Abstract

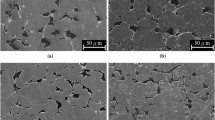

Liquid phase sintering is an effective method to improve the densification of powder metallurgy materials. Boron is an excellent alloying element for liquid phase sintering of Fe-based materials. However, the roles of chromium and carbon, and particularly that of the former, on liquid phase sintering are still undetermined. This study demonstrated the effects of chromium and carbon on the microstructure, elemental distribution, boride structure, liquid formation, and densification of Fe-B-Cr and Fe-B-Cr-C steels during liquid phase sintering. The results showed that steels with 0.5 wt pct C densify faster than those without 0.5 wt pct C. Moreover, although only one liquid phase forms in Fe-B-Cr steel, adding 0.5 wt pct C reduces the formation temperature of the liquid phase by about 50 K (°C) and facilitates the formation of an additional liquid, resulting in better densification at 1473 K (1200 °C). In both Fe-B-Cr and Fe-B-Cr-C steels, increasing the chromium content from 1.5 to 3 wt pct raises the temperature of liquid formation by about 10 K (°C). Thermodynamic simulations and experimental results demonstrated that carbon atoms dissolved in austenite facilitate the eutectic reaction and reduce the formation temperature of the liquid phase. In contrast, both chromium and molybdenum atoms dissolved in austenite delay the eutectic reaction. Furthermore, the 3Cr-0.5Mo additive in the Fe-0.4B steel does not change the typical boride structure of M2B. With the addition of 0.5 wt pct C, the crystal structure is completely transformed from M2B boride to M3(B,C) boro-carbide.

Similar content being viewed by others

References

J. M. Torralba, A. Navarro, and M. Campos: Mater. Sci. Eng. A, 2013, Vol. 573, pp. 253-56.

H. Danninger, C. Xu, G. Khatibi, B. Weiss, and B. Lindqvist: Powder Metall., 2012, Vol. 55, pp. 378-87.

J. Desbiens, E. Robert-Perron, C. Blais, and F. Chagnon: Mater. Sci. Eng. A, 2012, Vol. 546, pp. 218-22.

M. Campos, J. Sicre-Artalejo, J. J. Munoz, and J. M. Torralba: Metall. Mater. Trans. A, 2010, Vol. 41A, pp. 1847-54.

F. Bernier, P. Plamondon, J. P. Baïlon, and G. L’Espèrance: Powder Metall., 2011, Vol. 54, pp. 559-65.

M. Gauthier, S. Metcalfe, S. Pelletier, and T. F. Stephenson: Powder Metall., 2011, Vol. 54, pp. 628-35.

M. W. Wu, K. S. Hwang, and H. S. Huang: Metall. Mater. Trans. A, 2007, Vol. 38A, pp. 1598-1607.

M. W. Wu, L. C. Tsao, G. J. Shu, and B. H. Lin: Mater. Sci. Eng. A, 2012, Vol. 538, pp. 135-44.

M. W. Wu, G. J. Shu, S. Y. Chang, and B. H. Lin: Metall. Mater. Trans. A, 2014, Vol. 45A, pp. 3866-75.

R. M. German, K. S. Hwang, and D. S. Madan: Powder Metall. Int., 1987, Vol. 19, pp. 15-18.

E. Dudrová, M. Selecká, R. Bureś, and M. Kabátová: ISIJ Int., 1997, Vol. 37, pp. 59-64.

M. Selecká, A. Šalak, and H. Danninger: J. Mater. Process. Technol., 2003, Vol. 143-144, pp. 910-15.

M. Sarasola, T. G. Acebo, and F. Castro: Acta Mater., 2004, Vol. 52, pp. 4615-22.

A. Molinari, T. Pieczonka, J. Kazior, S. Gialanella, and G. Straffelini: Metall. Mater. Trans. A, 2000, Vol. 31A, pp. 1497-1506.

M. Momeni, C. Gierl, H. Danninger, and A. Avakemian: Powder Metall., 2012, Vol. 55, pp. 54-64.

J. Liu, A. Cardamone, T. Potter, R. M. German, and F. J. Semel: Powder Metall., 2000, Vol. 43, pp. 57-61.

Z. Xiu, A. Salwen, X. Qin, F. He, and X. Sun: Powder Metall., 2003, Vol. 46, pp. 171-74.

M. W. Wu, Metall. Mater. Trans. A, 2015, Vol. 46A, pp. 467–75.

L. Lozada and F. Castro: Adv. Powder Metall. Part. Mater., 2011, Part 7, pp. 78–88.

C. Menapace, A. Molinari, J. Kazior, and T. Pieczonka: Powder Metall., 2007, Vol. 50, pp. 326-35.

H. Ö. Gulsoy: Scripta Mater., 2005, Vol. 52, pp. 187-92.

T.B. Sercombe: Mater. Sci. Eng. A, 2003, Vol. 344, pp. 312-17.

T. B. Sercombe and G. B. Schaffer: Mater. Sci. Eng. A, 2010, Vol. 528, pp. 751-55.

A. Röttger, S. Weber, and W. Theisen: Mater. Sci. Eng. A, 2012, Vol. 532, pp. 511-21.

G. Cui and Z. Kou: J. Alloys Compd., 2014, Vol. 586, pp. 699-702.

R. L. Lawcock and T. J. Davies: Powder Metall., 1990, Vol. 33, pp. 147-50.

C. T. Huang and K. S. Hwang: Powder Metall., 1996, Vol. 39, pp. 119-23.

A. Molinari, G. Straffelini, V. Fontanari, and R. Canteri: Powder Metall., 1992, Vol. 35, pp. 285-91.

G. Straffelini, V. Fontanari, A. Molinari, and B. Tesi: Powder Metall., 1993, Vol. 36, pp. 135-41.

S. Bueno, S. Saccarola, A. Karuppannagounder, A. Veiga, S. Sainz and F. Castro: Powder Metall., 2012, Vol. 55, pp. 92-94.

N. Giguère and C. Blais: Metall. Mater. Trans. A, 2013, Vol. 44A, pp. 4774-87.

L. Čiripová, E. Hryha, E. Dudrová, and A. Výrostková: Mater. Des., 2012, Vol. 35, pp. 619-25.

Acknowledgment

The authors thank the Ministry of Science and Technology of the Republic of China for supports under Contract Number MOST 103-2221-E-027-132.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 17, 2014.

Rights and permissions

About this article

Cite this article

Wu, MW., Fan, YC., Huang, HY. et al. Liquid Phase Sintering of Boron-Containing Powder Metallurgy Steel with Chromium and Carbon. Metall Mater Trans A 46, 5285–5295 (2015). https://doi.org/10.1007/s11661-015-3096-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3096-9