Abstract

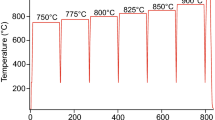

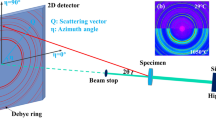

The γ and γ′ lattice parameter evolution of two commercial powder metallurgy (PM) nickel-base superalloys, ME3 and Rene’88DT, during cooling from above the γ′ prime solvus temperature is characterized using in-situ synchrotron X-ray Diffraction (XRD). The peak intensity deconvolution necessary for quantifying misfit between the two phases from XRD is accomplished by combining direct observation of several superlattice peak positions with thermodynamic modeling to quantify the intensity relationship between the overlapping phases. The misfit values obtained from the XRD measurements are compared to Scanning Electron Microscopy (SEM) observations of γ′ precipitate shapes for a subset of the experimental conditions where it can be observed that the exposures that result in cuboidal precipitate shapes are associated with the highest degrees of relative misfit. Time-resolved observations of the on-cooling lattice parameter evolution suggest a potential direct observation of the tertiary γ′ burst events in the two compositions within both the (100) superlattice peak and the (311) fundamental peak. The onset temperatures for the tertiary γ′ burst events for ME3 and Rene’88DT compositions for the cooling rates examined were found to be approximately 925 °C and 815 °C, respectively.

Similar content being viewed by others

References

R.J. Mitchell, M.C Hardy, M. Preuss, S. Tin: Superalloys 2004, Proc. Int. Symp., 10th, pp. 361–70.

[2] A.R.P. Singh, S. Nag, S. Chattopadhyay, Y. Ren, J. Tiley, G.B. Viswanathan, H.L. Fraser, R. Banerjee: Acta Mater., 2013, 61(1), pp. 280-293.

[3] M. Li, J. Coakley, D. Isheim, G. Tian, B. Shallock: J. Alloys Compd., 2018, 732, pp. 765-776.

[4] D.M. Collins, L. Yan, E.A. Marquis, L.D. Connor, J.J. Ciardiello, A.D. Evans, H.J. Stone: Acta Mater., 2013, 61(20), pp. 7791-7804.

[5] X. Fan, A. Zhang, Z. Guo, X. Wang, J. Yang, J. Zou: JOM, 2019, 54(3), pp. 2680-2689

[6] F. Masoumi, D. Shahriari, M. Jahazi, J. Cormier, A. Devaux: Sci. Rep., 2016, 6(1), pp. 1-16.

[7] C. Papadaki, W. Li, A.M. Korsunsky: Mater., 2018, 11(9), pp. 1528.

[8] P.S. Mathur, J.L. Bartos: USAAMRDL-TR-76-30, General Electric Company, Lynn, MA, May 1977.

S.T. Wlodek, M. Kelly, D.A. Alden: Superalloys 1996, Proc. Int. Symp., 8th, pp. 129–36.

T.P. Gabb, A. Garg, D.L. Ellis, and K. O’Conner: NASA Report, TM-2004-213066, 2004.

[11] S.L. Semiatin, F. Zhang, R. Larsen, L.A. Chapman, D.U. Furrer: Integr. Mater. Manuf. Innov., 2016, 5(1), pp. 41-60.

J. Gayda, T.P. Gabb, P.T. Kantzos, D.U. Furrer: NASA Report, TM-2002-211558, 2002.

R.R. Unocic, L. Kovarik, C. Shen, P.M. Sarosi, Y. Wang, J. Li, M.J. Mills: Superalloys 2008, Proc. Int. Symp., 11th, pp. 377-385.

[14] A.J. Goodfellow, L.R. Owen, K.A. Christofidou, J. Kelleher, M.C. Hardy, H.J. Stone: Metals, 2019, 9(6), pp. 700.

[15] M.V. Nathal, R.A. Mackay, R.G. Garlick: Mater. Sci. Eng., 1985, 75(1-2), pp. 195-205.

T.M. Pollock, S. Tin (2006) J. Propul. Power 22(2):361-374.

[17] J.S. Van Sluytman, T.M. Pollock: Acta Mater., 2012, 60(4), pp. 1771-1783.

A. Wisniewski, J. Beddoes (2009) Mater. Sci. Eng. A, 510:266-272.

[19] S.L. Semiatin, S.L. Kim, F. Zhang, J.S. Tiley: Metall. Trans. A, 2015, 46(4), pp. 1715-1730.

J. Mao, K. Chang, W. Yang, K. Ray, S. Vaze, D.U. Furrer: Metall. Trans. A, 2001, pp. 2441–52.

T.P. Gabb, D.G. Backman, D.Y. Wei, D.P. Mourer, D. Furrer, A. Garg, D.L. Ellis: Superalloys 2000, Proc. Int. Symp., 9th, pp. 405–14.

[22] R.A. Ricks, A.J. Porter, R.C. Ecob: Acta Metall., 1983, 31(1), pp. 43-53.

[23] Y.S. Yoo, D.Y. Yoon, A.M. Henry: Metals and Materials, 1995, 1(1), pp. 47-61.

