Abstract

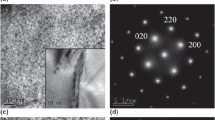

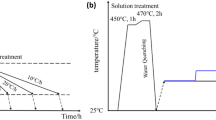

The microstructure, mechanical properties, and intergranular corrosion (IGC) susceptibility of peak-aged 2195 Al-Cu-Li alloy at different temperatures were investigated. The results showed that the microhardness and tensile properties of the alloy were significantly improved by increasing the aging temperature, while the ductility and corrosion resistance decreased. The medium-temperature aged sample could obtain optimal mechanical properties and acceptable corrosion resistance in comparison with other samples. A competitive relationship was observed between T1 (Al2CuLi) and θ' (Al2Cu) phases during aging treatment, where a higher aging temperature promoted nucleation of the T1 phase, which played the dominant role in strengthening the alloy. However, the θ' phase precipitation was inhibited. The improvement of corrosion susceptibility was mainly related to fine intragranular precipitates, continuous grain boundary precipitates, and a narrow precipitate-free zone. Furthermore, the relationship between the open circuit potential and the IGC sensitivity was discussed to determine the corrosion mechanism of the alloy.

Similar content being viewed by others

References

K. Yan, T.Y. Wang and H.M. Liang, Effects of Rotation Speed on Microstructure and Mechanical Properties of 2060 Al-Cu-Li Alloy in Friction Stir Welding, J. Mater. Eng. Perform., 2018, 11, p 5803–5814.

K.R. Emil, D. Uyime and A. Victor, The Effect of Acid Pickling on the Corrosion Behavior of a Cerium Conversion-Coated AA2198-T851 Al-Cu-Li Alloy, J. Mater. Eng. Perform., 2020, 1, p 167–174.

H. Ning, J.F. Li and P.C. Ma, Evolution of Aging Precipitates in an Al-Cu-Li Alloy with 1.5 wt% Li Concentration, Vacuum., 2020, 182, p 109677.

Y.X. Wang, X.W. Ma and H.K. Xi, Effects of Pre-stretching and Aging Treatments on Microstructure, Mechanical Properties, and Corrosion Behavior of Spray-Formed Al-Cu-Li Alloy 2195, J. Mater. Eng. Perform., 2020, 10, p 6960–6973.

H.Y. Li, W. Kang and X.C. Lu, Effect of Age-forming on Microstructure, Mechanical and Corrosion Properties of a novel Al–Li alloy, J. Alloys. Compd., 2015, 640, p 210–218.

J.S. Tao, L. Zhang and G.H. Wu, Effect of Heat Treatment on the Microstructure and Mechanical Properties of Extruded Al-4Cu-1Li-0.4Mg-0.4Ag-0.18Zr Alloy, Mater. Sci. Eng. A., 2018, 717, p 11–19.

X.X. Chen, X.W. Ma and H.K. Xi, Effects of Heat Treatment on the Microstructure and Mechanical Properties of Extruded 2196 Al-Cu-Li Alloy, Mater. Des., 2020, 192, p 108746.

V.A. Peters, B. Gault and F.D. Geuser, Microstructural Evolution during Ageing of Al-Cu-Li-x Alloys, Acta Mater., 2014, 66, p 199–208.

J.F. Li, Z.H. Ye and D.Y. Liu, Influence of Pre-deformation on Aging Precipitation Behavior of Three Al–Cu–Li Alloys, Acta. Metall. Sin. (Engl. Lett.), 2017, 30, p 133–145.

A. Medjahed, A. Henniche and M. Derradji, Effects of Cu/Mg Ratio on the Microstructure, Mechanical and Corrosion Properties of Al-Cu-Li-Cu-Mg-X Alloys, Mater. Sci. Eng. A., 2018, 718, p 241–249.

A.T. Chen, G.H. Wu and L. Zhang, Microstructural Characteristics and Mechanical Properties of Cast Al-3Li-xCu-0.2Zr Alloy, Mater. Sci. Eng. A., 2016, 677, p 29–40.

B. Chen, C.H. Li and S.C. He, Corrosion Behavior of 2099 Al-Cu-Li Alloy in NaCl Aqueous Solution, J. Mater. Res., 2014, 12, p 1344–1353.

