Abstract

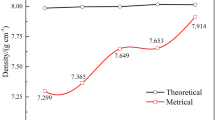

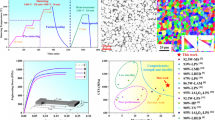

Powder metallurgy (P/M) has been widely used in automobile, home appliances, and electronic devices, but its uses are very limited due to the low relative density of 85 to 95 pct. The Fe–Ni–B–C alloy system can mitigate the aforementioned issues by the liquid phase sintering, which results in a nearly full densification. However, the boron-containing alloys produced the brittle eutectic phases [Fe3(C, B) and Fe2B] along the grain boundaries, which are detrimental to the mechanical properties. The main objective of this study is to improve the ductility of boron-containing alloys through the microstructure modification. For this, the volume fraction of solidified phase was optimized by controlling the composition, and the coarsening of solidified α-Fe particles into the pearlite matrix was induced by a post annealing, which reduces the continuous network of eutectic phases and increased the grain continuity. In addition, the effect of microstructure modification on the mechanical properties of Fe–B–C and Fe–Ni–B–C alloys was comparatively investigated. As a result of microstructure modification, the post-annealed Fe–1Ni–0.4B–0.8C alloy exhibited a high elongation to failure of 5.2 pct.

Similar content being viewed by others

References

K.S. Narasimhan: Mater. Chem. Phys., 2001, vol. 67, pp. 56–65. .

A. Hadrboletz and B. Weiss: Int. Mater. Rev., 1997, vol. 42, pp. 1–44. .

B.A. James: Powder Metall., 1985, vol. 28, pp. 121–30. .

R.M. German, P. Suri, and S.J. Park: J. Mater. Sci., 2009, vol. 44, pp. 1–39. .

J. Liu, A. Upadhyaya, and R.M. German: Metall. Mater. Trans. A., 1999, vol. 30A, pp. 2209–20. .

H. Borgström and L. Nyborg: J. Iron Steel Res. Int., 2007, vol. 14, pp. 70–6. .

H. Preusse and J.D. Bolton: Powder Metall., 1999, vol. 42, pp. 51–62. .

S.J. Jamil and G.A. Chadwick: Powder Metall., 1985, vol. 28, pp. 65–71. .

M. Marucci, A. Lawley, R. Causton, and S. Saritas: Proc. Powder Metall. Congr. Exhib., Orlando, Florida, USA, 2002, pp. 53–62.

Y.C. Peng, H.J. Jin, J.H. Liu, and G.L. Li: Mater. Sci. Eng. A., 2011, vol. 529, pp. 321–5. .

H.O. Gulsoy, M.K. Bilici, Y. Bozkurt, and S. Salman: Mater. Des., 2007, vol. 28, pp. 2255–9. .

J. Lentz, A. Röttger, and W. Theisen: Acta Mater., 2015, vol. 99, pp. 119–29. .

C. Yang, F. Liu, G. Yang, Y. Chen, N. Liu, and Y. Zhou: J. Alloys Compd., 2007, vol. 441, pp. 101–6. .

Y. Tomita: Int. Mater. Rev., 2000, vol. 45, pp. 27–37. .

H. Fayazfar, M. Salarian, A. Rogalsky, D. Sarker, P. Russo, V. Paserin, and E. Toyserkani: Mater. Des., 2018, vol. 144, pp. 98–128. .

Z. Xiu, A. Salwen, X. Qin, F. He, and X. Sun: Powder Metall., 2003, vol. 46, pp. 171–4. .

M.W. Wu, Y.C. Fan, H.Y. Huang, and W.Z. Cai: Metall. Mater. Trans. A., 2015, vol. 46A, pp. 5285–95. .

T.B. Sercombe: Mater. Sci. Eng. A., 2003, vol. 344, pp. 312–7. .

M. Sarasola, T. Gómez-Acebo, and F. Castro: Acta Mater., 2004, vol. 52, pp. 4614–22. .

R. Annamalai, A. Upadhyaya, and D. Agrawal: Bull. Mater. Sci., 2013, vol. 36, pp. 447–56. .

F.L. Serafini, M. Peruzzo, I. Krindges, M.F.C. Ordoñez, D. Rodregues, R.M. Souza, and M.C.M. Farias: Mater. Charact., 2019, vol. 152, pp. 253–64. .

S. Ma, J. Xing, S. Guo, Y. Bai, H. Fu, P. Lyu, Z. Huang, and W. Chen: Mater. Chem. Phys., 2017, vol. 199, pp. 356–69. .

M. Selecka, A. Salak, L. Parilak, and H. Danninger: Proc. 2000 PM World Congr., Kyoto, Japan, JPMA ed., 2000, Part 1, pp. 16–20.

