Abstract

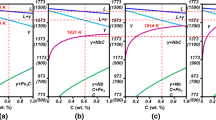

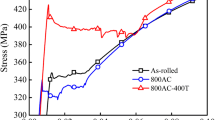

A 3D cellular automaton finite element model with full coupling of heat, flow, and solute transfer incorporating solidification grain nucleation and growth was developed for a multicomponent system. The predicted solidification process, shrinkage porosity, macrosegregation, grain orientation, and microstructure evolution of Fe-22Mn-0.7C twinning-induced plasticity (TWIP) steel match well with the experimental observation and measurement. Based on a new solute microsegregation model using the finite difference method, the thermophysical parameters including solid fraction, thermal conductivity, density, and enthalpy were predicted and compared with the results from thermodynamics and experiment. The effects of flow and solute transfer in the liquid phase on the solidification microstructure of Fe-22Mn-0.7C TWIP steel were compared numerically. Thermal convection decreases the temperature gradient in the liquid steel, leading to the enlargement of the equiaxed zone. Solute enrichment in front of the solid/liquid interface weakens the thermal convection, resulting in a little postponement of columnar-to-equiaxed transition (CET). The CET behavior of Fe-Mn-C TWIP steel during solidification was fully described and mathematically quantized by grain morphology statistics for the first time. A new methodology to figure out the CET location by linear regression of grain mean size with least-squares arithmetic was established, by which a composition design strategy for Fe-Mn-C TWIP steel according to solidification microstructure, matrix compactness, and homogeneity was developed.

Similar content being viewed by others

Abbreviations

- CET:

-

Columnar-to-equiaxed transition

- FEEDLEN:

-

Length of liquid steel feeding

- HTC:

-

Heat-transfer coefficient

- MACROFS:

-

Critical solid fraction for macroshrinkage

- TWIP:

-

Twinning-induced plasticity

- a :

-

Temperature coefficient in calculating thermal conductivity

- a 2 :

-

Kinetics coefficients of dendrite tip growth

- a 3 :

-

Kinetics coefficients of dendrite tip growth

- a γ :

-

Parameter in calculating enthalpy

- b :

-

Solute concentration coefficient in calculating thermal conductivity

- c p :

-

Specific heat

- c 0 :

-

Initial solute concentration

- D :

-

Diffusion coefficient

- f :

-

Solid fraction

- f t v :

-

Solid fraction at step t for cell v

- f t+δt v :

-

Solid fraction at step t + δt for cell v

- δf v :

-

Solid fraction change or cell v

- G :

-

Temperature gradient

- H :

-

Enthalpy

- δH :

-

Enthalpy change in micro-time-step

- δH v :

-

Enthalpy change in micro-time-step for cell v

- δH n :

-

Enthalpy change in micro-time-step for the element n

- k :

-

Equilibrium solid/liquid partition coefficient

- K :

-

Thermal conductivity

- L :

-

Liquid phase

- M :

-

Mass

- m :

-

Slope of the liquidus line in phase diagram

- n :

-

Number of the element containing the cell v

- t :

-

Time-step

- T :

-

Temperature

- T L :

-

Liquidus

- T S :

-

Solidus

- T m :

-

Melting temperature for pure ferrite

- T eutectic :

-

Eutectic temperature

- T t v :

-

Temperature at step t for cell v

- T t+δt v :

-

Temperature at step t + δt for cell v

- δT v :

-

Temperature change or cell v

- δt :

-

Micro-time-step

- υ :

-

Dendrite growth rate

- ∆T :

-

Undercooling

- ∆H f :

-

Latent heat of per unit volume

- v :

-

Cell number

- ϕ vn :

-

Interpolation coefficient of element n and cell v

- ρ :

-

Density

References

O. Grässel and G. Frommeyer: Mater. Sci. Technol., 1998, vol. 14 (12), pp. 1213–17.

O. Grässel, L. Krüger, G. Frommeyer et al.: Int. J. Plast., 2000, 16 (10), pp. 1391–1409.

U. Brüx, G. Frommeyer, O. Grässel et al.: Steel Res., 2002, vol. 73 (13), pp. 294–98.

G. Frommeyer, U. Brüx, and P. Neumann: ISIJ Int., 2003, vol. 43 (3), pp. 438–46.

S. Vercammen, B. Blanpain, B.C. De Cooman et al.: Acta Mater., 2004, vol. 52 (7), pp. 2005–12.

S. Vercammen, B.C. De Cooman, and N. Akdut: Steel Res. Int., 2003, vol. 74 (6), pp. 370–75.

A.A. Saleh, E.V. Pereloma, and A.A. Gazder: Mater. Sci. Eng. A, 2011, vol. 528 (13–14), pp. 4537–49.

