Abstract

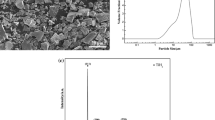

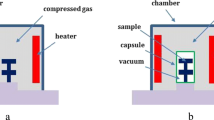

Pure Ti (99.5 pct) powders after processing with ball milling (BM) were consolidated to disc-shaped samples with 10-mm diameter and 0.8-mm thickness at room temperature using high-pressure torsion (HPT). A relative density as high as 99.9 pct, high bending and tensile strengths of 2.55 to 3.45 and 1.35 GPa, respectively, and a moderate ductility of 8 pct with an ultrafine grained structure are achieved after cold consolidation with HPT, which exceed those of hot consolidation methods. X-ray diffraction (XRD) analysis showed that a phase transformation occurs from α phase to ω phase during HPT under a pressure of 6 GPa as in bulk pure Ti, whereas no phase transformation is detected after processing with BM alone. It was confirmed that the strength and ductility are improved by a combined application of BM and HPT when compared with other severe plastic deformation methods applied to Ti and Ti-6 pct Al-4 pct V, so that no alloying elements are required for the achievement of a comparable strength and ductility.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Prog. Mater. Sci., 2000, vol. 45, pp. 103–89.

A.V. Korznikov, I. Safarov, D.V. Laptionok, and R.Z. Valiev: Acta Metall. Mater., 1991, vol. 39, pp. 3193–97.

V.A. Zilbershtein, N.P. Chistotina, A.A. Zharov, N.S. Grishina, and E.I. Estrin: Fiz. Metal. Metalloved., 1975, vol. 39, pp. 445–47.

P.W. Bridgman: Phys. Rev., 1935, vol. 48, pp. 825–47.

H. Shen, B. Guenther, A.V. Koanikov, and R.Z. Valiev: Nanostruct. Mater., 1995, vol. 6, pp. 385–88.

R.Z. Valiev, R.S. Mishra, J. Groza, and A.K. Mukherjee: Scripta Mater., 1996, vol. 34, pp. 1443–48.

J. Sort, A.P. Zhilyaev, M. Zielinska, J. Nogues, S. Surinach, J. Thibault, and M.D. Baro: Acta Mater., 2003, vol. 51, pp. 6385–93.

Z. Lee, F. Zhou, R.Z. Valiev, E.J. Lavernia, and S.R. Nutt: Scripta Mater., 2004, vol. 51, pp. 209–14.

I.V. Alexandrov, Y.T. Zhu, T.C. Lowe, R.K. Islamgaliev, and R.Z. Valiev: Nanostruct. Mater., 1998, vol. 10, pp. 45–54.

I.V. Alexandrov, Y.T. Zhu, T.C. Lowe, and R.Z. Valiev: Powder Metall., 1998, vol. 41, pp. 11–13.

I.V. Alexandrov, Y.T. Zhu, T.C. Lowe, R.K. Islamgaliev, and R.Z. Valiev: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2253–60.

V.V. Stolyarov, Y.T. Zhu, T.C. Lowe, R.K. Islamgaliev, and R.Z. Valiev: Mater. Sci. Eng. A, 2000, vol. 282, pp. 78–85.

R. Kuzel, Z. Matej, V. Cherkaska, J. Pesicka, J. Cizek, I. Prochazka, and R.K. Islamgaliev: J. Alloys Compd., 2004, vol. 378, pp. 242–47.

R.K. Islamgaliev, W. Buchgraber, Y.R. Kolobov, N.M. Amirkhanov, A.V. Sergueeva, K.V. Ivanov, and G.P. Grabovetskaya: Mater. Sci. Eng. A, 2001, vols. 319–321, pp. 872–76.

T. Tokunaga, K. Kaneko, and Z. Horita: Mater. Sci. Eng. A, 2008, vol. 490, pp. 300–04.

T. Tokunaga, K. Kaneko, K. Sato, and Z. Horita: Scripta Mater., 2008, vol. 58, pp. 735–38.

E. Menendez, J. Sort, V. Langlais, A. Zhilyaev, J.S. Munoz, S. Surinach, J. Nogues, and M.D. Baro: J. Alloys Compd., 2007, vols. 434–435, pp. 505–08.

