Abstract

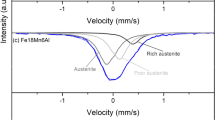

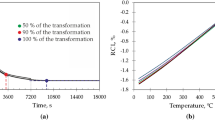

The microstructural evolution of the two austenitic alloys Fe–20Mn–3Al–0.7C wt pct and Fe–20Mn–6Al–0.7C wt pct when different thermal and thermomechanical treatments are performed has been studied. To this end, a generic industrial die of 100 ton capacity and a Gleeble 3800 simulator were selected to perform the thermomechanical treatments. A solubilization treatment was carried out at 1100 °C for 4 days for the two alloys in as cast state. In addition, the specimens deformed with the industrial die underwent a solubilization treatment at 1100 °C for 4 hours. Microstructural characterizations were performed by X-ray diffraction, transmission Mössbauer spectrometry, and electron backscatter diffraction. The results showed both the formation of different austenites rich and poor in solute atoms, as well as different microstructures, as a function of the treatments performed, which affected the resulting dynamically recrystallized microstructures. Notably, it was observed that it is possible to explain and relate the evolution of the microstructure to the hyperfine parameters resulting from fitting the Mössbauer spectra. In particular, the relationship between the degree of dynamic recrystallization and the evolution of an ordered austenitic structure is discussed.

Similar content being viewed by others

Abbreviations

- SEM:

-

Scanning electron microscopy

- XRD:

-

X-ray diffraction

- TMS:

-

Transmission Mössbauer spectroscopy

- EBSD:

-

Electron backscatter diffraction

- MS:

-

Mössbauer spectra

- TWIP:

-

Twinning induced plasticity

- TRIP:

-

Transformation induced plasticity

- ID:

-

Industrially deformed

- SFE:

-

Stacking fault energy

- S-4d:

-

Solubilized for 4 days

- DL:

-

Deformed in the laboratory

- OES:

-

Optical emission spectroscopy

- TIS-4h:

-

Thermomechanical industrial treated and then solubilized for 4 hours

- HMFD:

-

Hyperfine magnetic field distribution

- XRF:

-

X-ray fluorescence

- EDXS:

-

Energy-dispersive X-ray spectroscopy

References

G. Frommeyer, E.J. Drewes, and B. Engl: Revue Métall.., 2000, vol. 97, pp. 1245–53. https://doi.org/10.1051/metal:2000110.

G. Frommeyer, U. Brüx, and P. Neumann: ISIJ Int., 2003, vol. 43, pp. 438–46. https://doi.org/10.2355/isijinternational.43.438.

D. Hao, D. Hua, C.L. Qiu, Z.Y. Tang, J.M. Zeng, and Y. Ping: J. Iron Steel Res. Int., 2011, vol. 18, pp. 36–40. https://doi.org/10.1016/S1006-706X(11)60008-3.

B.C. De Cooman, Y. Estrin, and S.K. Kim: Acta Mater., 2018, vol. 142, pp. 283–362. https://doi.org/10.1016/j.actamat.2017.06.046.

W. Song, T. Ingendahl, and W. Bleck: Acta Metall.Sin. (Engl Lett.)., 2014, vol. 27, pp. 546–56. https://doi.org/10.1007/s40195-014-0084-9.

S. Chen, R. Rana, A. Haldar, and R.K. Ray: Prog. Mater Sci., 2017, vol. 89, pp. 345–91. https://doi.org/10.1016/j.pmatsci.2017.05.002.

S.L. Wong, M. Madivala, U. Prahl, F. Roters, and D. Raabe: Acta Mater., 2016, vol. 118, pp. 140–51. https://doi.org/10.1016/j.actamat.2016.07.032.

F. Abu-Farha, X. Hu, X. Sun, Y. Ren, L.G. Hector, G. Thomas, and T.W. Brown: Metall. Mater. Trans. A., 2018, vol. 49A, pp. 2583–96. https://doi.org/10.1007/s11661-018-4660-x.

K. Sato, M. Ichinose, Y. Hirotsu, and Y. Inoue: ISIJ Int., 1989, vol. 29, pp. 868–77. https://doi.org/10.2355/isijinternational.29.868.

O. Grässel, G. Frommeyer, C. Derder, and H. Hofmann: J. Phys. IV JP., 1997, vol. 7, pp. 1–6. https://doi.org/10.1051/jp4:1997560.

H. Kim, D.W. Suh, and N.J. Kim: Sci. Technol. Adv. Mater., 2013, vol. 14, pp. 1–12. https://doi.org/10.1088/1468-6996/14/1/014205.

