Abstract

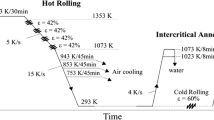

In the present work, a modified 9Cr-1Mo steel is subjected to normalizing and tempering treatment with or without an intermediate rolling, which was carried out at 1050 °C in austenitic phase and 550 °C in metastable austenitic phase. The tempering was carried out at 700 °C and 750 °C to improve the strength by precipitation hardening and refining the microstructure. The ductile to brittle-transition temperature (DBTT) and tensile properties have been evaluated at 20 °C, 550 °C and 650 °C for the material subjected to various thermomechanical treatments. Rolling performed in austenitic phase showed improvement in the upper shelf energy and reduction in the DBTT compared with the material rolled in metastable austenitic phase. Rolling in metastable austenitic phase improved the yield strength at elevated temperature (39 pct at 20 °C, 31 pct at 550 °C and 91 pct at 650 °C) and was accompanied by a reduction in ductility (21 pct at 20 °C, 32 pct at 550 °C and 35 pct at 650 °C) compared with the as-received condition. The influence of grain size, low angle boundaries and precipitates on DBTT and high temperature strength has been studied using EBSD and TEM analyses. An increase in high temperature strength is found to increase with the area fraction of fine M23C6/MX precipitates, whereas low angle boundaries and effective grain size influenced the DBTT behavior. The combined effect of precipitation strengthening and strain hardening leads to improvement in the high temperature mechanical strength while maintaining adequate toughness. The effect of aging (for 72 hours at 650 °C) on heat-treated and -rolled samples showed a small decrease in yield strength at 20 °C. A decreasing trend of fracture toughness is observed with the increase in yield strength.

Similar content being viewed by others

References

RL Klueh, AT Nelson: J. Nucl. Mater., 2007, vol. 371, pp. 37–52.

Guidelines for application of the Master Curve approach to reactor pressure vessel integrity in nuclear power plants, IAEA, 2005.

3. S. Hollner, B. Fournier, J. Le Pendu, T. Cozzika, I. Tournié, J.C. Brachet and A. Pineau: J. Nucl. Mater., 2010, vol. 405, pp. 101–108.

4. J.H. Kim, J.H. Baek, S.H. Kim, C.B. Lee, K.S. Na and S.J. Kim: Ann. Nucl. Energy, 2011, vol. 38, pp. 2397–2403.

5. R.L. Klueh and J.M. Vitek: J. Nucl. Mater., 1991, vol. 182, pp. 230–239.

6. R.L. Klueh and J.M. Vitek: J. Nucl. Mater., 1985, vol. 132, pp. 27–31.

7. R.L. Klueh and J.M. Vitek: J. Nucl. Mater., 1985, vol. 137, pp. 44–50.

8. R.L. Klueh and J.M. Vitek: J. Nucl. Mater., 1989, vol. 161, pp. 13–23.

W.L. Hu, D.S. Gelles, F.A. Garner, C.H. Henager Jr. and N. Igata (1987) ASTM STP 956. American Society for Testing and Materials, Philadelphia.

10. R.L. Klueh, D.J. Alexander, R.E. Stoller, A.S. Kumar and D.S. Gelles, ASTM STP 1125, American Society for Testing and Materials, Philadelphia, 1992.

R.L. Klueh, D.J. Alexander, Arvind S. Kumar, David S. Gelles and andy K. Nanstad (1994) ASTM STP 1175. American Society for Testing and Materials, Philadelphia

12. C. Wassilew and K. Ehrlich: J. Nucl. Mater., 1992, vol. 194, pp. 850–854.

T. Karthikeyan, V. Thomaspaul, S. Saroja, A. Moitra, G. Sasikala and M. Vijayalakshmi: J. Nucl. Mater., 2011, vol. 419, pp. 256–262.

