Abstract

The tearing resistance, dJ/da, of conventional 2.25Cr-1Mo steels and a V-bearing steel (2.25Cr-1Mo-0.3V steel) with internal hydrogen was measured using the effective offset potential drop method. Internal hydrogen refers to test specimens that are precharged (thermally charged) prior to testing. In general, Cr-Mo steels, used widely in the refining and petrochemical industries, are susceptible to temper embrittlement. However, very few studies have dealt with the effects of hydrogen and temper embrittlement on the tearing resistance. Test specimens were prepared by subjecting them to normalizing, tempering, and post-weld heat treatments that simulated actual conditions. Some specimens were embrittled by step cooling. Hydrogen substantially reduced dJ/da for all samples except for that for the V-bearing steel, and temper embrittlement caused additional adverse effects on dJ/da for samples with internal hydrogen for which the temper embrittlement parameter, i.e., the J-factor, was large.

Similar content being viewed by others

Abbreviations

- \( a_{(i)} \) :

-

Current crack length

- \( a_{0} \) :

-

Initial fatigue precrack length

- \( A \) :

-

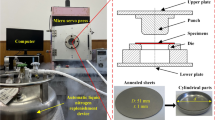

Plane area due to material removal for machining integral knife edges shown in Figure 3

- \( A_{0} \) :

-

Plane area of compact tension (CT) specimen shown in Figure 3

- \( b_{(i)} \) :

-

Current uncracked ligament \( = W - a_{(i)} \)

- B :

-

Specimen thickness

- \( B_{N} \) :

-

Specimen net thickness

- \( C(t,\,x,\,y) \) :

-

Hydrogen content at an arbitrary location at time t

- \( C_{0} \) :

-

Initial hydrogen content

- \( \bar{C} \) :

-

Average hydrogen content in an uncracked region of a CT specimen

- \( \bar{C}^{A} \) :

-

Area-averaged hydrogen content in an uncracked region of a CT specimen

- \( D \) :

-

Diffusivity of hydrogen

- \( E \) :

-

Young’s modulus

- 2H :

-

Specimen height

- \( J_{{a = a_{0} }} \) :

-

J-integral using an initial fatigue precrack length \( a_{0} \)

- \( J_{0} \) :

-

Threshold fracture toughness, \( J_{{a = a_{0} }} \), at the onset of subcritical crack growth

- \( J_{{ ( {\text{i)}}}} \) :

-

Current value of J-integral using the current crack length \( a_{(i)} \)

- \( J_{\text{el(i)}} \, \) :

-

Current elastic component of \( J_{{ ( {\text{i)}}}} \)

- \( J_{\text{pl(i)}} \, \) :

-

Current plastic component of \( J_{{ ( {\text{i)}}}} \)

- JPVRC:

-

Japan Pressure Vessel Research Council

- J-factor:

-

\( ( {\text{Pct}}\;{\text{Si}} + {\text{Pct}}\;{\text{Mn)}} \times ( {\text{Pct}}\;{\text{P}} + {\text{Pct}}\;{\text{Sn)}} \times 10^{4} \)

- \( t \) :

-

Time (hour)

- \( V \) :

-

Measured dc-potential drop (PD) voltage

- \( V_{r} \) :

-

Reference crack dc-voltage

- \( V_{\text{eff}} \) :

-

Effective dc-potential drop voltage

- \( V_{{{\text{eff}},r}} \) :

-

Effective reference crack dc-voltage

- \( W \) :

-

Specimen width

- \( P_{(i)} \) :

-

Current load

- \( Y \) :

-

Lead-out distance

- \( \beta \) :

-

Arbitrary constant to Make the slope of the \( \xi \) vs \( J_{{a = a_{0} }} \) plot equal to zero

- \( \nu \) :

-

Poisson’s ratio

- \( v_{i} \) :

-

Current load-line displacement

- \( v_{{{\text{pl}}(i)}} \) :

-

Plastic part of the load-line displacement

- \( \xi \) :

-

Offset dc-potential drop

- 1/2T-CT:

-

Half size of 1T-CT specimen

- 1T-CT(1/2):

-

Half size of 1T-CT specimen, except for the 25.4-mm-thick sample

References

C. A. Zapffe, and C. E. Sims: Metals & Alloys, 1940, vol. 12, pp.145-151.

A. R. Troiano: Transactions of the ASM, 1960, vol. 52, pp.54-80.

D. G. Weslake: Transactions of the ASM, 1969, vol. 62, pp.1000-1006.

R. A. Oriani and E. H. Josephic: Acta Metallurgica, 1974, vol. 22, pp.1065-1074.

H. K. Birnbaum, P. Sofronis (1994) Mater. Sci. Eng., 176:191-202.

R P Gangloff and B P Somerday: Gaseous Hydrogen Embrittlement of Materials in Energy Technologies - The Problem, its characterisation and Effects on Particular Alloy Classes, Woodhead Publishing, Cambridge UK, 2012.

