Abstract

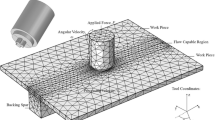

Joining thick sections of aluminum alloys by friction stir welding (FSW) in a single pass needs to overcome many challenges before it comes to full-scale industrial use. Important parameters controlling the structure-properties relationships both across weld cross-section and through thickness direction were investigated through mechanical testing, electron backscatter diffraction technique, transmission electron microscopy, and occurrence of serrated plastic flow. The evolution of the properties in the weld cross-section shows that the presence of undissolved and fragmented Al\(_6\)MnFe particles cause discrepancies in establishing the Hall-Petch relationship, and derive the strengthening from the Orowan strengthening mechanism. A ‘stop action’ friction stir weld has been prepared to understand the role of geometrical features of the tool probe in the development of the final microstructure after complete weld. Sectioning through the ‘stop action’ weld with the probe in situ displays the individual effect of thread and flat on the grain structure formation. The material at the thread surface experiences more severe deformation than the material at flat surface. Both the high-angle boundaries and mean grain size are found to be higher at the thread surface. The strain hardening capacity, stress serration amplitude, and frequency are observed to be higher in the stir zone than other weld regions.

Similar content being viewed by others

References

G. Cam, S. Mistikoglu, J. Mater Eng. Perform. 23, 1936–1953 (2014)

J.G. Perrett, J. Martin, P.L. Threadgil and M.M.Z. Ahmed: Proceedings of the 6th World Congress, Al., 2007. vol. 2000, pp. 13–17

E. Dalder, J.W. Pastrnak, J. Engel, R.S. Forrest, E. Kokko, K. McTernan, D. Waldron, Weld. J. 87(4), 40–44 (2008)

B. Thompson, K. Doherty, C. Niese, M. Eff, T. Stotler, Z. Pramann, J. Seaman, R. Spencer, P. White: 9th International Symposium on Friction Stir Welding (9ISFSW), 15–17 May 2012

A. Kaur, C. Ribton, W. Balachandaran, J. Mater. Process. Technol. 221, 225–232 (2015)

P. Bourges, R. Blondeau, A. Ducrot, J. Binard, Int. J. Pres. Ves. Pip. 32, 355–387 (1988)

H. Schultz, Electron Beam Welding (Elsevier, Oxford, 1994)

S. Sarafan, P. Wanjara, H. Champliaud, D. Thibault, Int. J. Adv. Manuf. Technol. 78, 1523–1525 (2015)

P.L. Threadgill, A.J. Leonard, H.R. Shercliff, P.J. Withers, Int. Mater. Rev. 54(2), 49–93 (2009)

R.S. Mishra, Z.Y. Ma, Mater. Sci. Eng. R. 50, 1–78 (2005)

M. Imam, K. Biswas, V. Racherla, Mater. Des. 52, 730–739 (2013)

H.J. Liu, H. Fujii, M. Maeda, K. Nogi, J. Mater. Process. Technol. 142, 692–696 (2003)

M. Imam, R. Ueji, H. Fujii, Mater. Sci. Eng. A 636, 24–34 (2015)

M. Imam, R. Ueji, H. Fujii, J. Mater. Process. Technol. 230, 62–71 (2016)

M. Imam, V. Racherla, K. Biswas, Mater. Des. 64, 675–686 (2014)

R. Nandan, T. Debroy, H.K.D.H. Bhadeshia, Prog. Mater. Sci. 53, 980–1023 (2008)

X. He, F. Gu, A. Ball, Prog. Mater. Sci. 65, 1–66 (2014)

P. Upadhyay, A. Reynolds, Metall. Mater. Trans. A 45A, 2091–2100 (2014)

P. Upadhyay, A. Reynolds, J. Miner. Met. Mater. Soc. (TMS) 67(5), 1022–1031 (2015)

B. Malard, F. De Geuser, A. Deschamps, Acta Mater. 101, 90–100 (2015)

S. Nimer, J. Wolk, M. Zupan, Acta Mater. 61, 3050–3059 (2013)

S. Toros, F. Ozturk, I. Kacar, J. Mater. Process. Technol. 207, 1–12 (2008)

M.P. Liu, H.J. Roven, M.Y. Murashkin, R.Z. Valiev, A. Kilmametov, Z. Zhang, Y. Yu, J. Mater. Sci. 48, 4681–4688 (2013)

T.D. Topping, B. Ahn, Y. Li, S.R. Nutt, E.J. Lavernia, Metall. Mater. Trans. A 43A, 505–519 (2012)

D.S. D’Antuono, J. Gaies, W. Golumbfskie, M.L. Taheri, Scr. Mater. 76, 81–84 (2014)

E.L. Huskins, B. Cao, K.T. Ramesh, Mater. Sci. Eng. A 527, 1292–1298 (2010)

Y.S. Sato, M. Urata, H. Kokawa, K. Ikeda, Mater. Sci Eng. A 354, 298–305 (2003)

L.-E. Svensson, L. Karlsson, H. Larsson, B. Karlsson, M. Fazzini, J. Karlsson, Sci. Technol. Weld. Join. 5(5), 285–296 (2000)

Y.S. Sato, S.H.C. Park, H. Kokawa, Metall. Mater. Trans. A 32A, 3033–3042 (2001)

M.M. Attallah, C.L. Davis, M. Strangwood, J. Mater. Sci. 42, 7299–7306 (2007)

