et al. Effects of Sintering Additives on Microstructure and Mechanical Properties of Hot-Pressed α-SiC Ceramics. Metall Mater Trans A 53, 1188–1199 (2022). https://doi.org/10.1007/s11661-021-06554-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06554-5