14. P. Yan, Z. Liu, H. Bao, Y. Weng and W. Liu: Mater. Des., 2014, vol. 54, pp. 874–879.

15. P.K. Parida, A. Dasgupta and S. Saibaba: J. Nucl. Mater., 2013, vol. 432, pp. 450–454.

16. C. Pandey, A. Giri and M.M. Mahapatra: Mater. Sci. Eng. A., 2016, vol. 657, pp. 173–184.

17. X. Gong, P. Marmy, L. Qin, B. Verlinden, M. Wevers and M. Seefeldt: J. Nucl. Mater., 2016, vol. 468, pp. 289–298.

18. Z.B. Zhang, O. V Mishin, N.R. Tao and W. Pantleon: J. Nucl. Mater., 2015, vol. 458, pp. 64–69.

19. S. Goyal and K. Laha: Mater. Sci. Eng. A., 2014, vol. 615, pp. 348–360.

Standard Test Methods for Tension Testing of Metallic Materials, ASTM E8/E8M-13a (2013).

Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials, ASTM E21-09 (2009).

Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, ASTM E23-12c (2013).

Standard Test Method for Measurement of Fracture Toughness, ASTM E1820-13 (2014).

24. A. Chatterjee, D. Chakrabarti, A. Moitra, R. Mitra and A.K. Bhaduri: Mater. Sci. Eng. A., 2014, vol. 618, pp. 219–231.

R.L. Klueh and D.R. Harries: ASTM International, June 2001.

26. A. Chatterjee, D. Chakrabarti, A. Moitra, R. Mitra and A.K. Bhaduri:. Mater. Sci. Eng. A, 2015, vol. 630, pp. 58–70.

27. J.I. Langford and A.J.C. Wilson: J. Appl. Crystallogr., 1978, vol. 11, pp. 102–113.

28. A. Sarkar and K.L. Murty: J. Nucl. Mater., 2015, vol. 456, pp. 287–291.

29. M. Gwoździk and Z. Nitkiewicz: Arch. Metall. Mater., 2013, vol. 58, pp. 31–34.

30. D. Fuloria, N. Kumar, S. Goel, R. Jayaganthan, S. Jha and D. Srivastava: Mater. Des., 2016, vol. 103, pp. 40–51.

31. B.N. Mordyuk, Y. V. Milman, M.O. Iefimov, G.I. Prokopenko, V. V. Silberschmidt, M.I. Danylenko and A. V. Kotko: Surf. Coatings Technol., 2008, vol. 202, pp. 4875–4883.

Standard practise for conducting surveillance test for lightwater cooled nuclear power reactor vessels, ASTM E185-82e2, 1982.

Guide on methods for assessing the acceptability of flaws in metallic structure, BS7910:1999, London, 1999.

34. A. Das, S.K. Das and S. Tarafder: Metall. Mater. Trans. A, 2009, vol. 40, pp. 3138–3146.

35. D. Bhattacharjee and C.L. Davis: Scr. Mater., 2003, vol. 47, pp. 825–831.

36. S.S. Samant, I. V Singh and R.N. Singh: J. Mater. Eng. Perform., 2018, vol. 27, pp. 5898–5912.

37. S.S. Samant, I. V Singh and R.N. Singh: Mater. Sci. Eng. A., 2018, vol. 738, pp. 135–152.

38. C. Wang, M. Wang, J. Shi, W. Hui and H. Dong: Scr. Mater., 2008, vol. 58, pp. 492–495.

39. J.F. Knott, Fundamentals of Fracture Mechanics, Butterworths, London, 1973.

40. A. Ghosh, S. Sahoo, M. Ghosh, R.N. Ghosh and D. Chakrabarti: Mater. Sci. Eng. A., 2014, vol. 613, pp. 37–47.

Acknowledgments

The authors are thankful to Bhabha Atomic Research Center (BARC), Mumbai, India, for providing the material and the Indian Institute of Technology, Roorkee, for the research facilities. This study did not receive any funding from any other source.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 26, 2019.

Rights and permissions

About this article

Cite this article

Samant, S.S., Singh, I.V. & Singh, R.N. Effect of Thermo-mechanical Treatment on High Temperature Tensile Properties and Ductile–Brittle Transition Behavior of Modified 9Cr-1Mo Steel. Metall Mater Trans A 51, 3869–3885 (2020). https://doi.org/10.1007/s11661-020-05846-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05846-6