Abstract

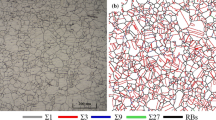

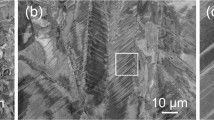

Thermo-mechanical treatment that involves cold deformation and subsequent annealing is given to the material to alter the grain boundary development. In the present work, an attempt has been made to study the grain boundary development in austenitic stainless steel subjected to hot deformation followed by isothermal holding. Axisymmetric compression tests (strain rate of 0.1 s−1) have been performed at temperatures of 900 °C, 1000 °C and 1100 °C to develop a true strain of ~ 0.16. The hot compression test was followed by isothermal holding of samples for times of 2 s, 10 s, 100 s and 1000 s. The electron backscatter diffraction study has been made on the thermo-mechanically treated samples. The developed grain boundaries were analyzed for misorientation angle, Σ3n coincidence site lattice (CSL) boundaries and triple junction (TPJ). The result shows many annealing twins characterized by Σ3 CSL boundary. This Σ3 CSL boundary breaks the material's grain boundary connectivity and significantly changes the average grain size. At temperatures 900 °C and 1000 °C, an increase in holding time leads to an increase in the fraction of triple junction J1. On the other hand, at 1100 °C, the fraction of J1 is not much affected by the holding time. However, an improvement in the fraction of J3, in comparison to 900 °C and 1000 °C, has been observed. A maximum value of ~ 0.12 for J2/(1 − J3) has been observed for the sample hot-deformed and held for 10 seconds at 1100 °C.

Similar content being viewed by others

References

S. Saha, M. Mukherjee, and T.K. Pal, Microstructure, Texture, and Mechanical Property Analysis of Gas Metal Arc Welded AISI 304 Austenitic Stainless Steel, J. Mater. Eng. Perform., 2015, 24(3), p 1125–1139.

X. Fang, K. Zhang, H. Guo, W. Wang, and B. Zhou, Twin-Induced Grain Boundary Engineering in 304 Stainless Steel, Mater. Sci. Eng. A, 2008, 487(1–2), p 7–13.

D.N. Wasnik, V. Kain, I. Samajdar, B. Verlinden, and P.K. De, Controlling Grain Boundary Energy to Make Austenitic Stainless Steels Resistant to Intergranular Stress Corrosion Cracking, J. Mater. Eng. Perform., 2003, 12(4), p 402–407.

V. Randle, Twinning-Related Grain Boundary Engineering, Acta Mater., 2004, 52(14), p 4067–4081.

V. Randle, Grain Boundary Engineering: An Overview after 25 Years, Mater. Sci. Technol., 2010, 26(3), p 253–261.

T. Liu, Q. Bai, X. Ru, S. Xia, X. Zhong, Y. Lu, and T. Shoji, Grain Boundary Engineering for Improving Stress Corrosion Cracking of 304 Stainless Steel, Mater. Sci. Technol. (United Kingdom), 2019, 35(4), p 477–487. https://doi.org/10.1080/02670836.2019.1570661

P. Dolzhenko, M. Tikhonova, M. Odnobokova, R. Kaibyshev, and A. Belyakov, On Grain Boundary Engineering for a 316L Austenitic Stainless Steel, Metals (Basel), 2022, 12(12), p 2185. https://doi.org/10.3390/met12122185

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato, and K. Sakai, Twin-Induced Grain Boundary Engineering for 316 Austenitic Stainless Steel, Acta Mater., 2006, 54(19), p 5179–5184.

V. Randle and R. Jones, Grain Boundary Plane Distributions and Single-Step versus Multiple-Step Grain Boundary Engineering, Mater. Sci. Eng. A, 2009, 524(1–2), p 134–142.

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato, and I. Karibe, Optimization of Grain Boundary Character Distribution for Intergranular Corrosion Resistant 304 Stainless Steel by Twin-Induced Grain Boundary Engineering, Acta Mater., 2002, 50(9), p 2331–2341.

Y. Hu, Q. Bai, S. Xia, K. Liu, Q. He, and G. Xu, Applying Grain Boundary Engineering and Stabilizing Heat Treatment to 321 Stainless Steel for Enhancing Intergranular Corrosion Resistance, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08513-0

H. Mirzadeh, J.M. Cabrera, A. Najafizadeh, and P.R. Calvillo, EBSD Study of a Hot Deformed Austenitic Stainless Steel, Mater. Sci. Eng. A, 2012, 538, p 236–245.