E. Menendez, G. Salazar-Alvarez, A.P. Zhilyaev, S. Surinach, M.D. Baro, J. Nogues, and J. Sort: Adv. Funct. Mater., 2008, vol. 18, pp. 3293–98.

H. Li, A. Misra, Y. Zhu, Z. Horita, C.C. Koch, and T.G. Holesinger: Mater. Sci. Eng. A, 2009, vol. 523, pp. 60–64.

H. Li, A. Misra, Z. Horita, C.C. Koch, N.A. Mara, P.O. Dickerson, and Y. Zhu: J. Appl. Phys., 2009, vol. 95, p. 071907.

A. Bachmaier, A. Hohenwartera, and R. Pippana: Scripta Mater., 2009, vol. 61, pp. 1016–19.

W.J. Botta Filho, J.B. Fogagnolo, C.A.D. Rodrigues, C.S. Kiminami, C. Bolfarini, and A.R. Yavari: Mater. Sci. Eng. A, 2004, vols. 375–377, pp. 936–941.

J. Sort, D.C. Ile, A.P. Zhilyaev, A. Concustell, T. Czeppe, M. Stoica, S. Surinach, J. Eckert, and M.D. Baro: Scripta Mater., 2004, vol. 50, pp. 1221–25.

A.R. Yavari, W.J. Botta Filho, C.A.D. Rodrigues, C. Cardoso, and R.Z. Valiev: Scripta Mater., 2002, vol. 46, pp. 711–16.

Z. Kovacs, P. Henits, A.P. Zhilyaev, and A. Revesz: Scripta Mater., 2006, vol. 54, pp. 1733–37.

N. Boucharat, R. Hebert, H. Rosner, R.Z. Valiev, and G. Wilde: J. Alloys Compd., 2007, vols. 434–435, pp. 252–54.

T. Czeppe, G. Korznikova, J. Morgiel, A. Korznikov, N.Q. Chinh, P. Ochin, and A. Sypien: J. Alloys Compd., 2009, vol. 483, pp. 74–77.

K. Edalati, Y. Yokoyama, and Z. Horita: Mater. Trans., 2010, vol. 51, pp. 23–26.

A.P. Zhilyaev, A.A. Gimazov, G.I. Raab, and T.G. Langdon: Mater. Sci. Eng. A, 2008, vol. 486, pp. 123–28.

A.P. Zhilyaev, S. Swaminathan, A.A. Gimazov, T.R. McNelley, and T.G. Langdon: J. Mater. Sci., 2008, vol. 43, pp. 7451–56.

K. Edalati and Z. Horita: Scripta Mater., 2010, vol. 63, pp. 174–77.

J.S. Benjamin: Sci. Am., 1976, vol. 234, pp. 40–48.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1–184.

ASM Handbook, vol. 7, Powder Metal Technologies and Applications, 10th ed., ASM INTERNATIONAL, Metals Park, OH, 1998.

C.J. Lu, J. Zhang, and Z.Q. Li: J. Alloys Compd., 2004, vol. 381, pp. 278–83.

Y.Y. Li, C. Yang, W.P. Chen, X.Q. Li, and M. Zhu: J. Mater. Res., 2007, vol. 22, pp. 1927–32.

P. Chatterjee and S.P. Sen Gupta: Philos. Mag. A, 2001, vol. 81, pp. 49–60.

I. Manna, P.P. Chattopadhyay, P. Nandi, F. Banhart, and H.J. Fecht: J. Appl. Phys., 2003, vol. 93, pp. 1520–24

J. Dutkiewicz, J. Kusnierz, M. Maziarz, M. Lejkowska, H. Garbacz, M. Lewandowska, A. Dobromyslov, and K.J. Kurzydlowski: Phys. Status Solidi A, 2005, vol. 202, pp. 2309–20.