C.S. Lee and P.I. Choi, Stress Corrosion Cracking Behavior of Al-Cu-Li-Mg-Zr(-Ag) Alloys, Met. Mater. Int., 2002, 8, p 191–196.

M. Guérin, E. Andrieu and G. Odemer, Effect of Varying Conditions of Exposure to an Aggressive Medium on the Corrosion Behavior of the 2050 Al-Cu-Li Alloy, Corrosion Sci., 2014, 85, p 455–470.

V. Proton, J. Alexis and E. Andrieu, The Influence of Artificial Ageing on the Corrosion Behaviour of a 2050 Aluminium-Copper-Lithium Alloy, Corrosion Sci., 2014, 80, p 494–502.

Y. Lin, C. Lu and C.Y. Wei, Effect of Aging Treatment on Microstructures, Tensile properties and Intergranular Corrosion Behavior of Al-Cu-Li Alloy, Mater. Charact., 2018, 141, p 163–168.

Y. Ma, X. Zhou and Y. Liao, Localised Corrosion in AA 2099–T83 Aluminium-Lithium Alloy: The Role of Grain Orientation, Corrosion Sci., 2016, 107, p 41–48.

X.X. Zhang, X.R. Zhou and T. Hashimoto, Corrosion Behaviour of 2A97-T6 Al-Cu-Li alloy: The Influence of Non-uniform Precipitation, Corrosion Sci., 2018, 132, p 1–8.

U. Donatus, M. Terada and C.R. Ospina, On the AA2198-T851 Alloy Microstructure and its Correlation with Localized Corrosion Behavior, Corrosion Sci., 2018, 131, p 300–309.

P.S. Chen and B.N. Bhat, Time-Temperature-Precipitation Behavior in Al-Li Alloy 2195, NASA technical report, 211548, 2002.

H.Y. Li, D.S. Huang and W. Kang, Effect of Different Aging Processes on the Microstructure and Mechanical Properties of a Novel Al-Cu-Li Alloy, J. Mater. Sci. Technol., 2016, 32, p 1049–1053.

H.J. Kim and M. Niinomi, The Role of Microstructures on the Strengthening Mechanisms of a Thermomechanically Processed 2091 Al–Li alloy, Mater. Sci. Eng. A., 2000, 284, p 14–24.

B. Jiang, F.H. Cao, H.S. Wang, D.Q. Yi and Y. Jiang, Effect of Aging Time on the Microstructure Evolution and Mechanical Property in an Al-Cu-Li Alloy Sheet, Mater. Sci. Eng. A., 2019, 740–741, p 157–164.

B. Decreus, A. Deschamps and F. Geuser, Influence of Natural Ageing and Deformation on Precipitation in an Al-Cu-Li Alloy, Adv. Eng. Mater., 2013, 11, p 1082–1085.

S.F. Zhang, W.D. Zeng and W.H. Yang, Ageing Response of a Al–Cu–Li 2198 Alloy, Mater. Des., 2014, 63, p 368–374.

J.F. Li, J.L. Huang and D.Y. Liu, Distribution and Evolution of Aging Precipitates in Al-Cu-Li Alloy with High Li Concentration, Trans. Nonferrous Met. Soc. China., 2019, 29, p 15–24.

X.X. Zhang, Y.B. Jiao and Y. Yu, Intergranular Corrosion in AA2024-T3 Aluminium Alloy: The Influence of Stored Energy and Prediction, Corrosion Sci., 2019, 155, p 1–12.

G. Svenningsen, J. ErikLein and A. Bjørgum, Effect of Low Copper Content and Heat Treatment on Intergranular Corrosion of Model AlMgSi Alloys, Corrosion Sci., 2006, 48, p 226–242.

X.H. Xu, Y.L. Deng and S.Q. Chi, Effect of Interrupted Ageing Treatment on the Mechanical Properties and Intergranular Corrosion Behavior of Al-Mg-Si Alloys, J. Mater. Res. Technol., 2020, 9, p 230–241.