A.G. Khachaturyan: Theory of Structural Transformations in Solids, Courier Corporation, Chelmsford, 2013.

[25] H.J. Stone, T.M. Holden, R.C. Reed: Acta Mater., 1999, 47(17), pp. 4435-4448.

[26] R.Y. Zhang, H.L. Qin, Z.N. Bi, J. Li, S. Paul, T.L. Lee: Metall. Trans. A, 2020, 51(4), pp. 1860-1873.

[27] D. M. Collins, D.J. Crudden, E. Alabort, T. Connolley, R.C. Reed: Acta Mater., 2015, 94, pp. 244-256.

[28] M.C. Hardy, M. Detrois, E.T. McDevitt, C. Argyrakis, V. Saraf, P.D. Jablonski, S. Tin: Metall. Trans. A, 2020, 51(6), pp. 2626-2650.

D.P. Mourer, K.R. Bain, P.L. Reynolds, J.J. Shirra, and T.P. Gabb: European Patent Application EP1 195 446 A1, 2000.

T.P. Gabb, J. Gayda, D.F. Johnson, R.A. MacKay, R.B. Rogers, C.K. Sudbrack, A. Garg, I.E. Locci, S.L. Semiatin: NASA Report, 2016-218936, 2016.

J. Cormier: Superalloys 2016, Proc. Int. Symp., 13th, pp. 383–94.

A.P. Hammersley: ESRF Internal Report, ESRF97HA02T, 1997.

[33] A. P. Hammersley, S. O. Svensson, M. Hanfland, A. N. Fitch, and D. Häusermann: High Pressure Res., 1996, 14, pp. 235-248.

[34] B.E. Warren: X-Ray Diffraction. Addison-Wesley, Massachusetts, 1969.

[35] B.D. Cullity, S.R. Stock: Elements of X-ray Diffraction, 3rd ed., Prentice Hall, New Jersey, 2001, pp. 348-355.

[36] J.O. Andersson, T. Helander, L. Höglund, P.F. Shi, B. Sundman: Calphad, 2002, 26, pp. 273-312.

T.P. Gabb, A. Garg, D.L. Ellis: NASA Report, TM-2004-213123, 2004.

G. Esteves, K. Ramos, C.M. Fancher, J.L. Jones: LIPRAS: Line-Profile Analysis Software, 2017. https://doi.org/10.13140/rg.2.2.29970.25282/3.

D.A. Porter, K.E. Easterling, M.Y. Sherif: Phase Transformations in Metals and Alloys. 3rd ed., Taylor & Francis Group LLC, 2009.

C. Shen, Modeling Creep-Fatigue-Environment Interactions in Steam Turbine Rotor Materials for Advanced Ultra-supercritical Coal Power Plants (2014). https://www.osti.gov/servlets/purl/1134364.

T.P. Gabb, J. Gayda, J. Telesman, P.T. Kantzos: NASA Report, 20050186902, 2005.

S. Huang, K. An, Y. Gao, A. Suzuki (2018) Metall. Mater. Trans. A, 49(3):740–751.

G.B. McBride (2005) Using Statistical Methods for Water Quality Management. Wiley, New York, pp. 305-313.

[44] J. Mao, K.M. Chang, W. Yang, D.U. Furrer, K. Ray, V.P. Vaze: Materials Science & Engineering A, 2002, 332(1-2), pp. 318-329.

[45] D.M. Collins, N. D’Souza, C. Panwisawas, C. Papadaki, G.D. West, P. Kontis: Acta Mater., 2020, 200, pp.959-70.

[46] S.L. Semiatin, N.C. Levkulich, J.S. Tiley: Metall. Trans. A, 2019, 50(11), 5281-5296.

[47] J. Tiley, R. Srinivasan, R. Banerjee, G.B. Viswanathan, B. Toby, H.L. Fraser: Mater. Sci. Technol., 2009, 25(11), 1369-1374.

[48] S.L. Semiatin, D.W. Mahaffey, N.C. Levkulich, O.N. Senkov, J.S. Tiley: Metall. Trans. A, 2018, 49(12), pp. 6265-6276.

Y.U. Wang, Y.M. Jin, A.G. Khachaturyan (2002) J. Appl. Phys. 92(3):1351-1360.

M. Akhlaghi, T. Steiner, S.R. Meka, E.J. Mittemeijer (2016) J. Appl. Crystallogr. 49(1):69

Acknowledgments

The authors acknowledge GE Aviation for its financial support on this program. NJK acknowledges Jeffrey Williams for his editorial and technical support and Daryl Werner for his support in fabricating the furnace equipment used for this program. NJK and YG acknowledge Chen Shen for his thermodynamic modeling support. This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 11, 2020; accepted April 8, 2021.

Rights and permissions

About this article

Cite this article

Krutz, N.J., Gao, Y., Ren, Y. et al. In-Situ γ-γ′ Lattice Parameter Evolution and Tertiary Burst Phenomena During Controlled Cooling of Commercial PM Nickel-Base Superalloys. Metall Mater Trans A 52, 2973–2991 (2021). https://doi.org/10.1007/s11661-021-06292-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06292-8