Abstract

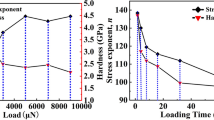

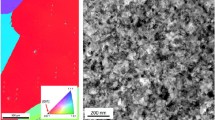

Nanoindentation creep behavior was studied on a coarse-grained Al0.3CoCrFeNi high-entropy alloy with a single face-centered cubic structure. The effects of the indentation size and loading rate on creep behavior were investigated. The experimental results show that the hardness, creep depth, creep strain rate, and stress exponent are all dependent on the holding load and loading rate. The creep behavior shows a remarkable indentation size effect at different maximum indentation loads. The dominant creep mechanism is dislocation creep at high indentation loads and self-diffusion at low indentation loads. An obvious loading rate sensitivity of creep behavior is found under different loading rates for the alloy. A high loading rate can lead to a high strain gradient, and numerous dislocations emerge and entangle together. Then during the holding time, a large creep deformation characteristic with a high stress exponent will happen.

Similar content being viewed by others

References

J. W. Yeh, S. K. Chen, S. J. Lin, J. Y. Gan, T. S. Chin, T. T. Shun, C. H. Tsau, and S. Y. Chang: Advanced Engineering Materials, 2004, vol. 6, pp. 299-303.

B. Cantor, I. T. H. Chang, P. Knight, and A. J. B. Vincent: Materials Science and Engineering: A, 2004, vol. 375, pp. 213-218.

Y. Zhang, T. T. Zuo, Z. Tang, C. G. Michael, K. A. Dahmen, P. K. Liaw, and Z. P. Lu: Progress in Materials Science, 2014, vol. 61, pp. 1-93.

K. Zhao, X. X. Xia, H. Y. Bai, D. Q. Zhao, and W. H. Wang: Appl Phys Lett, 2011, vol. 98, pp. 141913.

S. Guo, Q. Hu, C. Ng, and C. T. Liu: Intermetallics, 2013, vol. 41, pp. 96-103.

J.Y. He, H. Wang, H. L. Huang, X. D. Xu, M. W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, and Z. P. Lu: Acta Materialia, 2016, vol. 102, pp. 187-196.

B. Gludovatz, A. Hohenwarter, D. Catoor, E. H. Chang, E. P. George, and R. O. Ritchie: Science, 2014, vol. 345, pp.1153-1158.

O. N. Senkov, G. B. Wilks, D. B. Miracle, C. P. Chuang, and P. K. Liaw: Intermetallics, 2010, vol. 18(9), pp. 1758-1765.

Z. Tang, T. Yuan, C. W. Tsai, J. W. Yeh, C. D. Lundin, and P. K. Liaw: Acta Materialia, 2015, vol. 99, pp. 247-258.

M. H. Chuang, M. H. Tsai, W. R. Wang, S. J. Lin, and J. W. Yeh: Acta Mater, 2011, vol. 59, pp. 6308-6317.

Y. Zhang, Y. J. Zhou, J. P. Lin, G. L. Chen, and P. K. Liaw: Advanced Engineering Materials, 2008, vol. 10(6), pp. 534-538.

Y. Zhang, T.T. Zuo, Y.Q. Cheng, and P. K. Liaw: Scientific Reports, 2013, vol. 3.

M. A. Hemphill, T. Yuan, G. Y. Wang, J. W. Yeh, C. W. Tsai, A. Chuang, and P. K. Liaw: Acta Materialia, 2012, vol. 60, pp. 5723-5734.

M. Seifi, D. Li, Z. Yong, P. K. Liaw, and J. J. Lewandowski: JOM, 2015, vol. 67, pp. 2288-2295.

Y. F. Kao, T. J. Chen, S. K. Chen, and J. W. Yeh: Journal of Alloys and Compounds, 2009, vol. 488, pp. 57-64.

W. R. Wang, W. L. Wang, and J. W. Yeh: Journal of Alloys and Compounds, 2014, vol. 589, pp. 143-152.

N. D. Stepanov, D. G. Shaysultanov, G. A. Salishchev, M. A. Tikhonovsky, E. E. Oleynik, A. S. Tortika, and O. N. Senkov,: Journal of Alloys and Compounds, 2015, vol. 628, pp. 170-185.

W. H. Liu, J. Y. He, H. L. Huang, H. Wang, Z. P. Lu, and C. T. Liu: Intermetallics, 2015, vol. 60, pp. 1-8.

Y. J. Zhou, Y. Zhang, Y. L. Wang, and G. L. Chen: Appl. Phys. Lett, 2007, vol. 90, pp. 181904.

C.Y. Hsu, C.C. Juan, W.R. Wang, T.S. Sheu, J.W. Yeh, and S.K. Chen (2011) Mater. Sci. Eng. A, 528:3581-3588.