D.B. Santos, A.A. Saleh, A.A. Gazder et al.: Mater. Sci. Eng. A, 2011, vol. 528 (13–14), 3545–55.

Z. Mi, D. Tang, L. Yan et al.: J. Mater. Sci. Technol., 2005, vol. 21 (4), pp. 451–54.

K. Phiu-on, W. Bleck, A. Schwedt et al.: Steel Res. Int., 2009, vol. 80 (1), pp. 29–38.

M. Eskandari, A. Zarei-Hanzaki, and A. Marandi: Mater. Des., 2012, vol. 39, pp. 279–84.

M. Ha, W.S. Kim, H.K. Moon et al.: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1087–98.

K.H. Spitzer, F. Ruppel, R. Viscorova et al. (2003) Steel Res. Int., 74 (11–12):724–31.

Y.N. Dastur and W.C. Leslie: Metall. Trans. A, 1981, vol. 12, pp. 749–59.

B.K. Zuidema, D.K. Subramanyam, and W.C. Leslie: Metall. Trans. A, 1987, vol. 8A, pp. 1629–39.

I. Karaman, H. Sehitoglu, K. Gall et al.: Acta Mater., 2000, vol. 48 (6), pp. 1345–59.

C. Scott, S. Allain, M. Faral et al.: Rev. Métall., 2006, vol. 103, no. 6, pp. 293–302.

Y.G. Kim, J.K. Han, and E.W. Lee: Metall. Mater. Trans. A, 1986, vol. 17A, pp. 2097–98.

Y.G. Kim and C.Y. Lim: Metall. Mater. Trans. A, 1988, vol. 19A, pp. 1625–26.

Y.G. Kim, Y.S. Park, and J.K. Han: Metall. Mater. Trans. A, 1985, vol. 16A, pp. 1689–93.

J.M. Han and Y.G. Kim: J. Mater. Sci. Lett., 1989, vol. 8 (5), pp. 599–601.

K.H. Hwang, W.S. Yang, T.B. Wu et al.: Acta Metall. Mater., 1991, vol. 39 (5), pp. 825–31.

K.H. Hwang, C.M. Wan, and J.G. Byrne: Mater. Sci. Eng. A, 1991, vol. 132, pp. 161–69.

T. Shun, C.M. Wan, and J.G. Byrne: Acta Metall. Mater., 1992, vol. 40 (12), pp. 3407–12.

O. Bouaziz and N. Guelton: Mater. Sci. Eng. A, 2001, vol. 319, pp. 246–49.

A. Dumay, J.P. Chateau, S. Allain et al.: Mater. Sci. Eng. A, 2008, vol. 483, pp. 184–87.

S. Allain, J.P. Chateau and O. Bouaziz: Mater. Sci. Eng. A, 2004, vol. 387, pp. 143–47.

S. Allain, J.P. Chateau, D. Dahmoun et al.: Mater. Sci. Eng. A, 2004, vol. 387, pp. 272–76.

L. Bracke, K. Verbeken, L. Kestens et al.: Acta Mater., 2009, vol. 57 (5), pp. 1512–24.

L. Bracke, L. Kestens, and J. Penning: Scripta Mater., 2009, vol. 61 (2), pp. 220–22.

R. Ueji, N. Tsuchida, D. Terada et al.: Scripta Mater., 2008, vol. 59 (9), pp. 963–66.

J.D. Yoo, S.W. Hwang, and K.T. Park: Mater. Sci. Eng. A, 2009, vol. 508 (1), pp. 234–40.

J.E. Jin and Y.K. Lee: Mater. Sci. Eng. A, 2009, vol. 527 (1), pp. 157–61.

M. Koyama, T. Sawaguchi, and K. Tsuzaki: ISIJ Int., 2012, vol. 52 (1), pp. 161–63.

M. Koyama, T. Sawaguchi, and K. Tsuzaki: ISIJ Int., 2013, vol. 53 (2), pp. 323–29.

S.C. Mittal, R.C. Prasad, and M.B. Deshmukh: ISIJ Int., 1995, vol. 35 (3), pp. 302–08.