O.A. Zambrano: J. Mater. Sci., 2018, vol. 53, pp. 14003–62. https://doi.org/10.1007/s10853-018-2551-6.

O.A. Zambrano: J. Eng. Mater. Technoll.Trans. ASME., 2016, vol. 138, pp. 1–10. https://doi.org/10.1115/1.4033632.

I. Gutierrez-Urrutia and D. Raabe: Acta Mater., 2012, vol. 60, pp. 5791–802. https://doi.org/10.1016/j.actamat.2012.07.018.

J.D. Yoo and K.T. Park: Mater. Sci. Eng. A., 2008, vol. 496, pp. 417–24. https://doi.org/10.1016/j.msea.2008.05.042.

E. Welsch, D. Ponge, S.M. Hafez Haghighat, S. Sandlöbes, P. Choi, M. Herbig, S. Zaefferer, and D. Raabe: Acta Mater., 2016, vol. 116, pp. 188–99. https://doi.org/10.1016/j.actamat.2016.06.037.

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck: Metall. Mater. Trans. A., 2009, vol. 40A, pp. 3076–90. https://doi.org/10.1007/s11661-009-0050-8.

Y. Lee and C. Choi: Metall. Mater. Trans. A., 2000, vol. 31A, pp. 355–60. https://doi.org/10.1007/s11661-000-0271-3.

J. Zhang, D. Raabe, and C.C. Tasan: Acta Mater., 2017, vol. 141, pp. 374–87. https://doi.org/10.1016/j.actamat.2017.09.026.

M. Eskandari, M.A. Mohtadi-Bonab, A. Zarei-Hanzaki, and S.M. Fatemi: J. Mater. Eng. Perform., 2018, vol. 27, pp. 1555–69. https://doi.org/10.1007/s11665-018-3273-2.

B.B. He, B.M. Huang, S.H. He, Y. Qi, H.W. Yen, and M.X. Huang: Mater. Sci. Eng. A., 2018, vol. 724, pp. 11–6. https://doi.org/10.1016/j.msea.2018.03.065.

M. Klimova, S. Zherebtsov, N. Stepanov, G. Salishchev, C. Haase, and D.A. Molodov: Mater. Charact., 2017, vol. 132, pp. 20–30. https://doi.org/10.1016/j.matchar.2017.07.043.

W. Wu, Y.W. Wang, P. Makrygiannis, F. Zhu, G.A. Thomas, L.G. Hector, X. Hu, X. Sun, and Y. Ren: Mater. Sci. Eng. A., 2018, vol. 711, pp. 611–23. https://doi.org/10.1016/j.msea.2017.11.008.

O. Grässel, L. Krüger, G. Frommeyer, and L.W. Meyer: Int. J. Plast., 2000, vol. 16, pp. 1391–409. https://doi.org/10.1016/S0749-6419(00)00015-2.

D. Li, Y. Feng, Z. Yin, F. Shangguan, K. Wang, Q. Liu, and F. Hu: Mater. Des., 2012, vol. 34, pp. 713–8. https://doi.org/10.1016/j.matdes.2011.05.031.

Y.F. Shen, Y.D. Wang, X.P. Liu, X. Sun, R. Lin Peng, S.Y. Zhang, L. Zuo, and P.K. Liaw: Acta Mater., 2013, vol. 61, pp. 6093–106. https://doi.org/10.1016/j.actamat.2013.06.051.

O.A. Zambrano, J. Valdés, Y. Aguilar, J.J. Coronado, S.A. Rodriguez, and R.E. Logé: Mater. Sci. Eng. A., 2017, vol. 689, pp. 269–85. https://doi.org/10.1016/j.msea.2017.02.060.

O.A. Zambrano and R.E. Logé: Mater. Charact., 2019, vol. 152, pp. 151–61. https://doi.org/10.1016/j.matchar.2019.04.016.

W.-C. Cheng, C.-Y. Cheng, C.-W. Hsu, and D.E. Laughlin: Mater. Sci. Eng. A., 2015, vol. 642, pp. 128–35. https://doi.org/10.1016/j.msea.2015.06.096.

G.M. Barona Osorio, G.A. Pérez, J. Ramos, J.F. Durán, P.C. Astudillo, A.F. Soriano, and H. Sánchez Sthepa: Hyperfine Interact., 2017, vol. 238, p. 56. https://doi.org/10.1007/s10751-017-1422-x.

K. Sato, K. Tagawa, and Y. Inoue: Mater. Sci. Eng. A., 1989, vol. 111, pp. 45–50. https://doi.org/10.1016/0921-5093(89)90196-2.

