Abstract

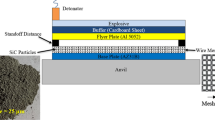

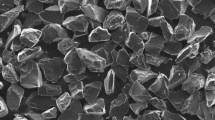

The present investigation shows that alternate to the ceramic particles, hard metallic particles can be used as reinforcement in an aluminum matrix to achieve a good strength–ductility combination in a composite. Titanium particles were incorporated into aluminum by friction stir processing (FSP) to process an Al-Ti particulate composite. FSP led to uniform distribution of the particles in the stir zone without any particle–matrix reaction, thereby retaining the particles in their elemental state. Fracture and twinning of the Ti particles with different frequency of occurrence on the advancing and retreating sides of the stir zone was observed. Twinning of the particles was studied by focused ion beam-assisted transmission electron microscopy. The processed Al-Ti composite exhibited a significant improvement in strength and also retained appreciable amount of ductility. The thermal stability of the fine-grained structure against abnormal grain growth (AGG) was improved by the Ti particles. The AGG in the Al-Ti composite occurred at 713 K (440 °C) compared to 673 K (400 °C) in the unreinforced aluminum processed under the same conditions. On the other hand, the particle–matrix reaction occurred only at 823 K (550 °C), and hence the Ti particles were thermally more stable compared to the matrix grain structure.

Similar content being viewed by others

References

T.W. Clyne and P.J. Withers: An introduction to metal matrix composites, 1st Ed., Cambridge University Press, Cambridge, 1993.

B. Ralph, H.C. Yuen and W.B. Lee: J. Mater. Process. Technol., 1997, vol. 63, pp. 339-53.

J.V. Wood, P. Davies and J.L.F. Kellie: Mater. Sci. Technol., 1993, vol. 9 pp. 833-40.

B.F. Luan, N. Hansen, A. Godfrey, G.H. Wu and Q. Liu: Mater. Des., 2011, vol. 32, pp. 3810-17.

S.J. Hong, H.M. Kim, D. Huh, C. Suryanarayana and B.S. Chun: Mater. Sci. Eng. A, 2003, vol. 347, pp. 198-04.

R.J. Arsenault and N. Shi: Mater. Sci. Eng., 1986, vol. 81, pp. 175-87.

K.B. Lee, H.S. Sim, S.Y. Cho and H. Kwon: Mater. Sci. Eng. A, 2001, vol. 302, pp. 227-34.

J.J. Lewandowski and C. Liu: Mater. Sci. Eng. A, 1989, vol. 107, pp. 241-55.

Z. Wang, M. Song, C. Sun, D. Xiao and Y. He: Mater. Sci. Eng. A, 2010, vol. 527, pp. 6537-42.

S.C. Deevi and V.K. Sikka: Intermetallics, 1996, vol. 4, pp. 357-75.

W.Y. Yang and G.C. Weatherly: J. Mater. Sci., 1996, vol. 31, pp. 3707-13.

J.C. Rawers and H.E. Maupin: J. Mater. Sci. Lett., 1993, vol. 12, pp. 637-39.

D. Özyürek, S. Tekeli, T. Tuncay and R. Yilmaz: Powder Metall. Met. Ceram., 2012, vol. 51, pp. 491-95.

M. Sujata, S. Bhargava and S. Sangal: Iron Steel Inst. Jpn., 1996, vol. 36, pp. 255-62.

S. Mousheng, Z. Mengxian, H. Bin, Z. Shuguang and L. Jianguo: Rare Met. Mater. Eng., 2008, vol. 37, pp. 1570-74.

S.K. Thakur and M. Gupta: Composites Part A, 2007, vol. 38, pp. 1010-18.

D. Yang, P. Cizek, P. Hodgsona and C. Wen: Scripta Mater., 2010, vol. 62, pp. 321-24.

T. Marr, J. Freudenberger, D. Seifert, H. Klauβ, J. Romberg, I. Okulov, J. Scharnweber, A. Eschke, C.G. Oertel, W. Skrotzki, U. Kühn, J. Eckert and L. Schultz: Metals, 2011, vol. 1, pp. 79-97.

C.Y. Liu, B. Zhang, P.F. Yu, R. Jing, M.Z. Ma and R.P. Liu: Mater. Sci. Eng. A, 2013, vol. 580, pp. 36-40.

R.S. Mishra, M.W. Mahoney, S.X. McFadden, N.A. Mara and A.K. Mukherjee, High strain rate superplasticity in a friction stir processed 7075 Al alloy: Scripta Mater., 2000, vol. 42, pp. 163-68.

R.S. Mishra and Z.Y. Ma: Mater. Sci. Eng. R, 2005, vol. 50, pp. 1-78.

C.I. Chang, X. H. Du and J.C. Huang: Scripta Mater., 2007, vol. 57, pp. 209-12.

J.Q. Su, T.W. Nelson and C.J. Sterling: Scripta Mater., 2005, vol. 52, pp. 135-40.

J.Q. Su, T.W. Nelson and C.J. Sterling: J. Mater. Res., 2003, vol. 18, pp. 1757-60.

Z.Y. Ma: Metall. Mater. Trans. A, 2008, vol. 39, pp. 642-58.

C.J. Hsu, C.Y. Chang, P.W. Kao, N.J. Ho and C.P. Chang: Acta Mater., 2006, vol. 54, pp. 5241-49.

R.S. Mishra, Z.Y. Ma and I. Charit: Mater. Sci. Eng. A, 2003, vol. 341, pp. 307-10

C.F. Chen, P.W. Kao, L.W. Chang and N.J. Ho: Metall. Mater. Trans. A, 2009, vol. 41, pp. 513-22.

