Abstract

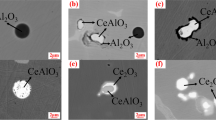

The role of Nb in normalized and tempered Ti-bearing 13Cr5Ni2Mo super martensitic stainless steel is investigated through in-depth characterization of the bimodal chemistry and size of Nb-rich precipitates/atomic clusters and Nb in solid solution. Transmission electron microscopy and atom probe tomography are used to analyze the samples and clarify precipitates/atom cluster interactions with dislocations and austenite grain boundaries. The effect of 0.1 wt pct Nb addition on the promotion of (Ti, Nb)N-Nb(C,N) composite precipitates, as well as the retention of Nb in solution after cooling to room temperature, are analyzed quantitatively. (Ti, Nb)N-Nb(C,N) composite precipitates with average diameters of approximately 24 ± 8 nm resulting from epitaxial growth of Nb(C,N) on pre-existing (Ti,Nb)N particles, with inter-particle spacing on the order of 205 ± 68 nm, are found to be associated with mean austenite grain size of 28 ± 10 µm in the sample normalized at 1323 K (1050 °C). The calculated Zener limiting austenite grain size of 38 ± 13 µm is in agreement with the experimentally observed austenite grain size distribution. 0.08 wt pct Nb is retained in the as-normalized condition, which is able to promote Nb(C, N) atomic clusters at dislocations during tempering at 873 K (600 °C) for 2 hours, and increases the yield strength by 160 MPa, which is predicted to be close to maximum increase in strengthening effect. Retention of solute Nb before tempering also leads to it preferentially combing with C and N to form Nb(C, N) atom clusters, which suppresses the occurrence of Cr- and Mo-rich carbides during tempering.

Similar content being viewed by others

References

B. Qin, Z.Y. Wang and Q.S. Sun: Mater. Charact., 2008, vol. 59, pp. 1096–1100.

Y.Y. Song, D.H. Ping, F.X. Yin, X.Y. Li and Y.Y. Li: Mater. Sci. Eng. A, 2012, vol. 527, pp. 614-18.

P.D. Bilmes, C.L. Llorente, C.M. Méndez and C.A. Gervasi: Corrosion. Sci., 2009, vol. 51, pp. 876-81.

P.D. Bilmes, M. Solari and C.L. Llorente: Mater. Charact., 2001, vol. 46, pp. 285-96.

X.P. Ma, L.J. Wang, C.M. Liu and S.V. Subramanian: Mater. Sci. Eng. A, 2011, vol. 528, pp. 6812 – 18.

Xiaoping Ma, Lijun Wang, Sundaresa Subramanian and Chunming Liu: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4475-86.

E. Ladanova, J.K. Solberg and T. Rogne: Corrosion Eng. Sci. Technol., 2006, vol. 41, pp. 143–51.

B. Gault, M. Moody, J. Cairney and S.P. Ringer: Atom Probe Microscopy, Springer Science, New York, 2012.

B.P. Geiser, D.J. Larson, E. Oltman, S.S. Gerstl, D.A. Reinhard, T.F. Kelly and T.J. Prosa: Microsc. Microanal., 2009, vol. 15 (S2), pp. 292–93.

B. Gault, D. Haley, F. de Geuser, M.P. Moody, E.A. Marquis, D.J. Larson and B.P. Geiser: Ultramicrosc., 2011, vol. 111, pp. 448–57.

B. Gault, M.P. Moody, F. de Geuser, G. Tsafnat, A. La Fontaine, L.T. Stephenson, D. Haley and S.P. Ringer: J. Appl. Phys., 2009, 105:034913.

M. Hillert and L.I. Staffanson: Acta Chemica Scandinavica, 1970, vol. 24, pp. 3618–26.

H. Zou: Ph.D. thesis, McMaster University, Canada, 1991.

L. Ryde: Mater. Sci. Tech., 2006, vol. 22, pp. 1297–1306.

T. Gladman and F.B. Pickering: Yield, Flow and Fracture of Polycrystals, Applied Science Publishers, London, 1982, pp. 141-98.