G.D. Tsay, Y.H. Tuan, C.L. Lin, C.G. Chao, and T.F. Liu: Mater. Trans., 2011, vol. 52, pp. 521–5. https://doi.org/10.2320/matertrans.M2010255.

L.N. Bartlett, D.C. Van Aken, J. Medvedeva, D. Isheim, N.I. Medvedeva, and K. Song: Metall. Mater. Trans. A., 2014, vol. 45A, pp. 2421–35. https://doi.org/10.1007/s11661-014-2187-3.

V.H.C. de Albuquerque, E. de Macedo Silva, J. Pereira Leite, E.P. de Moura, V.L. de Araújo Freitas, and J.M.R.S. Tavares: Mater. Design., 2010, vol. 31, pp. 2147–50. https://doi.org/10.1016/j.matdes.2009.11.010.

E. Murad: Handbook of Clay Science, vol. 5, 2013, pp. 11–24. https://doi.org/10.1016/B978-0-08-098259-5.00003-2.

C. Paduani, E. Da Silva, and G.A. Pérez-Alcázar: Hyperfine Interact., 1992, vol. 73, pp. 233–45. https://doi.org/10.1007/BF02418598.

J. Ramos, J.F. Piamba, H. Sánchez, and G.A. Pérez: Hyperfine Interact., 2015, vol. 232, pp. 119–26. https://doi.org/10.1007/s10751-015-1127-y.

O.A. Zambrano, J. Valdés, L.A. Rodriguez, D. Reyes, E. Snoeck, S.A. Rodríguez, and J.J. Coronado: Tribol. Int., 2019, vol. 135, pp. 421–31. https://doi.org/10.1016/j.triboint.2019.03.002.

F. Varret and J. Teillet: Université du Maine (France).

B.H. Toby: J. Appl. Crystallogr., 2001, vol. 34, pp. 210–3. https://doi.org/10.1107/S0021889801002242.

ASTM: E92-17: Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials, Annual Book of ASTM Standards, 2017.

O.A. Zambrano, J. Valdés, Y. Aguilar, J.J. Coronado, S.A. Rodríguez, and R.E. Logé: Mater. Sci. Eng. A., 2017, vol. 689, pp. 269–85. .

O.A. Zambrano, G. Tressia, and R.M. Souza: Eng. Fail. Anal., 2020, vol. 115, 104621. https://doi.org/10.1016/j.engfailanal.2020.104621.

Y. Ishikawa and Y. Endoh: J. Phys. Soc. Jpn., 1967, vol. 23, pp. 205–13. https://doi.org/10.1143/JPSJ.23.205.

G.A. Pérez Alcázar, E.G. Da Silva, and C. Paduani: Hyperfine Interact., 1991, vol. 66, pp. 221–9. https://doi.org/10.1007/BF02395869.

B.K. Vainshtein, V.M. Fridkin, V.L. Indenbom, and P. Paufler: Modern Crystallography 2, vol. 2, 3rd edn., 2000, pp. 1–122.

Y. Sutou, N. Kamiya, R. Umino, L. Ohnuma, and K. Ishida: ISIJ Int., 2010, vol. 50, pp. 893–9. https://doi.org/10.2355/isijinternational.50.893.

O.A. Zambrano, Y. Aguilar, J. Valdés, S.A. Rodríguez, and J.J. Coronado: Wear., 2016, vol. 348–349, pp. 61–8. https://doi.org/10.1016/j.wear.2015.11.019.

Acknowledgments

The authors acknowledge the support of Minciencias (Colombian Agency), Organización Hercules, and the Universidad del Valle under Project No. 1106-715-51419. The authors also thank project CI 71008 of the Universidad del Valle. Roland Logé acknowledges the generous support of the PX Group to the Thermomechanical Metallurgy Laboratory at EPFL. Oscar Zambrano would like to acknowledge the National Research Council Canada for support. The views and conclusions contained herein are those of the authors and should not be interpreted as necessarily representing the official policies or endorsements, either expressed or implied.

Data Availability

The raw/processed data required to reproduce these findings can be shared upon request.

Conflict of interest

The authors declare that they have no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 13, 2021; accepted August 1, 2021.

Rights and permissions

About this article

Cite this article

Durán, J.F., Pérez, G.A., Rodríguez, J.S. et al. Microstructural Evolution Study of Fe–Mn–Al–C Steels Through Variable Thermomechanical Treatments. Metall Mater Trans A 52, 4785–4799 (2021). https://doi.org/10.1007/s11661-021-06424-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06424-0