Abstract

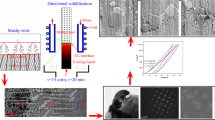

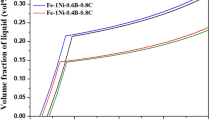

In this work, the effects of chromium addition on the morphology and mechanical properties of Fe2B in Fe-3.0B alloy have been systematically investigated by a combination of experimental observations and the first-principles calculations. The results indicate that, with chromium addition in Fe-3.0B alloy ranging from 0 to 2.5 wt%, the average grain size of the boride firstly decreases and then increases slightly, mainly attributed to the volume fraction of coarse block boride. The nanoindentation hardness H of the boride remains almost constant while the elastic modulus E r firstly drops and then rises. Accordingly, the H/E r of the boride achieves a peak value at the chromium addition of 2.0 wt%, where the highest toughness is obtained. High-resolution transmission electron microscopy (HRTEM) observation demonstrates that the lattice of borides evolves from tetragonal to orthorhombic ((Fe, Cr)2B) after chromium addition, in good accordance with the calculation results. During the lattice evolution, a shrinkage of B–B bond along [002] direction is simultaneously revealed. The inherently weak B–B bond can be strengthened, which improves fracture toughness of Fe2B.

Similar content being viewed by others

References

Çetinkaya C (2006) Mater Des 27:437–445. https://doi.org/10.1016/j.matdes.2004.11.021

Chen KM, Zhou Y, Li XX, Zhang QY, Wang L, Wang SQ (2015) Mater Des 65:65–78. https://doi.org/10.1016/j.matdes.2014.09.016

Yasir M, Zhang C, Wang W, Xu P, Liu L (2015) Mater Des 88:207–213. https://doi.org/10.1016/j.matdes.2015.08.142

Zhou Y, Zhang QY, Liu JQ, Cui XH, Mo JG, Wang SQ (2015) Wear 344–345:9–21. https://doi.org/10.1016/j.wear.2015.10.015

Xu X, van der Zwaag S, Xu W (2016) Wear 348–349:80–88. https://doi.org/10.1016/j.wear.2015.11.017

Zambrano OA, Aguilar Y, Valdés J, Rodríguez SA, Coronado JJ (2016) Wear 348–349:61–68. https://doi.org/10.1016/j.wear.2015.11.019

Zhang N, Zhang J, Lu L, Zhang M, Zeng D, Song Q (2016) Mater Des 89:815–822. https://doi.org/10.1016/j.matdes.2015.10.037

ASM International Alloy Phase Diagram and the Handbook Committees (1992) ASM handbook, volume 3: alloy phase diagrams. ASM International, Materials Park, OH

Jian Y, Huang Z, Xing J, Guo X, Jiang K (2017) J Mater Res. https://doi.org/10.1557/jmr.2017.41

Jian Y, Huang Z, Xing J, Li J (2017) Wear 378–379:165–173. https://doi.org/10.1016/j.wear.2017.02.042

Jian Y, Huang Z, Xing J, Guo X, Wang Y, Lv Z (2016) Tribol Int 103:243–251. https://doi.org/10.1016/j.triboint.2016.07.008

Jian Y, Huang Z, Xing J et al (2016) Wear 362–363:68–77. https://doi.org/10.1016/j.wear.2016.04.029

Jian Y, Huang Z, Xing J, Wang B (2015) Mater Charact 110:138–144. https://doi.org/10.1016/j.matchar.2015.10.017

Lv Z, Fu H, Xing J, Huang Z, Ma S, Hu Y (2016) Corros Sci 108:185–193. https://doi.org/10.1016/j.corsci.2016.03.002

Lv Z, Fu H, Xing J, Ma S, Hu Y (2016) J Alloy Compd 662:54–62. https://doi.org/10.1016/j.jallcom.2015.11.171

Wang Y, Xing J, Ma S et al (2015) Corros Sci 98:240–248. https://doi.org/10.1016/j.corsci.2015.05.039

