Abstract

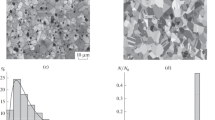

Ni-based alloys with high Cr contents are not only known for their excellent high temperature and hot corrosion resistance, but are also known for poor mechanical properties and difficult workability. Powder metallurgical (PM) manufacturing of alloys may overcome several of the shortcomings encountered in materials manufacturing involving solidification. In the present work, six PM Ni-based alloys containing 35 to 45 wt pct Cr and 3.5 to 6 wt pct Nb were produced and compacted via hot isostatic pressing. Samples were heat treated for up to 1656 hours at either 923 K or 973 K (650 °C or 700 °C), and the microstructures and mechanical properties were quantified and compared to thermodynamic calculations. For the majority of the investigated alloys, the high Cr and Nb contents caused development of primary populations of globular α-Cr and δ (Ni3Nb). Transmission electron microscopy of selected alloys confirmed the additional presence of metastable γ″ (Ni3Nb). A co-dependent growth morphology was found, where the preferred growth direction of γ″, the {001} planes of γ-Ni, caused precipitates of both α-Cr and δ to appear in the form of mutually perpendicular oriented disks or plates. Solution heat treatment at 1373 K (1100 °C) followed by aging at 973 K (700 °C) produced a significant strength increase for all alloys, and an aged yield strength of 990 MPa combined with an elongation of 21 pct is documented for Ni 40 wt pct Cr 3.5 wt pct Nb.

Similar content being viewed by others

References

R. A. Rapp: Corrosion Science, 2002, vol. 44, pp. 209-221.

J. Stringer: Materials Science and Technology, 1987, vol. 3, pp. 482-493.

F. Pettit: Oxidation of Metals, 2011, vol. 76, pp. 1-21.

H. Singh, D. Puri, S. Prakash: Reviews on Advanced Materials Science, 2007, vol. 16, pp. 27-50.

L. Zheng, C. Xiao, G. Zhang, B. Han and D. Tang: Journal of Alloys and Compounds, 2012, vol. 527, pp. 176-183.

P. J. Ennis and P. J. Bridges: Journal of the Institute of Metals, 1972, vol. 100, pp. 346-352.

P. J. Parry and P. J. Bridges and B. Taylor: Journal of the Institute of Metals, 1969, vol. 97, pp. 373-381.

J. Dong, Z. Bi, N. Wang, X. Xie, and Z. Wang: Proc. Int. Sympos. Superalloys, ed. 1, Wiley, Pittsburgh, 2008, pp. 41–50.

M. P. Brady, I. M. Anderson, M. L. Weaver, H. M. Meyer, L. R. Walker, M. K. Miller, D. J. Larson, I. G. Wright, V. K. Sikka, A. Rar, G. M. Pharr, J. R. Keiser and C. A. Walls: Materials Science and Engineering A, 2003, vol. A358, pp. 243-254.

M. C. Gao, Ö. N. Dogan, P. King, A. D. Rollett and M. Widom: JOM, 2008, vol. 60, pp. 61-65.

H. V. Atkinson and S. Davies: Metallurgical and Materials Transactions A, 2000, vol. 31A, pp. 2981-3000.

H.L. Eiselstein and D.J. Tillack: Proc. Int. Sympos. Superalloys 718, 625 and Var. Deriv, ed. 1, Wiley, Pittsburgh, 1991, pp. 1–14.

A. Devaux, L. Nazé, R. Molins, A. Pineau, A. Organista, J. Y. Guédou, J. F. Uginet and P. Héritier: Materials Science and Engineering A, 2008, vol. A486, pp. 117-122.

S. Mahadevan, S. Nalawade, J. B. Singh, and A. Verma: Proc. 7th Int. Sympos. Superalloy 718 Deriv, ed. 1, Wiley, Pittsburgh, 2010, pp. 737–50.

N. Saunders and A. P. Miodownik: CALPHAD (Calculation of Phase Diagrams): A Comprehensive Guide, ed. 1, Oxford, Pergamon, 1998.

J. O. Andersson, T. Helander, L. Höglund, P. Shi and B. Sundman: Calphad, 2002, vol. 26, no. 2, pp. 273-312.

D. Srinivasan: Materials Science and Engineering A, 2004, vol. A364, pp. 27-34.

J. F. Radavich: Proceedings of the 6th International Symposium on Superalloys 718, 625, 706 and Various Derivatives, ed. 1, Wiley, Pittsburgh, 2010, pp. 409–15.

Z. Bi, J. Dong, M. Zhang, L. Zheng and X. Xie: International Journal of Minerals, Metallurgy and Materials, 2010, vol. 17, no. 3, pp. 312-317.

B. Sonderegger: Ultramicroscopy, 2006, vol. 106, pp. 941-950.

R.F. Egerton: Reports on Progress in Physics, 2009, vol. 72, art. no. 016502.

M. Kong, R. N. Bhattacharya, C. James and A. Basu: Geological Society of America Bulletin, 2005, vol. 117, no. 1, pp. 244-249.

D. Drouin, A. R. Couture, D. Joly, X. Tastet, V. Aimez and R. Gauvin: Scanning, 2007, vol. 29, pp. 92-101.

Thermo-Calc Software TCNI5 Ni-Based Superalloys Database version 5.1, http://www.thermocalc.com.

N. Saunders: Proc. Int. Sympos. Superalloys, ed. 1, Wiley, Pittsburgh, 1996, pp. 101–10.

J. He, S. Fukuyama and K. Yokogawa: Journal of Materials Science and Technology, 1994, vol. 10, pp. 293-303.

T. Furuhara, K. Wada and T. Maki: Metallurgical and Materials Transactions A, 1995, vol. 26A, pp. 1971-1978.

G. A. Rao, M. Kumar, M. Srinivas and D. S. Sarma: Materials Science and Engineering A, 2003, vol. A355, pp. 114-125.

B.A. Baker, G.D. Smith, V.W. Hartmann, L.E. Shoemaker, and S.A. McCoy: Corrosion 2002, NACE International, Houston, TX, Paper No. 02394, 2002.

Davis, J. R., Mills, K. M., & Lampman, S. R. (1990) Metals Handbook, vol. 1. Properties and Selection: Irons, Steels, and High-Performance Alloys, 10th edition, ASM International, Materials Park, OH, pp. 958–61.

Acknowledgments

The authors gratefully acknowledge Flemming Bjerg Grumsen at the Technical University of Denmark, for production of TEM lamellae and TEM operation. Funding for this project was provided by MAN Diesel & Turbo SE and the Danish Ministry of Science, Innovation and Higher Education.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 20, 2013.

Appendix

Appendix

See appendix Tables VI and VII

Rights and permissions

About this article

Cite this article

Bihlet, U.D., Dahl, K.V. & Somers, M.A.J. Microstructure of Precipitation Hardenable Powder Metallurgical Ni Alloys Containing 35 to 45 pct Cr and 3.5 to 6 pct Nb. Metall Mater Trans A 45, 4796–4809 (2014). https://doi.org/10.1007/s11661-014-2469-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2469-9