Abstract

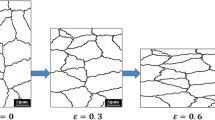

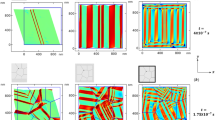

The temporal evolution of microstructures and carbon distributions in a Fe-0.323C-1.231Mn-0.849Si (mol pct) dual-phase steel during heat treatments are simulated using a two-dimensional cellular automaton model. The model involves austenite nucleation, phase transformations controlled by ferrite (α)/austenite (γ) interface mobility and the local carbon concentration, and long-range carbon diffusion. It is also coupled with a solute drag model to account for the effect of substitutional elements on the interface migration. The results show that after holding at 800 °C for 300 seconds the transformed γ-volume fraction is lower than the paraequilibrium prediction. During subsequent cooling at 6 °C s−1, the γ → α transformation takes place after a stagnant stage; the carbon concentrations in both the α- and γ-phases increase and become non-uniform. When cooled below 450 °C, the γ-volume fraction is nearly unchanged. A small amount of carbon enriched martensite, transformed from the remaining γ-phase, exists in the room temperature microstructure. The simulated microstructures and carbon concentrations in martensite compare reasonably well with the experimental micrographs and atom-probe tomographic measurements. During tempering at 400 °C, martensite decomposes and the carbon concentration in the α-matrix increases. The simulation results are used to understand the mechanisms of yield strength variations after different heat treatments.

Similar content being viewed by others

References

[1] M. Gouné, F. Danoix, J. Ågren, Y. Bréchet, C.R. Hutchinson, M. Militzer, G. Purdy, S. van der Zwaag, and H. Zurob: Mater. Sci. Eng. R-Rep., 2015, vol. 92, pp. 1–38.

[2] C.C. Tasan, M. Diehl, D. Yan, M. Bechtold, F. Roters, L. Schemmann, C. Zheng, N. Peranio, D. Ponge, M. Koyama, K. Tsuzaki, and D. Raabe: Annu. Rev. Mater. Res., 2015, vol. 45, pp. 391–431.

[3] G. Krauss: Steels: Processing, Structure, and Performance, Second Edition, ASM International, Materials Park, Ohio, 2015.

[4] J. Sietsma and S. van der Zwaag: Acta Mater., 2004, vol. 52, pp. 4143–52.

[5] C. Bos and J. Sietsma: Scr. Mater., 2007, vol. 57, pp. 1085–8.

[6] M.G. Mecozzi, C. Bos, and J. Sietsma: Acta Mater., 2015, vol. 88, pp. 302–13.

[7] A. Hultgren: Trans. ASM., 1947, vol. 39, pp. 915–1005.

[8] G.R. Purdy and Y.J.M. Brechet: Acta Metall. Mater., 1995, vol. 43, pp. 3763–74.

[9] H. Chen and S. van der Zwaag: Acta Mater., 2014, vol. 72, pp. 1–12.

[10] Z.Q. Liu, G. Miyamoto, Z.G. Yang, and T. Furuhara: Acta Mater., 2013, vol.61, pp. 3120–9.

[11] Y. Kubo, K. Hamada, and A. Urano: Ultramicroscopy, 2013, vol. 135, pp. 64–70.

[12] T.F. Kelly and M.K. Miller: Rev. Sci. Instrum., 2007, vol. 78, p. 031101.

[13] D.N. Seidman: Annu. Rev. Mater. Res., 2007, vol. 37, pp. 127–58.

[14] Y.R. Wen, Y.P. Li, A. Hirata, Y. Zhang, T. Fujita, T. Furuhara, C.T. Liu, A. Chiba, and M.W. Chen: Acta Mater., 2013, vol. 61, pp. 7726–40.

[15] Y. Toji, H. Matsuda, M. Herbig, P.-P. Choi, and D. Raabe: Acta Mater., 2014, vol. 65, pp. 215–28.

[16] M.I. Hartshorne, D. Isheim, D.N. Seidman, and M.L. Taheri: Ultramicroscopy, 2014, vol. 147, pp. 25–32.

[17] S.-I. Baik, L. Ma, Y.-J. Kim, B. Li, M. Liu, D. Isheim, B.I. Yakobson, P.M. Ajayan, and D.N. Seidman: Small, 2015, vol. 11, pp. 5968–74.

[18] J. Rudnizki, B. Böttger, U. Prahl, and W. Bleck: Metall. Mater. Trans. A, 2011, vol. 42, pp. 2516–25.

[19] C. Zheng and D. Raabe: Acta Mater., 2013, vol. 61, pp. 5504–17.

[20] B. Su, Z. Han, and B. Liu: ISIJ Int., 2013, vol. 53, pp. 527–34.

[21] B. Zhu, Y. Zhang, C. Wang, P.X. Liu, W.K. Liang, and J. Li: Metall. Mater. Trans. A, 2014, vol. 45, pp. 3161–71.

[22] G. Zhu, Y. Kang, C. Lu, and S. Li: Steel Res. Int., 2014, vol. 85, pp. 1035–46.

[23] M. Militzer, M.G. Mecozzi, J. Sietsma, and S. van der Zwaag: Acta Mater., 2006, vol. 54, pp. 3961–72.

[24] D.Z. Li, N.M. Xiao, Y.J. Lan, C.W. Zheng, and Y.Y. Li: Acta Mater., 2007, vol. 55, pp. 6234–49.

[25] D.S. Svyetlichnyy and A.I. Mikhalyov: ISIJ Int., 2014, vol. 54, pp. 1386–95.

[26] B. Su, Q. Ma, and Z. Han: Steel Res. Int., 2017, vol. 88, p. 1600490.