M.S. Khorrami, M. Kazeminezhad and A.H. Kokabi: Metall. Mater. Trans. A, 2015, vol. 46, pp. 2021-34.

H.S. Arora, H. Singh and B.K. Dhindaw: Int. J. Adv. Manuf. Technol, 2012, vol. 61, pp. 1043-55.

D. Yadav and R. Bauri: Mater. Lett., 2010, vol. 64, pp. 664-67.

D. Yadav and R. Bauri: Mater. Sci. Tech., 2015, vol. 31, pp. 494-500.

T.B. Massalski and H. Okamoto: Binary alloy phase diagrams. Materials Park (OH), ASM International, 1993.

J.C. Schuster and M. Palm: J. Phase Equilib. Diffus., 2006, vol. 27, pp. 255-77.

Q. Zhang, B.L. Xiao and Z.Y. Ma: Mater. Chem. Phys., 2013, vol. 139, pp. 596-602.

W.J. Arbegast, and P.J. Hartley: Proceedings of the Fifth International Conference on Trends in Welding Research, Pine Mountain, USA (1998) 541.

S.K. Das and L.A. Davis: Mater. Sci. Eng., 1988, vol. 98, pp. 1-12.

J.W. Christian and S. Mahajan: Prog. Mater. Sci., 1995, vol. 39, pp. 1-157.

M.H. Yoo: Metall. Mater. Trans. A, 1981, vol. 12, pp. 409-418.

S.R. Kalidindi, A.A. Salem and R.D. Doherty: Adv. Eng. Mater., 2003, vol. 5, pp. 229-32.

N.E. Paton and W.A. Backofen: Metall. Mater. Trans. B, 1970, vol. 1, pp. 2839-47.

T.U. Seidel and A.P. Reynolds: Metall. Mater. Trans. A, 2001, vol. 32, pp. 2879-84.

S. Agarwal, C.L. Briant, L.G. Hector Jr. and Y.L. Chen: J. Mater. Eng. Perform., 2007, vol. 16, pp. 391-403.

J.Q. Su, T.W. Nelson and C.J. Sterling: Mater. Sci. Eng. A, 2005, vol. 405, pp. 277-86.

P.B. Prangnell and C.P. Heason: Acta Mater., 2005, vol. 53, pp. 3179-92.

C.G. Rhodes, M.W. Mahoney, W.H. Bingel and C. Calabrese: Scripta Mater., 2003, vol. 48, pp. 1451-55.

J.Q. Su, T.W. Nelson and C.J. Sterling: Phil. Mag., 2006, vol. 86, pp. 1-24.

R. Bauri, D. Yadav, C.N.S. Kumar and B. Balaji: Mater. Sci. Eng. A, 2015, vol. 620, pp. 67-75.

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd eds., Elsevier, Oxford, 2004, pp. 448, 368.

E.A. Brandes and G.B. Brook (Eds.): Smithell’s Metals Reference Book, 7th Ed., Butterworth and Heinemann, Oxford, 1992, pp. 14.

D. Yadav and R. Bauri: Mater. Sci. Eng. A 2011, vol. 528, pp.1326-1333.

D. Yadav and R. Bauri: J. Mater. Eng. Perform., 2015, vol. 24, pp. 1116-1124.

I. Charit and R.S. Mishra: Scripta Mater., 2008, vol. 58, pp. 367-71.

S. Mironov, K. Masaki, Y.S. Sato and H. Kokawa: Metall. Mater. Trans. A, 2013, vol. 44, pp. 1153-57.

E.M. Taleff and N.A. Pedrazas: Science, 2013, vol. 341, pp. 1461-62.

T. Omori, T. Kusama, S. Kawata, I. Ohnuma, Y.Sutou, Y. Araki, K. Ishida and R. Kainuma: Science, 2013, vol. 341, pp. 1500-02.

D.J. Srolovitz, G.S. Grest and M.P. Anderson: Acta Metall., 1985, vol. 33, pp. 2233-47.

Y. Morisada, H. Fujii, T. Nagaoka and M. Fukusumi: Mater. Sci. Eng. A, 2006, vol. 433, pp. 50-54.

T. Marr, J. Freudenberger, A. Kauffmann, J. Romberg, I. Okulov, R. Petters, J. Scharnweber, A. Eschke, C.G. Oertel, U. Kühn, J. Eckert, W. Skrotzki and L. Schultz: Metals, 2013, vol. 3, pp. 188-201.

L. Xu, Y.Y. Cui, Y.L. Hao and R. Yang: Mater. Sci. Eng. A, 2006, vol. 435-436, pp. 638-47.

D. Yang, P. Hodgson and C. Wen: Intermetallics, 2009, vol. 17, pp. 727-32.

A.D. Smigelskas and E.O. Kirkendall: Tran. Am. Inst. Min., Metall. Pet. Eng., 1947, vol. 171, pp. 130-42.

Acknowledgments

The authors would like to thank the Faculty at the Materials Joining Laboratory, IIT Madras, for providing access to the NRB-supported FSP facility. The authors thank T. Sturm for experimental assistance with the FIB lift-out.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 10, 2015.

Rights and permissions

About this article

Cite this article

Yadav, D., Bauri, R., Kauffmann, A. et al. Al-Ti Particulate Composite: Processing and Studies on Particle Twinning, Microstructure, and Thermal Stability. Metall Mater Trans A 47, 4226–4238 (2016). https://doi.org/10.1007/s11661-016-3597-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3597-1