Abstract

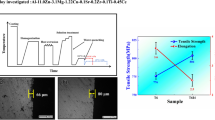

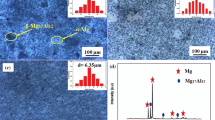

The influence of 0.72 pct Zn addition on the tensile properties of Al-2.7Cu-1.7Li-0.3Mg alloys was investigated. Their intergranular corrosion (IGC) dependence on aging [T6 type at 423 K (150 °C) and 448 K (175 °C) and T8 type at 423 K (150 °C)] time was studied. An IGC diagram associated with aging process was established. The addition of 0.72 pct Zn enhanced the strength of the Al-Li alloy with T6 type aging at 448 K (175 °C). With aging process, the corrosion mode of the T6-aged Al-Li alloys was changed in the following order: pitting and local IGC (initial aging stage), general IGC (underaging stage), local IGC (near peak-aging stage), and pitting (overaging stage) again. The IGC depth was increased first and then decreased with aging time extension. The corrosion potential change of grains and the microstructure variation were used to explain the IGC sensitivity of the Al-Li alloy with different tempers. Meanwhile, 0.72 pct Zn addition decreased the IGC sensitivity of the Al-Li alloy, especially the T6-aged Al-Li alloy.

Similar content being viewed by others

References

J.P. Immarigeon, R.T. Holt, A.K. Koul, L. Zhao, W. Wallace, and J.C. Beddoes: Mater. Charact., 1995, vol. 35, pp. 41–67.

R.J. Rioja and J. Liu. Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3325–37.

T. Warner: Mater. Sci. Forum, 2006, vols. 519–521, pp. 1271–78.

N.E. Prasad, A. Gokhale, and R.J.H Wanhill: Aluminum-Lithium Alloys: Processing, Properties, and Applications, Elsevier, Waltham, MA, 2014, pp. 63–65 and 261.

B.P. Huang and Z.Q. Zheng: Acta Mater., 1998, vol. 46, pp. 4381–93.

C. Giummarra, B. Thomas, and R.J. Rioja: Proc. Light Met. Technol. Conf., Saint Sauvert, PQ, Canada. 24–26, 2007.

X.H. Zhu, Z.Q. Zheng, and S. Zhong: Chin. J. Nonferrous Met., 2010, vol. 20, pp. 1861–67 (in Chinese).

S.J. Yang, Z. Lu, S.L. Dai, Y.F. Han, and M.G. Yan: Trans. Nonferrous Met. Soc. China, 2006, vol. 16, pp. s1649–54.

S. Ohsaki, K. Kobayashi, M. Iino, and T. Sakamoto: Corros. Sci., 1996, vol. 38, pp. 793–806.

S. Ohsaki, M. Iino, K. Kobayashi, and T. Sakamoto: Jpn. Soc. Mech. Eng., 1999, vol. 42, pp. 288–93.

K. Kobayashi, S. Ohsaki, A. Kamio, T. Sato, and Y. Tsuji: J. Jpn Inst. Light Met., 1992, vol. 42, pp. 211–16.

R.J. Rioja, A. Cho, and P.E. Bretz (Aluminum Company of America, Pittsburgh, PA): US Patent 4,961,792, Oct. 9, 1990.

J.P. Moran, F.S. Bovard, J.D. Chrzan, and P. Vandenburgh: Proc. 13th Int. Conf. Alum. Alloys (ICAA13), Pittsburgh, PA, June 3–7, 2012, John Wiley & Sons, Inc., Hoboken, NJ, pp. 425–30.

J.P. Moran, F.S. Bovard, J.D. Chrzan, R.J. Rioja, and E.L. Colin: Proc. 12th Int. Conf. Alum. Alloys (ICAA12), Yokohama, Japan, Sept. 5–9, 2010, The Japan Institute of Light Metals, Tokyo, Japan, pp. 1492–97.

R.G. Buchheit, D. Mathur, and P.I. Gouma: Proc. Symp. Light Mater. Aerosp. Struct., New Orleans, LA, Feb. 12–14, 2001, TMS, Warrendale, PA, pp. 109–18.

G. Svenningsen, M.H. Larsen, J.C. Walmsley, J.H. Nordlien, and K. Nisancioglu: Corros. Sci., 2006, vol. 48, pp. 1528–43.

M. Ahmad: J. Phys. Coll. (C3), 1987, vol. 48, pp. C3-871–C3-879.

J.R. Pickens, L.S. Kramer, T.J. Langen, and F.H. Heubaum: Proc. 6th Int. Alum.-Lithium Conf., DGM Informationsgesellschaft mbH, Oberursel, Germany, 1992, pp. 357–62.

X.Y. Wei: Ph.D. Dissertation, Central South University, Changsha, 2009.

K.S. Kumar, S.A. Brown, and J.R. Pickens: Acta Mater., 1996, vol. 44, pp. 1899–1915.

V. Proton, J. Alexis, E. Andrieu, J. Delfosse, A. Deschamps, F.D. Geuser, M.-C. Lafont, and C. Blanc: Corros. Sci., 2014, vol. 80, pp. 494–502.

C. Henon and S. Rouault: Proc. 13th Int. Conf. on Alum. Alloys, Pittsburgh, PA, June 3–7, 2012, John Wiley & Sons, Inc., Hoboken, NJ, pp. 431–36.

J.F. Li, C.X. Li, Z.W. Peng, W.J. Chen, and Z.Q. Zheng: J. Alloys Compd., 2008, vol. 460, pp. 688–93.

R.G. Buchheit, J.P. Moran, and G.E. Stoner: Corrosion, 1994, vol. 50, pp. 120–30.

J.E. Kertz, P.I. Gouma, and R.G. Buchheit: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2561–73.

V. Singh, A.K. Mukhopadhyay, and K.S. Prasad: Scripta Mater., 1997, vol. 37, pp. 1519–23.

Acknowledgments

This work was supported by the Teacher’s Research Foundation of Central South University (Grant No. 2013JSJJ001) and The Natural Science Foundation of Ningxia Province (Grant No. NZ13012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 28, 2014.

Rights and permissions

About this article

Cite this article

Li, Jf., Xu, L., Cai, C. et al. Mechanical Property and Intergranular Corrosion Sensitivity of Zn-Free and Zn-Microalloyed Al-2.7Cu-1.7Li-0.3Mg Alloys. Metall Mater Trans A 45, 5736–5748 (2014). https://doi.org/10.1007/s11661-014-2528-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2528-2