S.V. Subramanian, F. Boratto, J.J. Jonas, C.M. Sellars: Proc. of Int. Symp. on Microalloyed Bar and Forging Steels, 1990, pp. 120–36.

S.G. Hong, K.B. Kang and C.G. Park: Scr. Mater., 2002, vol. 46, pp. 163-68.

T. Gladman: Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, U.K., 1997, pp. 82–87.

M. Kuzmina, M. Herbig, D. Ponge, S. Sandlobes and D. Raabe: Sci., 2015, vol. 349, pp. 1080–83.

G.D.W. Smith, D. Hudson, P.D. Styman and C.A. Williams: Philos. Mag., 2013, vol. 93, pp. 3726–40.

C.A. Williams, J.M. Hyde, G.D.W. Smith and E.A. Marquis: J. Nucl. Mater., 2011, vol. 412, pp. 100–05.

B. Gault, M.P. Moody, J.M. Cairney and S.P. Ringer: Mater. Today, 2012, vol. 15, pp. 378–86.

O.C. Hellman, J.A. Vandenbroucke, J. Rüsing, D. Isheim and D.N. Seidman: Microsc. Microanal., 2000, vol. 6, pp. 437–44.

P. Felfer, A. Ceguerra, S. Ringer and J. Cairney: Ultramicrosc., 2013, vol. 132, pp. 100–06.

P. Maugis and K. Hoummada: Scr. Mater., 2016, vol.120, pp. 90–93.

F. Danoix, E. Bémont, P. Maugis and D. Blavette: Adv. Eng. Mater., 2006, vol. 8, pp. 1202-05.

A. Deschamps, F. Danoix, F. De Geuser, T. Epicier, H. Leitner and M. Perez: Mater. Lett., 2011, vol.65, pp. 2265–68.

M. Perez, E. Courtois, D. Acevedo, T. Epicier and P. Maugis: Mater. Sci. Forum, 2007, vol. 539-543, pp. 4196-4201.

Bémont E. PhD. Rouen, Universite´ de Rouen, France, 2003.

E. Bémont, E. Cadel, P. Maugis, D. Blavette: Surf. Interface Anal., 2004, 36:585–88.

M.F. Ashby: 1 st Riso Int. Symp. on Metallurgy and Materials Science on Recrystallization and grain Growth in Multi-Phase Particle Containing Materials, 1980, pp. 325–36.

G.S. Rohrer: Trans. AIME, 1948, vol. 175, pp. 15–51, by C.S. Smith: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 1063–100.

J.W. Cahn: Acta Matell., 1962, vol. 10, pp. 789-98.

H.S. Zurob, G. Zhu, S.V. Subramanian, G.R. Purdy, C.R. Hutchinson and Y. Brechet: ISIJ Int., 2005, vol. 45, pp. 713-22.

P. Gong, E.J. Palmiere and W.M. Rainforth: Acta Mater., 2015, vol. 97, pp. 392-403.

M. Maalekian, R. Radis, M. Militzer, A. Moreau and W.J. Poole: Acta Mater., 2012, vol. 60, pp. 1015–26.

C. Fossaert, G. Rees, T. Maurickx and H.K.D.H. Bhadeshia: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 21-30.

S.V. Subramanian, X. Ma, K. Rehman: Proc. Energy Mater., Xi’an China, 2014.

M.T. Nagata, J.G. Speer and D.K. Matlock: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 3099-3110.

B. Dutta, E.J. Palmiere and C.M. Sellars: Acta Mater., 2001, vol. 49, pp. 785–94.

F. Perrard, A. Deschamps and P. Maugis: Acta Mater., 2007, vol. 55, pp. 1255–66.

F. Perrard, A. Deschamps, F. Bley, P. Donnadieu and P. Maugis: J. Appl. Crystallogr., 2006, vol. 39, pp. 473-82.

K.Y. Xie, T. Zheng, J.M. Cairney, H. Kaul, J.G. Williams, F.J. Barbaro, C.R. Killmore and S.P. Ringer: Scr. Mater., 2012, vol. 66, pp. 710-13.