R.T. Van Tol, L. Zhao, H. Schut et al.: Mater. Sci. Technol., 2012, vol. 28 (3), pp. 348–53.

K.H. So, J.S. Kim, Y.S. Chun et al.: ISIJ Int., 2009, vol. 49 (12), pp. 1952–59.

M. Koyama, E. Akiyama, and K. Tsuzaki: Corros. Sci., 2012, vol. 54, pp. 1–4.

M. Koyama, E. Akiyama, T. Sawaguchi et al.: Scripta Mater., 2012, vol. 66 (7), pp. 459–62.

M. Koyama, E. Akiyama, and K. Tsuzaki: Scripta Mater., 2012, vol. 66 (11), pp. 947–50.

S.H. Wang, Z.Y. Liu, W.N. Zhang et al.: ISIJ Int., 2009, vol. 49 (9), pp. 1340–46.

M. Daamen, B. Wietbrock, S. Richter et al.: Steel Res. Int., 2011, vol. 82 (1), pp. 70–75.

Y. Saito, G. Goldbeck-Wood, and H. Müller-Krumbhaar: Phys. Rev. A, 1988, vol. 38 (4), pp. 2148–53.

D. Juric and G. Tryggvason: J. Comput. Phys., 1996, vol. 123 (1), pp. 127–48.

G. Caginalp and P. Fife: Phys. Rev. B, 1986, vol. 33 (11), pp. 7792–94.

R. Kobayashi: Phys. D, 1993, vol. 63 (3), pp. 410–23.

J.A. Spittle and S.G. Brown: Acta Metall., 1989, vol. 37 (7), pp. 1803–10.

P.P. Zhu and R.W. Smith: Acta Metall., 1992, vol. 40 (4), pp. 683–92.

C.A. Gandin and M. Rappaz: Acta Metall., 1994, vol. 42 (7), pp. 2233–46.

C.A. Gandin, J.L. Desbiolles, M. Rappaz et al.: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3153–65.

L. Nastac and D.M. Stefanescu: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 4061–74.

L. Nastac and D.M. Stefanescu: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 4075–83.

M. Yamazaki, Y. Natsume, H. Harada et al.: ISIJ Int., 2006, vol. 46 (6), pp. 903–08.

J. Wang, F. Wang, C. Li et al.: ISIJ Int., 2010, vol. 50 (2), pp. 222–30.

C. Jing, Z. Xu, Y. Wang et al.: China Foundry, 2012, vol. 9 (1), pp. 53–59.

Z. Hou, F. Jiang, and G. Cheng: ISIJ Int., 2012, vol. 52 (7), pp. 1301–09.

P. Lan, L. Song, C. Du et al.: Mater. Sci. Technol., 2014, vol. 30 (11), pp. 1297–1304.

D. Djurovic, B. Hallstedt, J. von Appen et al.: Calphad, 2011, vol. 35 (4), pp. 479–91.

W. Huang: Metall. Trans. A, 1990, vol. 21A, pp. 2115–23.

H. Qian, P. Lan, J. Zhang et al.: Special Steel, 2010, vol. 31 (2), pp. 25–28 (in Chinese)

G. Engstrom, H. Fredriksson, and B. Rogberg: Scand. J. Metall., 1983, vol. 12 (1), pp. 3–12.

K. Harste: Ph.D. Dissertation, Technical University of Clausthal, Clausthal-Zellerfeld, 1989.

A. Jablonka, K. Harste, and K. Schwerdtfeger: Steel Res., 1991, vol. 62 (1), pp. 24–33.

H. Mizukami, A. Yamanaka, and T. Watanabe: ISIJ Int., 2002, vol. 42 (4), pp. 375–84.

P. Lan and J. Zhang: Steel Res. Int., 2016, vol. 87 (2), pp. 250–61.

L. Yang: Master Thesis, University of Science and Technology Beijing, Beijing, 2012.

J. Yang, Y.N. Wang, X.M. Ruan et al.: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1365–75.

P. Lan and J. Zhang: Ironmaking and Steelmaking, 2014, vol. 41 (8), pp. 598–606.

P. Lan, H. Sun, Y. Li, et al. (2014) J. Univ. Sci. Technol. Beijing, 36(3):315–22

J. Miettinen: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 365–79.

I. Hitoshi, N. Yukinobu, and O. Kenichi: ISIJ Int., 2008, vol. 48 (12), pp. 1728–33.

C. Jing, X. Wang, M. Jiang et al.: Steel Res Int., 2011, vol. 82 (10), pp. 1173–79.

L. Bai, H. Liu, Y. Zhang et al. (2011) J. Univ. Sci. Technol. Beijing 33(9):1091–98

J. Wang, F. Wang, Y. Zhao et al.: Int. J. Min. Metall. Mater., 2009, vol. 16 (6), pp. 640–45.

M.C. Schneider and C. Beckermann: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 2373–88.

