Abstract

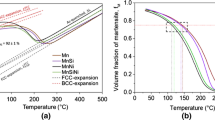

Silicon is an essential alloying element added in quenching and partitioning (Q&P) steels to delay and/or suppress carbide precipitation. However, there is a strong industrial interest to reduce the silicon content as it has detrimental effects on the metallurgical route. This work investigates by means of in situ high-energy XRD (HEXRD) the effect of silicon on the microstructural evolution during quenching and partitioning of a commercial 0.2C-2.3Mn grade. The results of this study highlight the role of the bainite transformation during the reheating and partitioning steps for effective austenite retention. Silicon influences the kinetics of austenite decomposition into bainite and finally promotes the stabilization of austenite. This is explained by the ability of silicon to suppress carbide precipitation (i) at the interface between bainite and austenite and (ii) in the martensite matrix. Carbide precipitation at the bainite/austenite interface decreases the amount of carbon that diffuses from bainite to austenite, subsequently accelerating the bainite transformation kinetics and preventing austenite stabilization. Carbide precipitation in martensite reduces the amount of carbon available for partitioning in austenite, further preventing its stabilization. Additions of elements such as Cr or Mo could be therefore considered in order to reduce the austenite decomposition in low-silicon steel grades.

Similar content being viewed by others

References

1. J. Speer, D. K. Matlock, B. C. De Cooman, and J. G. Schroth, Acta Mater., 2003, vol. 51, pp 2611-2622

2. J. G. Speer, D. V. Edmonds, F. C. Rizzo, and D. K. Matlock, Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 219-237.

3. M. J. Santofimia, L. Zhao, R. Petrov, C. Kwakernaak, W. G. Sloof, and J. Sietsma, Acta Mater., 2011, vol. 59, pp. 6059-6068.

4. D. De Knijf, C. Föjer, L.A.I. Kestens, and R. Petrov, Mater. Sci. Eng. A, 2015, vol. 638, pp. 219–227.

5. N.H. Van Dijk, A.M. Butt, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, and S. Van Der Zwaag, Acta Mater., 2005, vol. 53, pp. 5439–5447.

6. X.C. Xiong, B. Chen, M.X. Huang, J.F. Wang, and L. Wang, Scr. Mater., 2013, vol. 68, pp. 321–324.

P.J. Jacques, F. Delannay, and J. Ladrière: Metall. Mater. Trans. A Phys., 2001, vol. 32, pp. 2759–68.

8. H.S. Zhao, W. Li, X. Zhu, X.H. Lu, L. Wang, S. Zhou, and X.J. Jin, Mater. Sci. Eng. A, 2016, vol. 649, pp. 18–26.

9. L. Samek, E. De Moor, J. Penning, and B.C. De Cooman, Metall. Mater. Trans. A, 2006, vol. 37, pp. 109–124.

J. G. Speer, A. M. Streicher, D. K. Matlock, F. Rizzo, and G. Krauss (2003). Austenite formation and decomposition. Chicago, TMS Warrendale, pp 505-522

11. E. Girault, A. Mertens, P. Jacques, Y. Houbaert, B. Verlinden, and J. Van Humbeeck, Scr. Mater., 2001, vol. 44, pp. 885–892.

12. H.K.D.H. Bhadeshia and D. V. Edmonds, Metall. Trans. A, 1979, vol. 10, pp. 895–907.

13. M. Takahashi and H.K.D.H. Bhadeshia, Mater. Trans. JIM, 1991, vol. 32, pp. 689–696.

14. E. Kozeschnik and H.K.D.H. Bhadeshia, Mater. Sci. Technol., 2008, vol. 24, pp. 343–347.

15. A.J. Clarke, J.G. Speer, M.K. Miller, R.E. Hackenberg, D. V. Edmonds, D.K. Matlock, F.C. Rizzo, K.D. Clarke, and E. De Moor, Acta Mater., 2008, vol. 56, pp. 16–22.

16. J. Tobata, K.-L. Ngo-Huynh, N. Nakada, T. Tsuchiyama, and S. Takaki, ISIJ Int., 2012, vol. 52, pp. 1377–1382.

P.J. Jacques, E. Girault, A. Mertens, B. Verlinden, J. Van Humbeeck, and F. Delannay, ISIJ Int., 2001, vol. 41, pp. 1068–74.

18. Y. Toji, G. Miyamoto, and D. Raabe, Acta Mater., 2015, vol. 86, pp. 137–147.

19. D.T. Pierce, D. R. Coughlin, D. L. Williamson, K. D. Clarke, A. J. Clarke, J. G. Speer, and E. De Moor, Acta Mater., 2014, vol. 90, pp. 417-430.

