Abstract

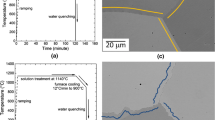

This study focuses on the microstructural features that enhance the resistance of ALLVAC 718Plus to grain boundary creep cracking during testing of samples at 704 °C in both dry and moist air. Fully recrystallized structures were found to be susceptible to brittle grain boundary cracking in both environments. Detailed transmission electron microscopy (TEM) microstructural characterization reveals features that are believed to lead to resistance to grain boundary cracking in the resistant microstructures. It is suggested that dislocation substructures found within the grains of resistant structures compete with the high-angle grain boundaries for oxygen, thereby reducing the concentration of oxygen on the grain boundaries and subsequent embrittlement. In addition, electron backscatter diffraction (EBSD) misorientation maps reveal that special boundaries (i.e., Σ3 boundaries) resist cracking. This is in agreement with previous findings on the superalloy INCONEL 718. Furthermore, it is observed that cracks propagate along high-angle boundaries. This study also shows that in this case, the presence of delta phase at the grain boundaries does not by itself produce materials that are resistant to grain boundary cracking.

Similar content being viewed by others

Notes

ALLVAC is a trademark of ATI, Charolette, NC.

INCONEL is a trademark of Special Metals Corporation, Huntington, WV.

WASPALOY is a trademark of United Technologies, Hartford, CT.

References

Superalloys 718, 625, 706 and Various Derivatives, 2005, E.A. Loria, ed., TMS, Warrendale, PA, 2005.

H.F. Merrick: Proc. Symp. Precipitation Process in Solids, TMS-AIME, Warrendale, PA, 1978, pp. 161–90.

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee: Metall. Trans. A, 1988, vol. 19A, pp. 453–65.

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee: Metall. Trans. A, 1992, vol. 23A, pp. 2015–28.

W.D. Cao: Superalloys 718, 625, 706 and Various Derivatives, E.A. Loria, ed., TMS, Warrendale, PA., 2005, pp. 165–67.

Advanced Materials and Processes, ASM, Materials Park, OH, 2001, vol. 159, p. 96.

D.A. Woodford: Energy Mater., 2006, vol. 1, pp. 59–79.

P. Valerio, M. Gao, and R.P. Wei: Scripta Metall., 1995, vol. 32, pp. 1169–74.

R.W. Hayes: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2596–2606.

U. Krupp, W.M. Kane, C. Laird, and C.J. McMahon: Mater. Sci. Eng., A, 2004, vols. A387–389, pp. 409–13.

U. Krupp, W.M. Kane, X. Liu, O. Deuber, C. Laird, and C.J. McMahon, Jr.: Mater. Sci. Eng., A, 2003, vol. A349, pp. 213–17.

Y. Gao, M. Kumar, R.L. Nalla, and R.O. Ritchie: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 3325–33.

Y. Gao, J.S. Stölken, M. Kumar, and R.O. Ritchie: Acta Mater., 2007, vol. 55, pp. 3155–67.

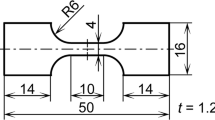

R.W. Hayes, K. Johnson, E. Thompson, and A. Aichlmayr: Mater. Sci. Eng., A, 2009, vols. 510–511, pp. 256–61.

R.W. Hayes, D.F. Smith, E.A. Wanner, and J.C. Earthman: Mater. Sci. Eng., A, 1994, vol. 177, pp. 43–53.

W.D. Cao and R.L. Kennedy: “Recommendations for Heat Treating Allvac 718 Plus Alloy Parts” Report, ATI Allvac, 2006, pp. 1–17, www.alvac.com.

JCPDS File# 65-2589, calculated from PIZ#0 (ICSD@07/16/02) by Jade 6.x.

R. Cozar and A. Pineau: Metall. Trans., 1973, vol. 4, pp. 47–59.

D.F. Paulonis, J.M. Oblak, and D.S. Duvall: ASM Trans. Q., 1969, vol. 62, pp. 611–22.

D.F. Smith, E.F. Clatworthy, D.G. Tipton, and W.L. Mankins: in Superalloys, J.K. Tien, S.T. Wlodek, H. Morrow III, M. Gell, and G.E. Maurer, eds., ASM INTERNATIONAL, Metals Park, OH, 1980, pp. 521–30.

A. Kimura and H.K. Birnbaum: Acta Metall., 1988, vol. 36, pp. 757–66.

D.R. Muzyka and G.N. Maniar: Met. Eng. Q. ASM, 1969, vol. 11, pp. 23–37.

K.A. Unocic: Doctoral Thesis, The Ohio State University, Columbus, OH, 2008.

V. Gupta, R. Hernandez, and P. Charconnet: Mater. Sci. Eng., A, 2001, vol. 317, pp. 249–56.

B.A. Pint, J.A. Haynes, Y. Zhang, K. More, and I. Wright: Surf. Coat. Technol., 2006, vol. 201, pp. 3852–56.

J. Smialek: JOM, 2006, vol. 58, pp. 29–35.

J. Smialek and G. Morscher: Mater. Sci. Eng., A, 2002, vol. 332, pp. 11–24.

J. Smialek, D. Zhu, and M. Cuy: Scripta Mater., 2008, vol. 59, pp. 67–70.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 7, 2009.

Rights and permissions

About this article

Cite this article

Unocic, K.A., Hayes, R.W., Mills, M.J. et al. Microstructural Features Leading to Enhanced Resistance to Grain Boundary Creep Cracking in ALLVAC 718Plus. Metall Mater Trans A 41, 409–420 (2010). https://doi.org/10.1007/s11661-009-0099-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0099-4