F. Sun, A. Zuniga, P. Rojas, and E.J. Lavernia: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2069–78.

H. Fujiwara, T. Sekiguchi, and K. Ameyama: Int. J. Mater. Res., 2009, vol. 100, pp. 796–99.

Y.K. Vohra, S.K. Sikka, S.N. Vaidya, and R. Chidamberan: J. Phys. Chem. Solids, 1977, vol. 38 (11), pp. 1293–96.

A.R. Kilmametov, A.V. Khristoforova, G. Wilde, and R.Z. Valiev: Z. Kristallogr. Suppl., 2007, vol. 26, pp. 339–44.

Y. Ivanisenko, A. Kilmametov, H. Rosner, and R.Z. Valiev: Int. J. Mater. Res., 2008, vol. 99, pp. 36–41.

Y. Todaka, J. Sasaki, T. Moto, and M. Umemoto: Scripta Mater., 2008, vol. 59, pp. 615–18.

K. Edalati, E. Matsubara, and Z. Horita: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2079–86.

K. Edalati, Z. Horita, S. Yagi, and E. Matsubara: Mater. Sci. Eng. A, 2009, vol. 523, pp. 277–81.

ASTM E290, Standard Test Methods for Bend Testing of Material for Ductility, ASTM International, West Conshohocken, PA, 2009.

K. Edalati, Z. Horita, and T.G. Langdon: Scripta Mater., 2009, vol. 60, pp. 9–12.

K. Edalati, T. Fujioka, and Z. Horita: Mater. Trans., 2009, vol. 50, pp. 44–50.

K. Edalati, Z. Horita, M. Tanaka, and K. Higashida: Adv. Mater. Res., 2010, vol. 89–91, pp. 171–76.

A. Vorhauer and R. Pippan: Scripta Mater., 2004, vol. 51, pp. 921–25.

K. Edalati, T. Fujioka, and Z. Horita: Mater. Sci. Eng. A, 2008, vol. 497, pp. 168–73.

K. Edalati, Z. Horita, and Y. Mine: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2136–41.

M. Kai, Z. Horita, and T.G. Langdon: Mater. Sci. Eng. A, 2008, vol. 488, pp. 117–24.

V.V. Stolyarov, Y.T. Zhu, T.C. Lowe, and R.Z. Valiev: Mater. Sci. Eng. A, 2001, vol. 303 pp. 82–89.

V.V. Stolyarov, Y.T. Zhu, I.V. Alexandrov, T.C. Lowe, and R.Z. Valiev: Mater. Sci. Eng. A, 2003, vol. 343, pp. 43–50.

D. Terada, S. Inoue, and N. Tsuji: J. Mater. Sci., 2007, vol. 42, pp. 1673–81.

Y.H. Zhao, Y.Z. Guo, Q. Wei, A.M. Dangelewicz, C. Xu, Y.T. Zhu, T.G. Langdon, Y.Z. Zhou, and E.J. Lavernia: Scripta Mater., 2008, vol. 59, pp. 627–30.

Acknowledgments

We thank Professor Kenji Higashida, Kyushu University, for permitting the use of the bending test facility, and Dr. Masaki Tanaka, Kyushu University, for helpful assistance in using a bending test machine. We are also grateful to Professor H. Miura, Kyushu University, for lending us a facility of the density measurement. One of the authors (KE) thanks the Islamic Development Bank for a scholarship. This work was supported, in part, by a Grant-in-Aid for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology of Japan in the Priority Area “Giant Straining Process for Advanced Materials Containing Ultra-High Density Lattice Defects” and, in part, by Kyushu University Interdisciplinary Programs in Education and Projects in Research Development (P&P).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 17, 2009.

Rights and permissions

About this article

Cite this article

Edalati, K., Horita, Z., Fujiwara, H. et al. Cold Consolidation of Ball-Milled Titanium Powders Using High-Pressure Torsion. Metall Mater Trans A 41, 3308–3317 (2010). https://doi.org/10.1007/s11661-010-0400-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0400-6