G. Venkata Sarath Kumar, and K. Sivaprasad, Effect of Stacking Fault Energy on Cryo Deformation Behavior of Austenitic Stainless Steels, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08208-6

N.K. Sharma and S. Shekhar, New Perspectives on Twinning Events during Strain-Induced Grain Boundary Migration (SIBM) in Iteratively Processed 316L Stainless Steel, J. Mater. Sci., 2021, 56(1), p 792–814. https://doi.org/10.1007/s10853-020-05240-y

T. Fujii, M. Suzuki, and Y. Shimamura, Susceptibility to Intergranular Corrosion in Sensitized Austenitic Stainless Steel Characterized via Crystallographic Characteristics of Grain Boundaries, Corros. Sci., 2022, 195(November 2021), p 109946. https://doi.org/10.1016/j.corsci.2021.109946

V. Thaveeprungsriporn, P. Sinsrok, and D. Thong-Aram, Effect of Iterative Strain Annealing on Grain Boundary Network of 304 Stainless Steel, Scr. Mater., 2001, 44(1), p 67–71.

F. Shi, P.C. Tian, N. Jia, Z.H. Ye, Y. Qi, C.M. Liu, and X.W. Li, Improving Intergranular Corrosion Resistance in a Nickel-Free and Manganese-Bearing High-Nitrogen Austenitic Stainless Steel through Grain Boundary Character Distribution Optimization, Corros. Sci., 2016, 107, p 49–59.

D. Jorge-Badiola, A. Iza-Mendia, and I. Gutiérrez, Study by EBSD of the Development of the Substructure in a Hot Deformed 304 Stainless Steel, Mater. Sci. Eng. A, 2005, 394(1–2), p 445–454.

M. Wahabi, L. Gavard, J.M. Cabrera, J.M. Prado, and F. Montheillet, EBSD Study of Purity Effects during Hot Working in Austenitic Stainless Steels, Mater. Sci. Eng. A, 2005, 393(1–2), p 83–90.

B.M. Guyot and N.L. Richards, A Study on the Effect of Cold Rolling and Annealing on Special Grain Boundary Fractions in Commercial-Purity Nickel, Mater. Sci. Eng. A, 2005, 395(1–2), p 87–97.

M. Kumar, A.J. Schwartz, and W.E. King, Microstructural Evolution during Grain Boundary Engineering of Low to Medium Stacking Fault Energy Fcc Materials, Acta Mater., 2002, 50(10), p 2599–2612.

H. Beladi, P. Cizek, A.S. Taylor, G.S. Rohrer, and P.D. Hodgson, Static Softening in a Ni-30Fe Austenitic Model Alloy after Hot Deformation: Microstructure and Texture Evolution, Metall. Mater. Trans. A, 2017, 48(2), p 855–867. https://doi.org/10.1007/s11661-016-3880-1

M. Rout, R. Ranjan, S.K. Pal, and S.B. Singh, EBSD Study of Microstructure Evolution during Axisymmetric Hot Compression of 304LN Stainless Steel, Mater. Sci. Eng. A, 2018, 711(January 2018), p 378–388. https://doi.org/10.1016/j.msea.2017.11.059

R. Barbosa and C.M. Sellars, Static Recrystallization of Type 316L Stainless Steel under Hot Working Conditions, Mater. Sci. Forum, 1993, 113–115, p 461–466. https://doi.org/10.4028/www.scientific.net/MSF.113-115.461

E. Dupin, A. Yanagida, and J. Yanagimoto, Modeling Static and Dynamic Kinetics of Microstructure Evolution in Type 316 Stainless Steel, Steel Res. Int., 2014, 85(6), p 1099–1108.

G.R. Stewart and J.J. Jonas, Static and Dynamic Strain Aging at High Temperatures in 304 Stainless Steel, ISIJ Int., 2004, 44(7), p 1263–1272. https://doi.org/10.2355/isijinternational.44.1263

D.G. Brandon, The Structure of High-Angle Grain Boundaries, Acta Metall., 1966, 14(1), p 1479–1484.

D.M. Saylor, A. Morawiec, and G.S. Rohrer, The Relative Free Energies of Grain Boundaries in Magnesia as a Function of Five Macroscopic Parameters, Acta Mater., 2003, 51, p 3675–3686.

D.M. Saylor, B.S. El-Dasher, B.L. Adams, and G.S. Rohrer, Measuring the Five-Parameter Grain-Boundary Distribution from Observations of Planar Sections, Metall. Mater. Trans. A, 2004, 35(7), p 1981–1989.

S. Mahajan, C.S. Pande, M.A. Imam, and B.B. Rath, Formation of Annealing Twins in f.c.c. Crystals, Acta Mater., 1997, 45(6), p 2633–2638.