Y. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 685–705.

M. Rappaz and C.A. Gandin: Acta Metall., 1993, vol. 41(2), pp. 345–60.

C. Pequet, M. Rappaz, and M. Gremaud: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2095–2106.

ProCAST User Manual, ESI group. The virtual try-out space company, 2011.

E. Scheil: Z. Metallkd., 1942, vol. 34 (3), pp. 70–72.

P. Lan, Y. Li, J. Zhang et al.: EPD Congress TMS2012, John Wiley & Sons, Inc., New York, NY, 2012, pp. 71–78.

P. Lan and J. Zhang: Mater. Des., 2014, vol. 53, pp. 822–29.

P. Lan and J. Zhang: Mater. Des., 2014, vol. 54, pp. 112–24.

J.D. Hunt: Mater. Sci. Eng., 1984, vol. 65 (1), pp. 75–83.

S.C. Flood and J.D. Hunt: J Cryst. Growth, 1987, vol. 82 (3), pp. 552–60.

Z. Hou, G. Cheng, F. Jiang et al.: ISIJ Int., 2013, vol. 53 (4), pp. 655–64.

C. Wang, H. Gao, Y. Dai et al.: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 1616–20.

S. Tsuchiya, M. Ohno, and K. Matsuura: Acta Mater., 2012, vol. 60 (6), pp. 2927–38.

M. Ohno, M. Maruyama, and K. Matsuura: Metall. Mater. Trans. A, 2015, vol. 46 (11), pp. 5240–47.

S.K. Choudhary and A. Ghosh: ISIJ Int., 1994, vol. 34 (4), pp. 338–45.

M.R. Bridge and G.D. Rogers: Metall. Trans. B, 1984, vol. 15B, pp. 581–89.

K.A. Jackson, J.D. Hunt, D.R. Uhlmann et al.: Trans. AIME, 1966, vol. 236 (2), pp. 149–58

Q. Han, H. Hu (1989) Acta Metall. Sinica Engl. Ed. B 2 (2):94–98.

H. Xu, L.D. Xu, S.J. Zhang et al.: Scripta Mater., 2006, vol. 54 (12), pp. 2191–96.

Y. Shan, X. Luo, X. Hu et al.: J. Mater. Sci. Technol., 2011, vol. 27 (4), pp. 352–58.

M. El-Bealy and B.G. Thomas: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 689–93.

H. Jacobi and K. Schwerdtfeger: Metall. Trans. A, 1976, vol. 7A, pp. 811–20.

H. Mizukami, K. Hayashi, M. Numata et al.: ISIJ Int., 2012, vol. 52 (12), pp. 2235–44.

S. Tsuchiya, M. Ohno, and K. Matsuura: Acta Mater., 2012, vol. 60 (6), pp. 2927–38.

H. Suito, H. Ohta, and S. Morioka: ISIJ Int., 2006, vol. 46 (6), pp. 840–46.

J.D. Hunt: Solidification and Casting of Metals, Metals Society, London, 1979.

W. Kurz and D.J. Fisher: Acta Metall., 1981, vol. 29 (1), pp. 11–20.

S. Ilie, H. Presslinger, P. Reisinger et al.: Steel Res. Int., 2007, vol. 78 (4), pp. 327–32.

Acknowledgments

This research was carried out in the School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing. The authors gratefully acknowledge the financial support of the Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-15-066A1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 14, 2013.

Rights and permissions

About this article

Cite this article

Lan, P., Tang, H. & Zhang, J. Solidification Microstructure, Segregation, and Shrinkage of Fe-Mn-C Twinning-Induced Plasticity Steel by Simulation and Experiment. Metall Mater Trans A 47, 2964–2984 (2016). https://doi.org/10.1007/s11661-016-3445-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3445-3