[27] C. Bos, M.G. Mecozzi, and J. Sietsma: Comput. Mater. Sci., 2010, vol. 48, pp. 692–9.

[28] B. Zhu and M. Militzer: Metall. Mater. Trans. A, 2015, vol. 46, pp. 1073–84.

[29] B. Zhu, H. Chen, and M. Militzer: Comput. Mater. Sci., 2015, vol. 108, pp. 333–41.

[30] H. Chen, B. Zhu, and M. Militzer: Metall. Mater. Trans. A, 2016, vol. 47, pp. 3873–81.

[31] D. An, S. Pan, L. Huang, T. Dai, B. Krakauer, and M. Zhu: ISIJ Int., 2014, vol. 54, pp. 422–9.

Image Tool Program. University of Texas Health Science Center, San Antonio, 2002. http://compdent.uthscsa.edu/dig/itdesc.html. Accessed 05 March 2018.

[33] G. Krauss: Mater. Sci. Eng. A, 1999, vol. 273–275, pp. 40–57.

[34] G.R. Speich and W.C. Leslie: Metall. Trans., 1972, vol. 3, pp. 1043–54.

G.F. Vander Voort: Atlas of Time-Temperature Diagrams for Irons and Steels, ASM International, Materials Park, Ohio, 1991.

[36] O.C. Hellman, J.A. Vandenbroucke, J. Rüsing, D. Isheim, and D.N. Seidman: Microsc. Microanal., 2000, vol. 6, pp. 437–44.

[37] P.H. Chang and A.G. Preban: Acta Metall., 1985, vol. 33, pp. 897–903.

[38] A.H. Cottrell and B.A. Bilby: Proc. Phys. Soc. Sect. A, 1949, vol. 62, pp. 49–62.

[39] E.O. Hall: Yield Point Phenomena in Metals and Alloys, Springer US, Boston, MA, 1970.

[40] R. Rementeria, J.D. Poplawsky, M.M. Aranda, W. Guo, J.A. Jimenez, C. Garcia-Mateo, and F.G. Caballero: Acta Mater., 2017, vol. 125, pp. 359–68.

[41] V.I. Savran, S.E. Offerman, and J. Sietsma: Metall. Mater. Trans. A, 2010, vol. 41, pp. 583–91.

[42] G.S. Huppi, D.K. Matlock, and G. Krauss: Scr. Metall., 1980, vol. 14, pp. 1239–43.

[43] G.P. Krielaart and S. Van Der Zwaag: Mater. Sci. Technol., 1998, vol. 14, pp. 10–8.

[44] F. Fazeli and M. Militzer: Metall. Mater. Trans. A, 2005, vol. 36, pp. 1395–405.

[45] J.R. Bradley and H.I. Aaronson: Metall. Trans. A, 1977, vol. 8, pp. 317–22.

[46] C. Capdevila, F.G. Caballero, and C.G. de Andrés: ISIJ Int., 2002, vol. 42, pp. 894–902.

[47] L. Cheng, C.M. Brakman, B.M. Korevaar, and E.J. Mittemeijer: Metall. Trans. A, 1988, vol. 19, pp. 2415–26.

[48] T. Waterschoot, K. Verbeken, and B.C. De Cooman: ISIJ Int., 2006, vol. 46, pp. 138–46.

[49] D. Isheim, A.H. Hunter, X.J. Zhang, and D.N. Seidman: Metall. Mater. Trans. A, 2013, vol. 44, pp. 3046–59.

[50] D. Jain, D. Isheim, X.J. Zhang, G. Ghosh, and D.N. Seidman: Metall. Mater. Trans. A, 2017, vol. 48, pp. 3642–54.

[51] K. Thompson, P.L. Flaitz, P. Ronsheim, D.J. Larson, and T.F. Kelly: Science, 2007, vol. 317, pp. 1370–74.

[52] A. Kwiatkowski da Silva, G. Leyson, M. Kuzmina, D. Ponge, M. Herbig, S. Sandlöbes, B. Gault, J. Neugebauer, and D. Raabe: Acta Mater., 2017, vol. 124, pp. 305–15.

Acknowledgments

This work was financially supported by A. O. Smith Corporation, USA, NSFC (Grant Nos. 51371051, 51501091), the Jiangsu Key Laboratory for Advanced Metallic Materials (BM2007204), and the Scientific Research Foundation of Graduate School of Southeast University (YBJJ1628). Mr. Dong An is grateful for the financial support from the China Scholarship Council (CSC). APT was performed at the Northwestern University Center for Atom-Probe Tomography (NUCAPT). The LEAP tomograph at NUCAPT was purchased and upgraded with Grants from the NSF-MRI (DMR-0420532) and ONR-DURIP (N00014-0400798, N00014-0610539, N00014-0910781, N00014-1712870) Programs. This work made use of the EPIC Facility of Northwestern University’s NUANCE Center. NUCAPT and NUANCE received support through the MRSEC Program (NSF DMR-1720139) at the Materials Research Center and the SHyNE Resource (NSF ECCS-1542205), NUCAPT from the Initiative for Sustainability and Energy (ISEN), at Northwestern University; NUANCE from the International Institute for Nanotechnology (IIN); the Keck Foundation; and the State of Illinois, through the IIN.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 29, 2018.

Rights and permissions

About this article

Cite this article

An, D., Baik, SI., Pan, S. et al. Evolution of Microstructure and Carbon Distribution During Heat Treatments of a Dual-Phase Steel: Modeling and Atom-Probe Tomography Experiments. Metall Mater Trans A 50, 436–450 (2019). https://doi.org/10.1007/s11661-018-4975-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4975-7