T. Gladman: Mater. Sci. and Technol., 1999, vol. 15, pp. 30-36.

M.F. Ashby: On the Orowan stress, in: A.S. Argon (Ed.), Physics of Strength and Plasticity, MIT Press, Cambridge, 1969, pp.113-31.

A.J. Breen, K.Y. Xie, M.P. Moody, B. Gault, H.W. Yen, C.C. Wong, J.M. Cairney, and S.P. Ringer: Microsc. Microanal., 2014, vol. 20, pp. 1100-10.

S.L. Shrestha, K.Y. Xie, C. Zhu, S.P. Ringer, C. Killmore, K. Carpenter, H. Kaul, J.G. Williams and J.M. Cairney: Mater. Sci. Eng. A, 2013, vol. 568, pp. 88–95.

S.L. Shrestha, K.Y. Xie, S.P. Ringer, K.R. Carpenter, D.R. Smith, C.R. Killmore and J.M. Cairney: Scr. Mater., 2013, vol. 69, pp. 481–84.

A.G. Kostryzhev, A. Al Shahrani, C. Zhu, J.M. Cairney, S.P. Ringer, C.R. Killmore and E.V. Pereloma: Mater. Sci. Eng. A, 2014, vol. 607, pp. 226-35.

A.J. Ardell: Metall. Trans. A, 1985, vol. 16A, pp. 2131-65.

E.V. Pereloma, A. Shekhter, M.K. Miller and S.P. Ringer: Acta Mater., 2004, vol. 52, pp. 5589–5602.

E.V. Pereloma, R.A. Stohr, M.K. Miller and S.P. Ringer: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 3069-75.

S.P. Ringer: Mater. Sci. Forum, 2006, vol. 519-521, pp. 25-34.

Acknowledgments

Grateful thanks are expressed to Dr. Gianluigi Botton, Dr. Glynis de Silveira, and Dr. Andreas Korinek for their help on TEM-EELs characterization of the steel sample, and to Dr. Lijun Wang for help on steel sample preparation. The funding support from CBMM, Brazil is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 14, 2016.

Appendices

Appendix A

where V MN is the volume of precipitated MN and V Fe is the volume of ferrite. The volume V of a given mole X of a material can be calculated as

where X is mole of the material; N a is the Avogadro’s number; N u is the number of atoms per unit cell of the materials (N u is 4 for MN precipitate and austenite Fe, and 2 for ferritic Fe, respectively); V u is the volume of the unit cell of the material and cube of the lattice parameter for MN. (Lattice parameter: 0.359 nm for austenite Fe, 0.286 nm for ferrite Fe, 0.425 nm for TiN, 0.443 nm for NbC)

where m is mass of a material and P is the atomic weight of the material.

For assumption of stoichiometric ratio between M and N, X M = X N.

Therefore, volume fraction of MN can be calculated by substituting all values in Eq. [A.1].

Appendix B

The Ashby–Orowan equation can be expressed as

where M is the Taylor factor, taken as 2.75; υ is the Poisson’s ratio, taken as 0.293; G is the Shear modulus of low carbon steel, 79,600 MPa; b is the Burger’s vector, 0.248 nm; λ is the inter-spacing of particles on slip plane.

where d is the mean diameter of particle.

For a given volume fraction, f, and precipitate diameter, d, the increment in yield strength can be calculated by substituting all values in Eq. [B.2].

Appendix C

The order strengthening from Nb(C,N) atom clusters can be calculated from

where M = 2 is the matrix orientation factor; b = 0.248 nm is Burger’s vector; γ is matrix-cluster interface energy, which is assumed to be 1 J m−2; f is the cluster volume fraction.

For predicted cluster volume fraction of 0.00233 from atom probe data analysis, order strengthening increment is calculated to be 170 MPa.

Rights and permissions

About this article

Cite this article

Ma, X., Langelier, B., Gault, B. et al. Effect of Nb Addition to Ti-Bearing Super Martensitic Stainless Steel on Control of Austenite Grain Size and Strengthening. Metall Mater Trans A 48, 2460–2471 (2017). https://doi.org/10.1007/s11661-017-4036-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4036-7