P. Koželj, S. Vrtnik, A. Jelen, S. Jazbec, Z. Jagličić, S. Maiti, M. Feuerbacher, W. Steurer, and J. Dolinšek: Phys. Rev. Lett, 2014, vol. 113, pp. 107001.

S. Q. Wang: AIP Adv, 2013, vol. 3(10), pp. 842-852.

Y. F. Kao, S. K. Chen, J. H. Sheu, J. T. Lin, W. E. Lin, J. W. Yeh, S. J. Lin, T. H. Liou, and C. W. Wang: Int. J. Hydrogen Energy, 2010, vol. 35, pp. 9046-9059.

V. Braic, M. Balaceanu, M. Braic, A. Viadescu, S. Panseri, and A. Russo (2012) J. Mechl Behav, Biomed. Mater, 10: 197-205.

Z. H. Cao, P. Y. Li, H. M. Lu, Y. L. Huang, Y. C. Zhou, and X. K. Meng: Scripta Materialia, 2009, vol. 60, pp. 415-418.

Y. J. Huang, J. Shen, Y. L. Chiu, J. J. J. Chen, and J. F. Sun: Intermetallics, 2009, vol. 17, pp. 190-194.

Z. S. Ma, S. G. Long, Y. Pan, Y. C. Zhou: J Mater Sci, 2008, vol. 43, pp. 5952-5955.

W.C. Oliver, G.M. Pharr: J. Mater. Res, 1992, vol. 7, pp. 1564-1583.

C. L. Wang, M. Zhang, and T. G. Nieh: J. Phys. D: Appl. Phys, 2009, vol. 42, pp. 115405.

W. B. Li, J. L. Henshall, R. M. Hooper, and K. E. Easterling: Acta metallurgica et materialia, 1991, vol. 39, pp. 3099-3110.

P. F. Yu, S. D. Feng, G. S. Xu, X. L. Guo, Y. Y. Wang, W. Zhao, L. Qi, G. Li, P. K. Liaw, and R. P. Liu: Scripta Materialia, 2014, vol. 90-91, pp. 45-48.

Z. S. Ma, S. G. Long, Y. C. Zhou, and Y. Pan: Scripta Materialia, 2008, vol. 59, pp. 195-198.

F. Wang, P. Huang, and K. W. Xu: Appl. Phys. Lett., 2007, vol. 90, pp. 161921.

H. Li, A. H. W. Ngan: J. Mater. Res, 2004, vol. 19(2), pp. 513-522.

S. R. Jian, G. J. Chen, and J. Y. Juang: Current Opinion in Solid State & Materials Science, 2010, vol. 14, pp. 69-74.

S. J. Bull: J. Phys. D: Appl. Phys, 2005, vol. 38, pp. 393-413.

J. E. Bradby, S. O. Kucheyev, J. S. Williams, J. Wong-Leung, M. V. Swain, P. Munroe, G. Li, and M. R. Phillips: Appl. Phys. Lett, 2002, vol. 80, pp. 383-385.

S. R. Jian: Journal of Alloys and Compounds, 2015, vol. 644, pp. 54-58.

T. T. Shun, C. H. Hung, and C. F. Lee: Journal of Alloys and Compounds. 2010, vol. 493, pp. 105-109.

Acknowledgments

The research was supported by the National Science Foundation of China (Grant No. 51121061/51171163). Gong Li would like to acknowledge the Specialized Research Fund for the Doctoral Program of Higher Education (Grant No. 20131333110019). Peter K. Liaw would like to acknowledge the U.S. National Science Foundation Project (CMMI-1100080), the U.S. Army Research Office Project (W911NF-13-1-0438) with the program manager, S. N. Mathaudhu, D. M. Stepp, and C. Coohes, and the DOE, Office of Fossil Energy, National Energy Technology Laboratory (DE-FE-0008855, DE-FE-0011194, and DE-FE-0024054), with Mr. V. Cedro, Mr. R. Dunst, and Dr. J. Mullen as program managers, respectively.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted December 29, 2015.

Rights and permissions

About this article

Cite this article

Zhang, L., Yu, P., Cheng, H. et al. Nanoindentation Creep Behavior of an Al0.3CoCrFeNi High-Entropy Alloy. Metall Mater Trans A 47, 5871–5875 (2016). https://doi.org/10.1007/s11661-016-3469-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3469-8