Y. Tanaka, S. Aihara, S. Konosu, K. Hayashi, M. Yuga, H. Yamamoto, N. Ohtsuka, and H. Mimura: Proceedings of ASME, 2006, Paper No. PVP2006-ICPVT11-93360.

H. Shimazu, S. Konosu, Y. Tanaka, M. Yuga, H. Yamamoto, N. Ohtsuka (2013) ASME J. Press. Vessel Technol. 135(2):1–7.

P.C. Paris, H. Tada, A. Zahoor, and H. Ernst: ASTM STP668, 1979, pp. 251–65.

ASTM E1820-11: Annual book of ASTM standards, “Standard Test Method for Measurement of Fracture Toughness,” 2011.

ASTM E647-11: Annual book of ASTM standards, “Standard Test Method for Measurement of Fatigue Crack Growth Rates,” 2011.

ASTM E1737-96: Annual book of ASTM standards, “Standard Test Method for J-Integral Characterization of Fracture Toughness,” 1996.

M. A. Hicks and A. C. Pickard: Int. Journal of Fracture, 1982, vol. 20, pp.91-101.

T. Sakai, K. Asami, M. Katsumata, H. Takada and O. Tanaka: in Proceedings of 1st. Int. Conf. on Current Solution to Hydrogen Problems in Steels, C.G. Interrant and G.M. Pressouyre, eds., American Society for Metals, Metals Park, 1982, pp. 340–48.

E. C. Horning, M. G. Horning, D. I. Carroll, I. Dzidic, and R. N. Stillwell, Analytical Chemistry, 1973, vol. 45, no. 6, pp.936-943.

W.G. Clark, Jr., and L.D. Landes: ASTM STP610, 1972, pp. 108–27.

T. Iwadate, T. Nomura and J. Watanabe, Corrosion, 1988, vol. 44, no. 2, pp.103-112.

S. Pillot and L. Coudreuse: Gaseous Hydrogen Embrittlement of Materials in Energy Technologies—The Problem, Its Characterisation and Effects on Particular Alloy Classes, R.P. Gangloff and B.P. Somerday, eds., Woodhead Publishing, Cambridge, U.K., 2012, pp. 51–93.

G.A. Young, Jr., E. Richey, and D.S. Morton: Gaseous Hydrogen Embrittlement of Materials in Energy Technologies—The Problem, Its Characterisation and Effects on Particular Alloy Classes, R.P. Gangloff and B.P. Somerday, eds., Woodhead Publishing, Cambridge, U.K., 2012, pp. 149–76.

H. H. Johnson: Material Research and Standard, 1965, vol. 5, pp.442-445.

H.J. Cialone and J.H. Holbrook: ASTM STP962, 1988, pp. 134–52.

H. P. V. Leeuwen: Eng. Fract. Mec., 1974, vol. 6, no. 1, pp.141-161.

P. Sofronis and R. M. McMeeking: J. Mech. Phys. Solids, 1989, vol. 37, no. 3, pp.317-350.

Y. Wada, Y. Tanaka, T. Iwadate, T. Ohmi and A. T. Yokobori, Jr.: J. Jpn. Inst. Met., 2007, vol. 71, no. 9, pp. 772-780.

JPVRC, Measurement Method and Evaluation of the Hydrogen Embrittlement Threshold Stress Intensity Factor (KIH), The Iron and Steel Institute of Japan, Tokyo, 1989 (in Japanese).

Acknowledgments

This work was supported in part by JSPS KAKENHI Grant Number 25420006. The authors would like to thank the TG 8 subcommittee of JPVRC for their donation of specimens. We also would like to express our gratitude to Mr. N. Mukaimachi and Mr. S. Kanamaru of JGC Corporation for their assistance in finite element analysis modeling, and to Mr. S. Takagi, former graduate student at Ibaraki University, for his assistance during the preparation of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 28, 2014.

Rights and permissions

About this article

Cite this article

Konosu, S., Shimazu, H. & Fukuda, R. Tearing Resistance Properties of Cr-Mo Steels with Internal Hydrogen Determined by the Potential Drop Method. Metall Mater Trans A 46, 5626–5637 (2015). https://doi.org/10.1007/s11661-015-3145-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3145-4