T. Ogawa and T. Koseki: Weld. Res. Suppl., 1989, vol. 68, pp. 181–91. .

M. Selecká, A. Šalak, and H. Danninger: J. Mater. Process. Technol., 2003, vol. 143, pp. 910–5. .

X. Wei, Z. Chen, J. Zhong, L. Wang, W. Yang, and Y. Wang: Comput. Mater. Sci., 2018, vol. 147, pp. 322–30. .

M. Sarasola, S. Sainz, and F. Castro: Euro. PM Conf. Proc., 2005, vol. 1, pp. 349–56. .

C. Tojal, T. Gómez-Acebo, and F. Castro: Mater. Sci. Forum., 2007, vol. 534–536, pp. 661–4. .

M. Skałoń, M. Hebda, K. Sulikowska, and J. Kazior: Mater. Des., 2016, vol. 108, pp. 462–9. .

M.V. Sundaram, K.B. Surreddi, E. Hryha, A. Veiga, S. Berg, F. Castro, and L. Nyborg: Metall. Mater. Trans. A., 2018, vol. 49A, pp. 255–63. .

M.W. Wu, W.Z. Cai, Z. Lin, and S. Chang: Mater. Des., 2017, vol. 133, pp. 536–48. .

M.W. Wu and W.Z. Cai: Mater. Charact., 2016, vol. 113, pp. 90–7. .

S. Egashira, T. Sekiya, T. Ueno, and M. Fujii: Jpn Soc. Mech. Eng., 2019, vol. 6, pp. 1–11. .

B.H. Rabin and R.M. German: Metall. Trans. A., 1988, vol. 19, pp. 1523–32. .

H.I. Bakan, D. Heaney, and R.M. German: Powder Metall., 2001, vol. 44, pp. 235–42. .

Z. Liu, X. Chen, Y. Li, and K. Hu: J. Iron Steel Res. Int., 2009, vol. 16, pp. 37–42. .

H. Fu, Q. Xiao, J. Kuang, and J. Xing: Mater. Sci. Eng. A., 2017, vol. 466, pp. 160–5. .

F. Li and Z. Li: J. Alloys Compd., 2014, vol. 587, pp. 267–72. .

J.O. Andersson, T. Helander, L. Hoglund, P. Shi, and B. Sundman: Calphad., 2002, vol. 26, pp. 273–312. .

Y. Yi, Q. Li, J. Xing, H. Fu, D. Yi, Y. Liu, and B. Zheng: Mater. Sci. Eng. A., 2019, vol. 754, pp. 129–39. .

N. Tosangthum, P. Kunnam, M. Morakotjinda, W. Koetniyom, R. Krataitong, P. Wila, and R. Tongsri: Key Eng. Mater., 2019, vol. 798, pp. 9–16. .

J. Karwan-Baczewska: Arch. Metall. Mater., 2011, vol. 56, pp. 789–96. .

W. Koetniyom, P. Chantawet, N. Tosangthum, M. Morakotjinda, T. Yotkaew, P. Wila, and R. Tongsri: J. Met. Mater. Miner., 2019, vol. 29, pp. 22–30. .

R.M. German and K.A. D’Angelo: Int. Met. Rev., 1984, vol. 29, pp. 229–72. .

P. Sang, H. Fu, Y. Qu, C. Wang, and Y. Lei: Werkstofftech., 2015, vol. 46, pp. 962–9. .

X. Ren, H. Fu, J. Xing, Y. Yang, and S. Tang: J. Mater. Res., 2017, vol. 32, pp. 3078–88. .

Y. Penghui, F. Hanguang, L. Guolu, L. Jinhai, and Z. Xuebo: Mater. Des., 2020, vol. 186, p. 108363. .

M.A. Taha, A.F. Yousef, K.A. Gany, and H.A. Sabour: Mat.-wiss. u Werkstofftech., 2012, vol. 43, pp. 913–23. .

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) Grant funded by the Korea government (MSIT) (No. NRF-2020R1A5A6017701).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 22, 2020; accepted July 8, 2021.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

You, J., Kim, H.G., Lee, J. et al. Microstructure Modification of Liquid Phase Sintered Fe–Ni–B–C Alloys for Improved Mechanical Properties. Metall Mater Trans A 52, 4395–4401 (2021). https://doi.org/10.1007/s11661-021-06392-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06392-5