S. Mahajan, Critique of Mechanisms of Formation of Deformation, Annealing and Growth Twins: Face-Centered Cubic Metals and Alloys, Scr. Mater., 2013, 68(2), p 95–99. https://doi.org/10.1016/j.scriptamat.2012.09.011

N. Nayan, N.P. Gurao, S.V.S. Narayana Murty, A.K. Jha, B. Pant, S.C. Sharma and K.M. George, Microstructure and Micro-Texture Evolution during Large Strain Deformation of an Aluminum-Copper-Lithium Alloy AA 2195, Mater. Des., 2015, 65, p 862–868. https://doi.org/10.1016/j.matdes.2014.09.037

M. Rout, S. Biswas, R. Ranjan, S.K. Pal, and S.B. Singh, Deformation Behavior and Evolution of Microstructure and Texture During Hot Compression of AISI 304LN Stainless Steel, Metall. Mater. Trans. A, 2018, 49, p 864–880. https://doi.org/10.1007/s11661-017-4447-5

J.P. Hirth, The Influence of Grain Boundaries on Mechanical Properties, Met. Trans., 1972, 3(12), p 3047–3067. https://doi.org/10.1007/BF02661312.pdf

S. Chen, and Q. Yu, The Role of Low Angle Grain Boundary in Deformation of Titanium and Its Size Effect, Scr. Mater., 2019, 163, p 148–151. https://doi.org/10.1016/j.scriptamat.2018.10.054

G.S. Rohrer, Grain Boundary Energy Anisotropy: A Review, J. Mater. Sci., 2011, 46(18), p 5881–5895.

Y. Zhang, J. Yang, D. Xiao, D. Luo, C. Tuo, and H. Wu, Effect of Quenching and Tempering on Mechanical Properties and Impact Fracture Behavior of Low-Carbon Low-Alloy Steel, Metals (Basel), 2022, 12(7), p 2–13.

L.L. Li, Z.J. Zhang, P. Zhang, J.B. Yang, and Z.F. Zhang, Distinct Fatigue Cracking Modes of Grain Boundaries with Coplanar Slip Systems, Acta Mater., 2016, 120, p 120–129.

W. Sun, S. Wang, and M. Hong, Microstructure and Mechanical Properties of C10100 Copper/304 Stainless Steel Electron Beam Welded Joint, J. Phys. Conf. Ser., 2022, 2235(1), p 012043.

X.L. Wang, Z.Q. Wang, L.L. Dong, C.J. Shang, X.P. Ma, and S.V. Subramanian, New Insights into the Mechanism of Cooling Rate on the Impact Toughness of Coarse Grained Heat Affected Zone from the Aspect of Variant Selection, Mater. Sci. Eng. A, 2017, 704(May), p 448–458.

X. Li, X. Guan, Z. Jia, P. Chen, C. Fan, and F. Shi, Twin-Related Grain Boundary Engineering and Its Influence on Mechanical Properties of Face-Centered Cubic Metals: A Review, Metals Basel, 2023, 13(1), p 155.

Z. Zhuo, S. Xia, Q. Bai, and B. Zhou, The Effect of Grain Boundary Character Distribution on the Mechanical Properties at Different Strain Rates of a 316L Stainless Steel, J. Mater. Sci., 2018, 53(4), p 2844–2858.

O.V. Mishin, V.Y. Gertsman, I.V. Alexandrov, and R.Z. Valiev, Grain Boundary Character Distributions and Mechanical Properties of 304 Stainless Steel, Mater. Sci. Eng. A, 1996, 212(2), p 281–283.

S.I. Wright, M.M. Nowell, and D.P. Field, A Review of Strain Analysis Using Electron Back Scatter Diffraction, Microsc. Microanal., 2011, 17, p 316–329.

G. Su, Z. Yun, Y.C. Lin, D.G. He, S. Zhang, and Z.J. Chen, Microstructure Evolution and a Unified Constitutive Model of Ti-55511 Alloy Compressed at Stepped Strain Rates, Materials (Basel), 2021, 14(22), p 1–20.