P.A. Colegrove, H.R. Shercliff, Sci. Technol. Weld. Join. 9(4), 352–361 (2004)

Y.S. Sato, H. Kokawa, K. Ikeda, M. Enomoto, S. Jogan, T. Hashimoto, Metall. Mater. Trans. A 32A, 941–948 (2001)

R.W. Fonda, J.F. Bingert, K.J. Colligan, Scr. Mater. 51, 243–248 (2004)

R.W. Fonda, J.F. Bingert, Scr. Mater. 57, 1052–1055 (2007)

R.W. Fonda, K.E. Knipling, Sci. Technol. Weld. Join. 16(4), 288–294 (2011)

H.B. McShane, C.P. Lee, T. Sheppard, Mater. Sci. Technol. 6(5), 428–440 (1990)

H. Izadi, R. Sandstrom, A.P. Gerlich, Metall. Mater. Trans. A 45A, 5635–5644 (2014)

J.R. Cahoon, W.H. Broughton, A.R. Kutzak, Metall. Trans. 2, 1979–1983 (1971)

P. Zhang, S.X. Li, Z.F. Zhang, Mater. Sci. Eng. A 529, 62–73 (2011)

H. Li, F. Ebrahimi, Mater. Sci. Eng. A 347, 93–101 (2003)

W.J. Arbegast, Scr. Mater. 58, 372–376 (2008)

A. Gholinia, F.J. Humphreys, P.B. Prangnell, Acta Mater. 50, 4461–4476 (2002)

K.A.A. Hassan, P.B. Prangnell, A.F. Norman, D.A. Price, S.W. Williams, Sci. Technol. Weld. Join. 8(4), 257–268 (2003)

T.R. McNelley, S. Swaminathan, J.Q. Su, Scr. Mater. 58, 349–354 (2008)

H.J. Mcqueen, E. Evangelista, J. Bowles, G. Crawford, Metall. Sci. 18, 395–402 (1984)

K.E. Tello, A.P. Gerlich, P.F. Mendez, Sci. Technol. Weld. Join. 15(3), 260–266 (2013)

C.G. Rhodes, M.W. Mahoney, W.H. Bingel, M. Calabrese, Scr. Mater. 48, 1451–1455 (2003)

M. Furukawa, Z. Horita, M. Nemoto, R.Z. Valiev, T.G. Langdon, Acta Mater. 44(11), 4619–4629 (1996)

N. Hansen, Scr. Mater. 51, 801–806 (2004)

Z.Y. Ma, Metall. Mater. Trans. A 39A, 642–658 (2008)

Ø. Frigaard, Ø. Grong and O. Midling: Mater. Trans. A, 2000, vol. 32A, pp. 1189-1200

Y.S. Sato, H. Kokawa, Metall. Mater. Trans. A 32A, 3023–3031 (2001)

Y.S. Sato, H. Kokawa, M. Enomoto, S. Jogan, Metall. Mater. Trans. A 30A, 2429–2437 (1999)

M. Imam, V. Racherla, K. Biswas, Int. J. Adv. Manuf. Technol. 77(9–12), 2181–2195 (2015)

H. Hasegawa, S. Komura, A. Utsunomiya, Z. Horita, M. Furukawa, M. Nemoto, T.G. Langdon, Mater. Sci. Eng. A 265, 188–196 (1999)

P. Bazarnik, Y. Huang, M. Lewandowska, T.G. Langdon, Mater. Sci. Eng. A 626, 9–15 (2015)

W.F. Xu, J.H. Liu, D.L. Chen, G.H. Luan, J.S. Yao, Mater. Sci. Eng. A 548, 89–98 (2012)

S.Q. Wang, J.H. Liu, D.L. Chen, Mater. Des. 56, 174–184 (2014)

N. Afrin, D.L. Chen, X. Cao, M. Jahazi, Scr. Mater. 57, 1004–1007 (2007)

Ø. Ryen, O. Nijs, E. Sjolander, B. Holmedal, H. Ekstrom and E. Nes: Metal. Mater. Trans. A, 2006, vol. 37A, 1999-2006

H. Halim, D.S. Wilkinson, M. Niewczas, Acta Mater. 55, 4151–4160 (2007)

F.B. Klose, J. Weidenmüller, A. Ziegenbein, P. Hähner, H. Neuhäuser: Philos. Mag., 2004, vol. 84, pp. 467-480

S.L. Xia, M. Mia, J.X. Zhang, W.X. Wang, W.C. Liu, Mater. Sci. Eng. A 609, 168–176 (2014)

S.P. Joshi, C. Eberl, B. Cao, K.T. Ramesh, K.J. Hemker, Exp. Mech. 49, 207–18 (2009)

M. Komarasamy, R.S. Mishra, Mater. Sci. Eng. A 616, 189–195 (2014)

Acknowledgments

This work was supported by the JSOL Corporation, Engineering Technology Division. The authors would like to thank the staff of the welding workshop of the Joining and Welding Research Institute of Osaka University for their cooperation and support. The authors also thank the students of Fujii laboratory for their cooperation and support in carrying out the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 9, 2016.

Rights and permissions

About this article

Cite this article

Imam, M., Sun, Y., Fujii, H. et al. Microstructural Characteristics and Mechanical Properties of Friction Stir Welded Thick 5083 Aluminum Alloy. Metall Mater Trans A 48, 208–229 (2017). https://doi.org/10.1007/s11661-016-3819-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3819-6