J. Zhang, C. Wang and Y. Zhang, Effects of Creep Aging upon Al-Cu-Li Alloy: Strength, Toughness and Microstructure, J. Alloy. Compd., 2018, 764, p 452–459.

B. Jiang, H.S. Wang and Y. Tian, Effects of Aging Time on Corrosion Behavior of an Al-Cu-Li Alloy, Corro Sci., 2020, 173, p 108759.

S.L. Hou, D. Zhang and Y.L. Pan, Dependence of Microstructure, Mechanical Properties, and Intergranular Corrosion Behavior of Al-5.1Mg-3.0Zn-0.15Cu Alloys with High Temperature Pre-treatment, Mater. Charact., 2020, 168, p 110512.

G. Svenningsen, M.H. Larsen, J.H. Nordlien and K. Nisancioglu, Effect of Thermomechanical History on Intergranular Corrosion of Extruded AlMgSi(Cu) Model Alloy, Corros. Sci., 2006, 48, p 3969–3987.

J.C. Huang and A.J. Ardell, Precipitation Strengthening of Binary Al–Li Alloys by δ’ Precipitates, Mater. Sci. Eng. A., 1988, 104, p 149–156.

X.H. Wang, J.H. Wang, Xin Yue and Y. Gao, Effect of Aging Treatment on the Exfoliation Corrosion and Stress Corrosion Cracking Behaviors of 2195 Al-Cu-Li Alloy, Mater. Des., 2015, 67, p 596–605.

G. Svenningsen, M.H. Larsen and J.C. Walmsley, Effect of Artificial Aging on Intergranular Corrosion of Extruded AlMgSi Alloy with Small Cu Content, Corrosion Sci., 2006, 48, p 1528–1543.

J.F. Li, C.X. Li and Z.W. Peng, Corrosion Mechanism Associated with T1 and T2 Precipitates of Al-Cu-Li Alloys in NaCl Solution, J. Alloy. Compd., 2008, 460, p 688–693.

M. Guérin, J. Alexis and E. Andrieu, Identification of the Metallurgical Parameters Explaining the Corrosion Susceptibility in a 2050 Aluminium Alloy, Corrosion Sci., 2016, 102, p 291–300.

Y. Zou, L.F. Cao and X.D. Wu, Effect of Ageing Temperature on Microstructure, Mechanical Property and Corrosion Behavior of Aluminum Alloy 7085, J. Alloy. Compd., 2020, 823, p 153792.

L.M. Yao and R.K. Wang, Influences of Nano-structured Thermal Stability on the Intergranular Corrosion of High-Carbon Austenitic Heat-Resistant Steel, J. Mater. Eng. Perform., 2021, 1, p 783–793.

Y.L. Ma, X.R. Zhou and X.M. Meng, Influence of Thermomechanical Treatments on Localized Corrosion Susceptibility and Propagation Mechanism of AA2099 Al-Cu-Li Alloy, Trans. Nonferrous Met. Soc. China., 2016, 26, p 1472–1481.

Z.X. Wang, P. Chen and H. Li, The Intergranular Corrosion Susceptibility of 2024 Al Alloy during Re–ageing after Solution Treating and Cold–rolling, Corrosion Sci., 2017, 114, p 156–168.

J.L. Huang, J.F. Li, D.Y. Liu, R.F. Zhang, Y.L. Chen, X.H. Zhang, P.C. Ma, R.K. Gupta, and N. Birbilis, Correlation of Intergranular Corrosion Behaviour with Microstructure in Al-Cu-Li Alloy, Corrosion Sci., 2018, 139, p 215–226.

Acknowledgment

This work was supported by the National Foundation of China (No.414010003), the Changsha Municipal Natural Science Foundation (kq2007085) and the Project of Changsha Science and Technology (k1705013). The authors would prefer to thank Mrs. Yingchun Wan for the help of sample preparation and paper writing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xia, L., Li, Y., Huang, M. et al. Influence of Aging Treatment on the Corrosion Susceptibility and Mechanical Properties of Peak-Aged 2195 Al-Cu-Li Alloy. J. of Materi Eng and Perform 31, 631–642 (2022). https://doi.org/10.1007/s11665-021-06158-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06158-5