Abstract

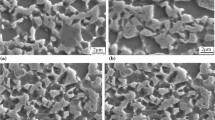

C–Mn steels prepared by annealing at 800°C for 120 s and overaging at 250–400°C were subjected to pre-straining (2%) and baking treatments (170°C for 20 min) to measure their bake-hardening (BH2) values. The effects of overaging temperature on the microstructure, mechanical properties, and BH2 behavior of 600 MPa cold-rolled dual-phase (DP) steel were investigated by optical microscopy, scanning electron microscopy, and tensile tests. The results indicated that the martensite morphology exhibited less variation when the DP steel was overaged at 250–350°C. However, when the DP steel was overaged at 400°C, numerous non-martensite and carbide particles formed and yield-point elongation was observed in the tensile curve. When the overaging temperature was increased from 250 to 400°C, the yield strength increased from 272 to 317 MPa, the tensile strength decreased from 643 to 574 MPa, and the elongation increased from 27.8% to 30.6%. Furthermore, with an increase in overaging temperature from 250 to 400°C, the BH2 value initially increases and then decreases. The maximum BH2 value of 83 MPa was observed for the specimen overaged at 350°C.

Similar content being viewed by others

References

Y. L. Kang, Theory and Technology of Processing and Forming for Advanced Automobile Steel Sheets, Metallurgical Industry Press, Beijing, 2009, p. 230.

H. X. Yin, A. M. Zhao, Z. Z. Zhao, X. Li, S. J. Li, H. J. Hu, and W. G. Xia, Influence of original microstructure on the transformation behavior and mechanical properties of ultra-highstrength TRIP-aided steel, Int. J. Miner. Metall. Mater., 22 (2015), No. 3, p. 262.

H. T. Jiang, B. T. Zhuang, X. G. Duan, Y. X. Wu, and Z. X. Cai, Element distribution and diffusion behavior in Q&P steel during partitioning, Int. J. Miner. Metall. Mater., 20 (2013), No. 11, p. 1050.

A. A. Sayed and S. Kheirandish, Affect of the tempering temperature on the microstructure and mechanical properties of dual phase steels, Mater. Sci. Eng. A, 532 (2012), p. 21.

H. Yu and Y. L. Kang, Research on the mechanism of aging of dual phase steel produced by continuous annealing, Adv. Mater. Res., 97-101 (2010), p. 556.

J. Y. Liu, Z. A. Luo, M. H. Shi, and F. X. Zhu, Effects of over-aging temperatures on microstructure and mechanical properties of low cost cold rolled dual phase steels, J. Northeast. Univ. Nat. Sci., 35 (2014), No. 3, p. 375.

Z. Z. Zhao, F. Niu, D. Tang, A. M. Zhao, and G. C. Jin, Microstructure and properties of ultra-high strength cold-rolled dual phase steel, J. Univ. Sci. Technol. Beijing, 32 (2010), No. 10, p. 1287.

C. S. Li, Z. X. Li, Y. M. Cen, B. Ma, and G. Huo, Microstructure and mechanical properties of dual phase strip steel in the overaging process of continuous annealing, Mater. Sci. Eng. A, 627 (2015), p. 281.

C. F. Kuang, J. Li, S. G. Zhang, J. Wang, H. F. Liu, and A. A. Volinsky, Effects of quenching and tempering on the microstructure and bake hardening behavior of ferrite and dual phase steels, Mater. Sci. Eng. A, 613 (2014), p. 178.

J. Y. Ye, Z. Z. Zhao, Z. G. Wang, and A. M. Zhao, Microstructure and mechanical properties of 1000 MPa grade C-Si-Mn-Nb cold-rolled dual-phase steel, Trans. Mater. Heat Treat., 34 (2013), No. 4, p. 138.

M. Calcagnotto, D. Ponge, and D. Raabe, Microstructure control during fabrication of ultrafine grained dual-Phase steel: characterization and effect of intercritical annealing parameters, ISIJ Int., 52 (2012), No. 5, p. 874.

L. Y. Shi, Y. M. Liu, J. H. Huang, S. Q. Zhang, and X. K. Zhao, Growth kinetics of cubic carbide free layers in graded cemented carbides, Int. J. Miner. Metall. Mater., 19 (2012), No. 1, p. 64.

C. F. Kuang, S. G. Zhang, J. Li, J. Wang, and P. Li, Effect of temper rolling on the bake-hardening behavior of low carbon steel, Int. J. Miner. Metall. Mater., 22 (2015), No. 1, p. 32.

T. Waterachoot, A. K. De, S. Vandeputte, and B. C. Cooman, Static strain aging phenomena in cold-rolled dual-phase steel, Metall. Mater. Trans. A, 34 (2003), No. 3, p. 781.

Q. L. Yong, Secondary Phase in Steel Material, Metallurgical Industry Press, Beijing, 2006.

Z. C. Liu, Microstructure and Transformation Theory of Materials, Metallurgical Industry Press, Beijing, 2006.

C. F. Kuang, S. G. Zhang, J. Li, J. Wang, and H. F. Liu, Effect of pre-strain and baking parameters on the microstructure and bake-hardening behavior of dual-phase steel, Int. J. Miner. Metall. Mater., 21 (2014), No. 8, p. 766.

S. Gunduz, Effect of chemical composition, martensite volume fraction and tempering on tensile behaviour of dual phase steels, Mater. Lett., 63 (2009), No. 27, p. 2381.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuang, Cf., Zheng, Zw., Zhang, Gt. et al. Effects of overaging temperature on the microstructure and properties of 600 MPa cold-rolled dual-phase steel. Int J Miner Metall Mater 23, 943–948 (2016). https://doi.org/10.1007/s12613-016-1310-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1310-4