Ma S, Xing J, He Y, Fu H, Li Y, Liu G (2016) Acta Mater 115:392–402. https://doi.org/10.1016/j.actamat.2016.06.016

Zhang J, Gao Y, Xing J, Ma S, Yi D, Yan J (2011) Tribol Lett 44:31–39. https://doi.org/10.1007/s11249-011-9823-5

Yi D, Xing J, Ma S et al (2011) Tribol Lett 45:427–435. https://doi.org/10.1007/s11249-011-9900-9

Lentz J, Röttger A, Theisen W (2015) Acta Mater 99:119–129

Musen L, Shaoli F, Wandong X, Ruihuang ZRY (1995) Acta Metall Sin 31:201–207

Frutos E, González-Carrasco JL (2013) Acta Mater 61:1886–1894. https://doi.org/10.1016/j.actamat.2012.12.009

Jian S-R, Chen G-J, Hsu W-M (2013) Materials 6:4505–4513. https://doi.org/10.3390/ma6104505

Zhang T, Feng Y, Yang R, Jiang P (2010) Scripta Mater 62:199–201. https://doi.org/10.1016/j.scriptamat.2009.10.025

Oliver WC, Pharr GM (1992) J Mater Res 7:1564–1583

Li X, Bhushan B (2002) Mater Charact 48:11–36

Xiao B, Feng J, Zhou CT et al (2010) Physica B 405:1274–1278. https://doi.org/10.1016/j.physb.2009.11.064

Monkhorst HJ, Pack JD (1976) Phys Rev B 13:5188–5192

Xiao B, Xing JD, Ding SF, Su W (2008) Physica B 403:1723–1730. https://doi.org/10.1016/j.physb.2007.10.014

W Lu, L Li, L Huang (2002) China Machine Press, Beijing

Scandian C, Boher C, de Mello JDB, Rézaï-Aria F (2009) Wear 267:401–408. https://doi.org/10.1016/j.wear.2008.12.095

H Chen, J Xing, W Li (2006) China Machine Press, Beijing

Q Zhou (1986) Xi’an Jiaotong University Press, Xi’an: 18

BB Mandelbrot, DE Passoja, AJ Paullay (1984)

Radulovic M, Fiset M, Peev K, Tomovic M (1994) Journal of Materials Science 29:5085–5094. https://doi.org/10.1023/B:JMSC.0000007730.00517.65

Zhou J, WANG Y, LIU Z (2000) J East China Univ Sci Technol 26:188–190

Anstis PCGR, Lawn BR, Marshall DB (1981) J Am Ceram Soc 64:533–538

Mukhopadhyay NK, Belger A, Paufler P, Kim DH (2007) Mater Sci Eng A 449–451:954–957. https://doi.org/10.1016/j.msea.2006.02.258

Ozmetin AE, Sahin O, Ongun E, Kuru M (2015) J Alloy Compd 619:262–266. https://doi.org/10.1016/j.jallcom.2014.09.015

Vincent S, Murty BS, Kramer MJ, Bhatt J (2015) Mater Des 65:98–103. https://doi.org/10.1016/j.matdes.2014.09.017

Havinga E, Damsma H, Hokkeling P (1972) J Less Common Metals 27:169–186

Acknowledgements

Yongxin Jian thanks to Zhifu Huang, Jiandong Xing and Yimin Gao for their good advice. This work was supported by the National Natural Science Foundations of China (Grant No: 51371138 and 51571159), the Science and Technology Project of Guangdong Province in China (2015B090926009) and the Science and Technology Project of Guangzhou City in China (201604046009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work. We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Rights and permissions

About this article

Cite this article

Jian, Y., Huang, Z., Xing, J. et al. Effects of chromium on the morphology and mechanical properties of Fe2B intermetallic in Fe-3.0B alloy. J Mater Sci 53, 5329–5338 (2018). https://doi.org/10.1007/s10853-017-1936-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1936-2