20. F. HajyAkbary, J. Sietsma, G. Miyamoto, T. Furuhara, and M.J. Santofimia, Acta Mater., 2016, vol. 104, pp. 72–83.

21. P. Huyghe, L. Malet, M. Caruso, C. Georges, and S. Godet, Mater. Sci. Eng. A, 2017, vol. 701, pp. 254–263.

22. P. Huyghe, M. Caruso, J. L. Collet, S. Dépinoy, and S. Godet, Mater. Sci. Eng. A, 2019, vol. 743, pp. 175–184

S. Allain, G. Geandier, J.-C. Hell, M. Soler, F. Danoix, and M. Gouné, Metals, 2017, vol. 7, 232

24. M.J. Santofimia, T. Nguyen-Minh, L. Zhao, R. Petrov, I. Sabirov, and J. Sietsma, Mater. Sci. Eng. A, 2010, vol. 527, pp. 6429–6439.

G.K. Bansal, V. Rajinikanth, C. Ghosh, V.C. Srivastava, S. Kundu, and S. Ghosh Chowdhury: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 3501–14.

26. G.K. Bansal, M. Pradeep, C. Ghosh, V. Rajinikanth, V.C. Srivastava, A.N. Bhagat, and S. Kundu, Metall. Mater. Trans. A, 2019, vol. 50, pp. 547–555.

27. B. Kim, J. Sietsma, and M.J. Santofimia, Mater. Des., 2017, vol. 127, pp. 336–345.

28. P. Jacques, E. Girault, T. Catlin, N. Geerlofs, T. Kop, S. van der Zwaag, and F. Delannay, Mater. Sci. Eng. A, 1999, vol. 273–275, pp. 475–479.

T. Sourmail and M. Millot-Méheux, Mater. Sci. Technol. U.K., 2016, vol. 32, pp. 1126–32.

30. D.H. Kim, J.G. Speer, H.S. Kim, and B.C. De Cooman, Metall. Mater. Trans. A, 2009, vol. 40, pp. 2048–2060.

31. W.T. Zhao, X.F. Huang, and W.G. Huang, Mater. Sci. Technol., 2016, vol. 32, pp. 1374–81.

32. D.K. Matlock, V.E. Bräutigam, and J.G. Speer, Mater. Sci. Forum, 2003, vol. 426–432, pp. 1089–94.

33. S.M.C. van Bohemen, Mater. Sci. Technol., 2012, vol. 28, pp. 487–95.

34. K.W. Andrews, J. Iron Steel Inst., 1965, vol. 203, pp. 721–9.

ESRF Fit2D, http://www.esrf.eu/computing/scientific/FIT2D/. Accessed 20 November 2018

S.Y.P. Allain, G. Geandier, J.C. Hell, M. Soler, F. Danoix, and M. Gouné: Scr. Mater., 2017, vol. 131, pp. 15–18.

37. J. Epp, T. Hirsch, and C. Curfs, Metall. Mater. Trans. A, 2012, vol. 43, pp. 2210–2217.

38. J. Epp, H. Surm, O. Kessler, and T. Hirsch, Acta Mater., 2007, vol. 55, pp. 5959–5967.

39. X.G. Lu, M. Selleby, and B. Sundman, Acta Mater., 2005, vol. 53, pp. 2259–2272.

40. Y. Toji, H. Matsuda, M. Herbig, P.-P. Choi, and D. Raabe, Acta Mater., 2014, vol. 65, pp. 215–228.

J. Drumond, O. Girina, J.F. de Filho, N. Fonstein, and C.A.S. de Oliveira, Metallogr. Microstruct. Anal., 2012, vol. 1, pp. 217–23.

42. D. Quidort and Y.J.M. Brechet, Acta Mater., 2001, vol. 49, pp. 4161–4170.

43. D. Quidort and Y. Bréchet, Scr. Mater., 2002, vol. 47, pp. 151–156.

Acknowledgments

We thank the European Synchrotron Radiation Facility for the provision of synchrotron radiation facilities and would also like to thank P. Sedmak and T. Buslaps for assistance in using beamline ID11.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 21, 2018.

Rights and permissions

About this article

Cite this article

Huyghe, P., Caruso, M., Collet, JL. et al. In Situ Quantitative Assessment of the Role of Silicon During the Quenching and Partitioning of a 0.2C Steel. Metall Mater Trans A 50, 3486–3494 (2019). https://doi.org/10.1007/s11661-019-05281-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05281-2