H.W. Son, J.W. Lee, and S.K. Hyun, Mechanism of Grain Boundary Serration during Hot Deformation of AZ31 Alloy: Role of Grain Boundary Dislocations and Grain Boundary Sliding, Int. J. Plast., 2020, 125(September 2019), p 118–132. https://doi.org/10.1016/j.ijplas.2019.09.003

A. Hadadzadeh, F. Mokdad, M.A. Wells, and D.L. Chen, A New Grain Orientation Spread Approach to Analyze the Dynamic Recrystallization Behavior of a Cast-Homogenized Mg-Zn-Zr Alloy Using Electron Backscattered Diffraction, Mater. Sci. Eng. A, 2018, 709(October 2017), p 285–289. https://doi.org/10.1016/j.msea.2017.10.062

S. Biswas, D.I. Kim, and S. Suwas, Asymmetric and Symmetric Rolling of Magnesium: Evolution of Microstructure, Texture and Mechanical Properties, Mater. Sci. Eng. A, 2012, 550, p 19–30. https://doi.org/10.1016/j.msea.2012.03.099

M. Detrois, R.L. Goetz, R.C. Helmink, and S. Tin, The Role of Texturing and Recrystallization During Grain Boundary Engineering of Ni-Based Superalloy RR1000, J. Mater. Sci., 2016, 51(11), p 1–17.

M.A. Meyers and L.E. Murr, A Model for the Formation of Annealing Twins in F.C.C Metals and Alloys, Acta Metall., 1978, 26(6), p 951–962.

N. Bozzolo and M. Bernacki, Viewpoint on the Formation and Evolution of Annealing Twins During Thermomechanical Processing of FCC Metals and Alloys, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2020, 51(6), p 2665–2684. https://doi.org/10.1007/s11661-020-05772-7

H. Gleiter, The Formation of Annealing Twins, Acta Metall., 1969, 17(12), p 1421–1428.

M. Rout, S.K. Pal, and S.B. Singh, Post-Hot-Deformation Microstructure Development in Austenitic Stainless Steel, Mater. Chem. Phys., 2023, 295(22), p 127064. https://doi.org/10.1016/j.matchemphys.2022.127064

X.M. Chen, Y.C. Lin, and F. Wu, EBSD Study of Grain Growth Behavior and Annealing Twin Evolution after Full Recrystallization in a Nickel-Based Superalloy, J. Alloys Compd., 2017, 724, p 198–207. https://doi.org/10.1016/j.jallcom.2017.07.027

H. Beladi, A. Ghaderi, and G.S. Rohrer, Five-Parameter Grain Boundary Characterization of Randomly Textured AZ31 Mg Alloy, Philos. Mag., 2020, 100(4), p 456–466. https://doi.org/10.1080/14786435.2019.1692154

S.I. Wright and R.J. Larsen, Extracting Twins from Orientation Imaging Microscopy Scan Data, J. Microsc., 2002, 205(3), p 245–252.

D. Ponge and G. Gottstein, Necklace Formation during Dynamic Recrystallization: Mechanisms and Impact on Flow Behavior, Acta Mater., 1998, 46(1), p 69–80. https://doi.org/10.1016/S1359-6454(97)00233-4

M. Rout, S.B. Singh, and S.K. Pal, Characterization of Post-Hot-Deformation Annealing Twins Developed in 304LN Austenitic Stainless Steel, Asia Steel International Conference, (Bhubaneswar, India), 2018.

A. Telang, A.S. Gill, D. Tammana, X. Wen, M. Kumar, S. Teysseyre, S.R. Mannava, D. Qian, and V.K. Vasudevan, Surface Grain Boundary Engineering of Alloy 600 for Improved Resistance to Stress Corrosion Cracking, Mater. Sci. Eng. A, 2015, 648, p 280–288. https://doi.org/10.1016/j.msea.2015.09.074

P. Bhuyan, S. Sanyal, V.S. Sarma, B. de Boer, R. Mitra, and S. Mandal, A Novel Approach Combining Grain Boundary Engineering and Grain Boundary Serration to Enhance High-Temperature Hot Corrosion Resistance in Alloy 617, Materialia, 2022, 23(February), p 101451. https://doi.org/10.1016/j.mtla.2022.101451

M. Kumar, W.E. King, and A.J. Schwartz, Modifications to the Microstructural Topology in f.c.c. Materials through Thermomechanical Processing, Acta Mater., 2000, 48(9), p 2081–2091.

X.J. Guan, F. Shi, H.M. Ji, and X.W. Li, Gain Boundary Character Distribution Optimization of Cu-16at.%Al Alloy by Thermomechanical Process: Critical Role of Deformation Microstructure, Mater. Sci. Eng. A, 2019, 765(August).

B. Aashranth, D. Samantaray, M. Arvinth-Davinci, S. Murugesan, U. Borah, S.K. Albert, and A.K. Bhaduri, A Micro-Mechanism to Explain the Post-DRX Grain Growth at Temperatures > 0.8Tm, Mater Charact, 2018, 136(17), p 100–110. https://doi.org/10.1016/j.matchar.2017.12.010

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rout, M., Singh, S.B. & Pal, S.K. Grain Boundary Development in Post-hot-deformed Austenitic Stainless Steel. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09039-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09039-1